Method for preparing porous material with asymmetric structure

An asymmetric structure and porous material technology, applied in the field of porous material preparation, can solve problems such as dust pollution, environmental and operator hazards, and increased element content of porous materials, achieving high utilization rate, wide application range, and excellent mechanical properties and the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

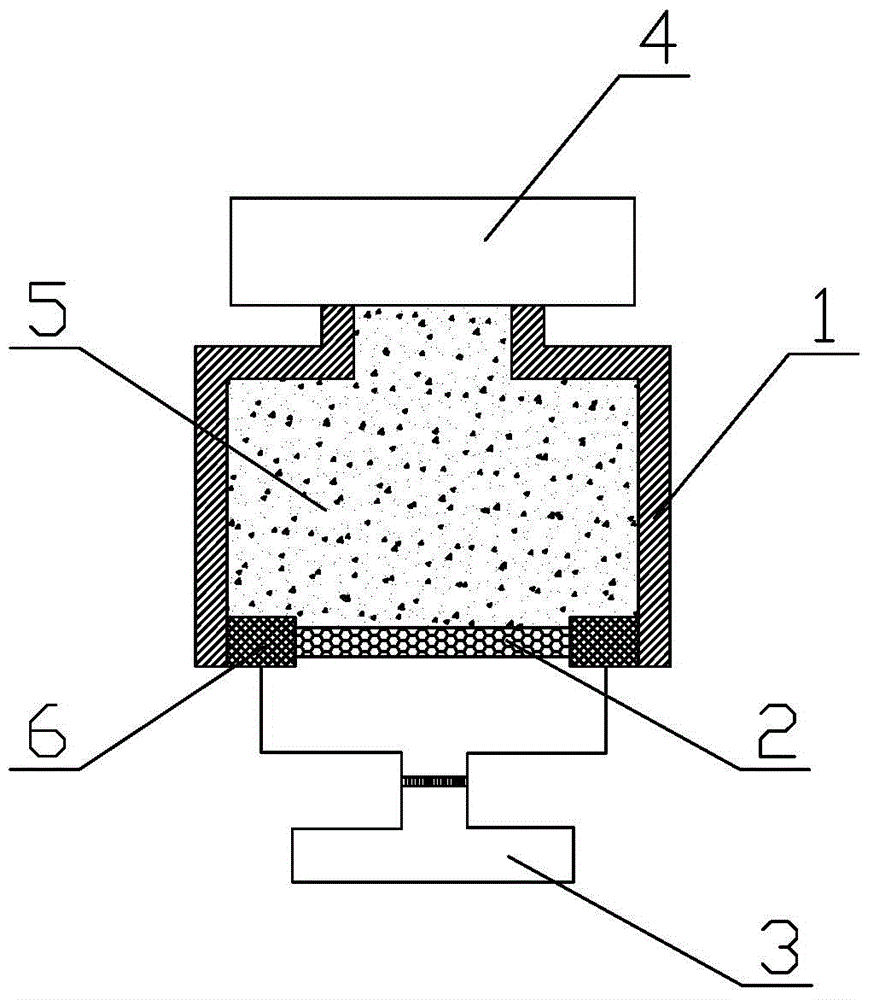

[0033] To prepare an asymmetric structure on the surface of a flat porous material:

[0034] Step one, such as figure 1 As shown, a clamp 6 is used to fix the porous support 2 in the closed deposition chamber 1, and the side of the porous support 2 to be deposited is communicated with the powder feeder 4 at one end of the deposition chamber 1. The other side is connected to the vacuum pump 3 located at the other end of the deposition chamber 1; the porous support is a Φ30×2mm flat 316L porous support with a pore size of 20μm and an air permeability coefficient of 218m 3 / m 2 ·KPa·h;

[0035] Step 2: Add the powder material 5 to be deposited into the powder feeder 4; the powder material is D 50 =4.5μm spherical 316L powder;

[0036] Step 3: Turn on the vacuum pump 3 so that the pressure difference between the two sides of the porous support 2 is 800 Pa, then turn on the powder feeder 4, and the powder material 5 in the powder feeder 4 is transported to the side of the porous support 2...

