Preparation method of carboxyl functionalized hyperbranched magnetic mesoporous silica composite microspheres

A technology of mesoporous silica and carboxyl functionalization, applied in the preparation of microspheres, microcapsule preparations, etc., can solve problems such as damage to healthy cells, adverse side effects, etc., and achieve effective and stable precious metal catalysts, high magnetic responsiveness, and good control effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

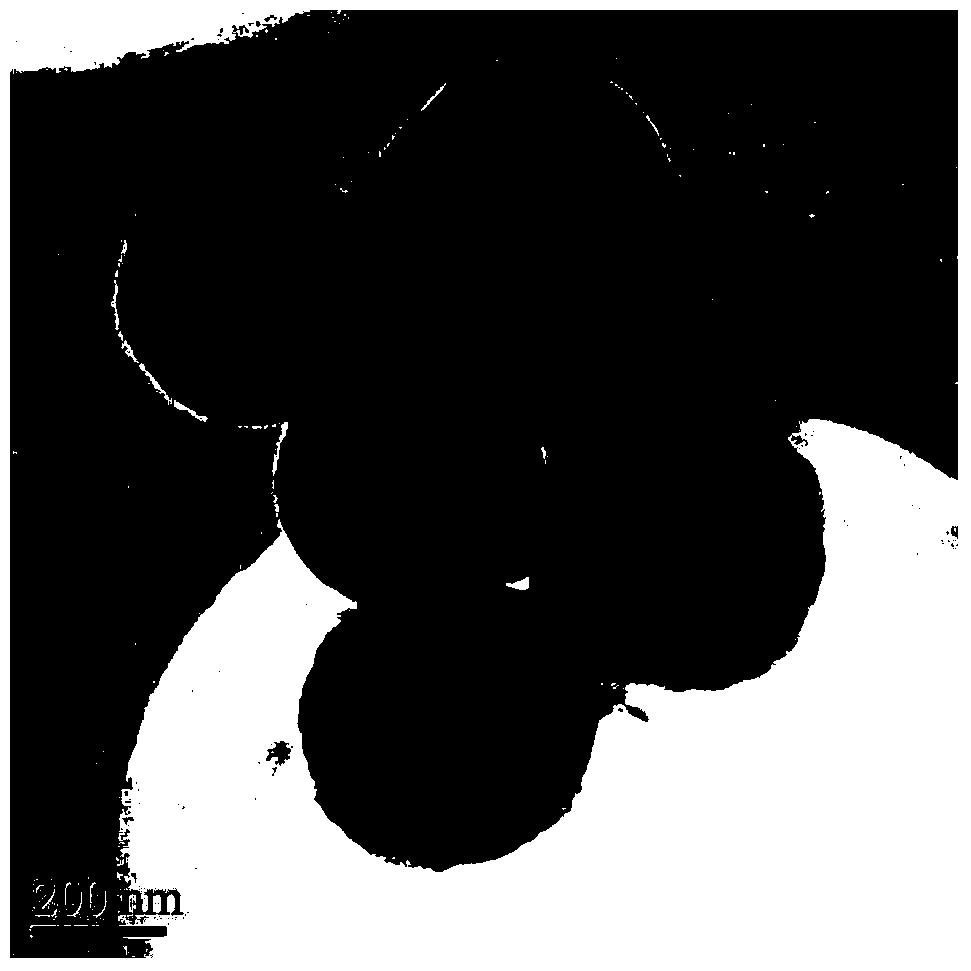

[0021] Example 1: Superparamagnetic Fe 3 o 4 Preparation of nanoparticles

[0022] FeCl 3 ·6H 2 O (13.0g), trisodium citrate (5g) and sodium acetate (20g) were dissolved in 150ml ethylene glycol with the assistance of ultrasound, continued to stir for 1h under mechanical stirring, and transferred to three 50ml stainless steel PTFE high pressure In the reaction kettle, keep at 200°C for 10h. The product was washed 2 to 3 times with ethanol, and then washed with distilled water until neutral. Finally, the product was magnetically separated by an external magnetic field, and kept in a vacuum oven at 45°C for 24h.

Embodiment 2

[0023] Example 2: Magnetic core-shell Fe 3 o 4 nSiO 2 Preparation of composite microspheres

[0024] Ultrasonic disperse 0.6g superparamagnetic Fe3O4 nanoparticles in a mixture of 20ml pure water and 30ml absolute ethanol to form a uniform dispersion system, then quickly add 2ml NH 3 ·H 2 O, stirred mechanically at 300 rpm for 30 min, added 1.0 g of TEOS dropwise within 1 min, and kept stirring at room temperature for 10 h. The product was simply magnetically separated by an external magnetic field, washed several times with ethanol and distilled water, and finally kept in a vacuum oven at 45°C for 24h.

Embodiment 3

[0025] Example 3: Double-shell magnetic mesoporous Fe 3 o 4 nSiO 2 mSiO 2 Preparation of composite microspheres

[0026] 1.2g of the magnetic Fe prepared above 3 o 4 SiO 2 The core-shell composite microspheres and 3.6g template agent CTAB were ultrasonically dispersed in a mixture of 80ml pure water and 160ml absolute ethanol to form a uniform dispersion system, and then 8ml NH 3 ·H 2 O, mechanically stirred at 300 rpm for 30 min. The rotational speed was adjusted to 360 rpm, 4.0 g of TEOS was added dropwise within 3 min, and the reaction was kept stirring at room temperature for 10 h. The product was simply magnetically separated by an external magnetic field, washed several times with ethanol and distilled water, and finally kept in a vacuum oven at 45°C for 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com