Wet desulphurization system with multi-stage humidification demisting device

A demisting device and wet desulfurization technology, applied in the field of purification devices in thermal power plants, can solve the problems of no space for electric dust removal in power plants, high power consumption of high-voltage DC power supply, high operation and maintenance costs, and achieve huge environmental benefits and Economic benefits, short construction period, and convenient equipment maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

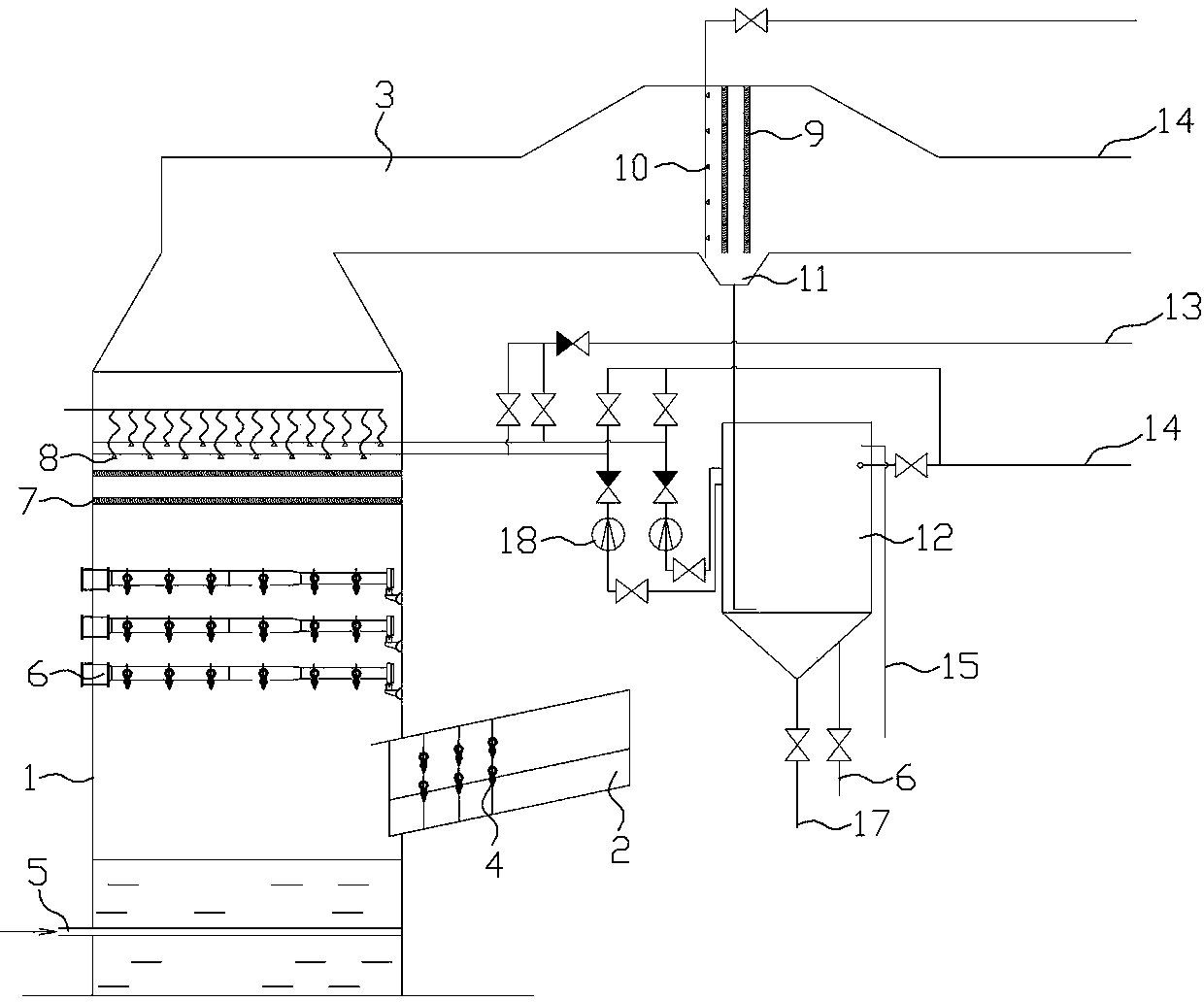

[0014] like figure 1 As shown, it includes an absorption tower 1, the absorption tower 1 is provided with a flue gas inlet 2, a flue 3, an oxidation air inlet 5, a spray layer 6 and a demister 7, and the flue gas inlet 2 is provided with a flue spray device 4 , 0.3-1.0m behind the demister 7 is provided with a humidification nozzle 8, a final stage demister 9 is provided in the flue 4-10m behind the humidification nozzle 8, and a flushing device is provided before the final demister 9. The flushing nozzle 10 of the final demister 9.

[0015] The bottom of the final demister 9 is provided with a sump 11 connected to the humidification water circulation sedimentation water tank 12, the water for the humidification nozzle 8 and the flushing nozzle 10 comes from the process water pipeline 14, and the humidification water circulation sedimentation water tank 12 is equipped with an overflow pipe 15 and manual sewage discharge Pipe 16, continuous small flow sewage pipe 17, and conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com