Embodiment 2

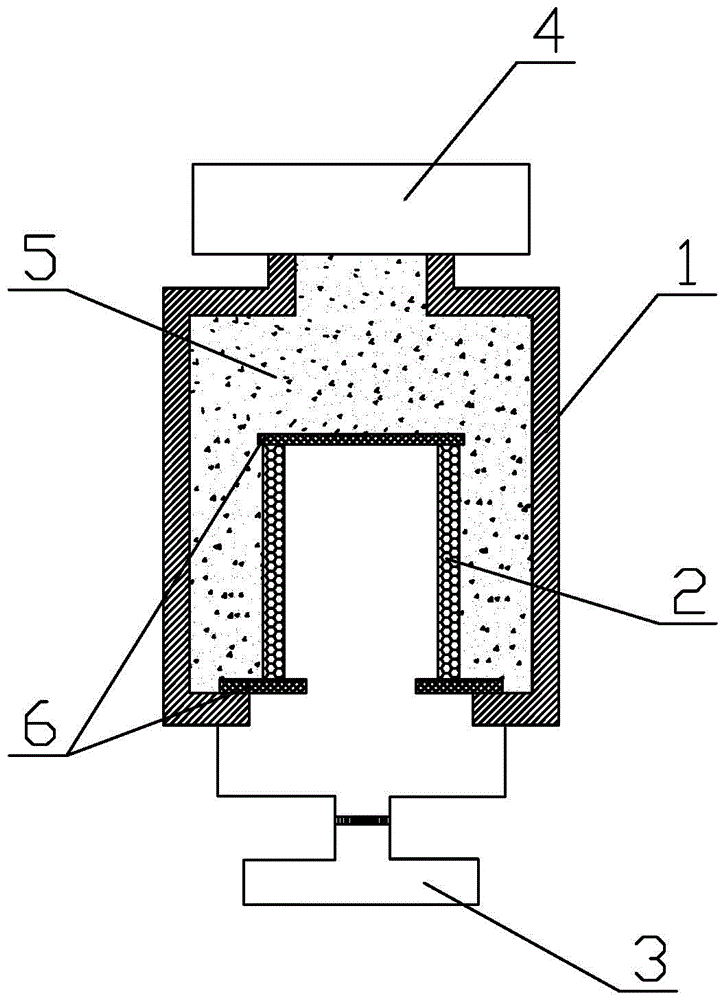

[0040] Prepare an asymmetric structure on the outer wall of the tubular porous material:

[0041] Step one, such as image 3 As shown, a clamp 6 is used to fix the porous support 2 in the closed deposition chamber 1, and the side (outer wall) of the porous support 2 to be deposited is connected to the powder feeder 4 at one end of the deposition chamber 1, and the porous support The other side (inner wall) of the body 2 is in communication with the vacuum pump 3 at the other end of the deposition chamber 1; the porous support is a tubular 316L porous support of Φ50×150mm, with a pore size of 28μm and an air permeability coefficient of 195m 3 / m 2 ·KPa·h;

[0042] Step 2: Add the powder material 5 to be deposited into the powder feeder 4; the powder material is D 50 =12.4μm spherical 316L powder;

[0043] Step 3: Turn on the vacuum pump 3 so that the pressure difference between the two sides of the porous support 2 is 400 Pa, then turn on the powder feeder 4, and the powder material 5...

Embodiment 3

[0047] To prepare an asymmetric structure on the inner wall of the tubular porous material:

[0048] Step one, such as Figure 5 As shown, a clamp 6 is used to fix the porous support 2 in the closed deposition chamber 1, and the side (inner wall) of the porous support 2 to be deposited is connected to the powder feeder 4 at one end of the deposition chamber 1, and the porous support The other side (outer wall) of the body 2 is in communication with the vacuum pump 3 at the other end of the deposition chamber 1; the porous support is a tubular 316L porous support of Φ60×150mm, with a pore size of 20μm and an air permeability coefficient of 225m 3 / m 2 ·KPa·h;

[0049] Step 2: Add the powder material 5 to be deposited into the powder feeder 4; the powder material is D 50 =4.5μm spherical 316L powder;

[0050] Step 3: Turn on the vacuum pump 3 so that the pressure difference between the two sides of the porous support 2 is 800 Pa, then turn on the powder feeder 4, and the powder materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| filtration accuracy | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com