Synthesis method of peroxide mimic enzyme nano-catalysis particles

A technology of peroxide and nano-catalysis, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem that the function of optical signal converter cannot be reflected, static electricity Repulsion instability and other problems, to achieve a significant surface plasmon resonance absorption peak and low price, enhance the effect of optical signal conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

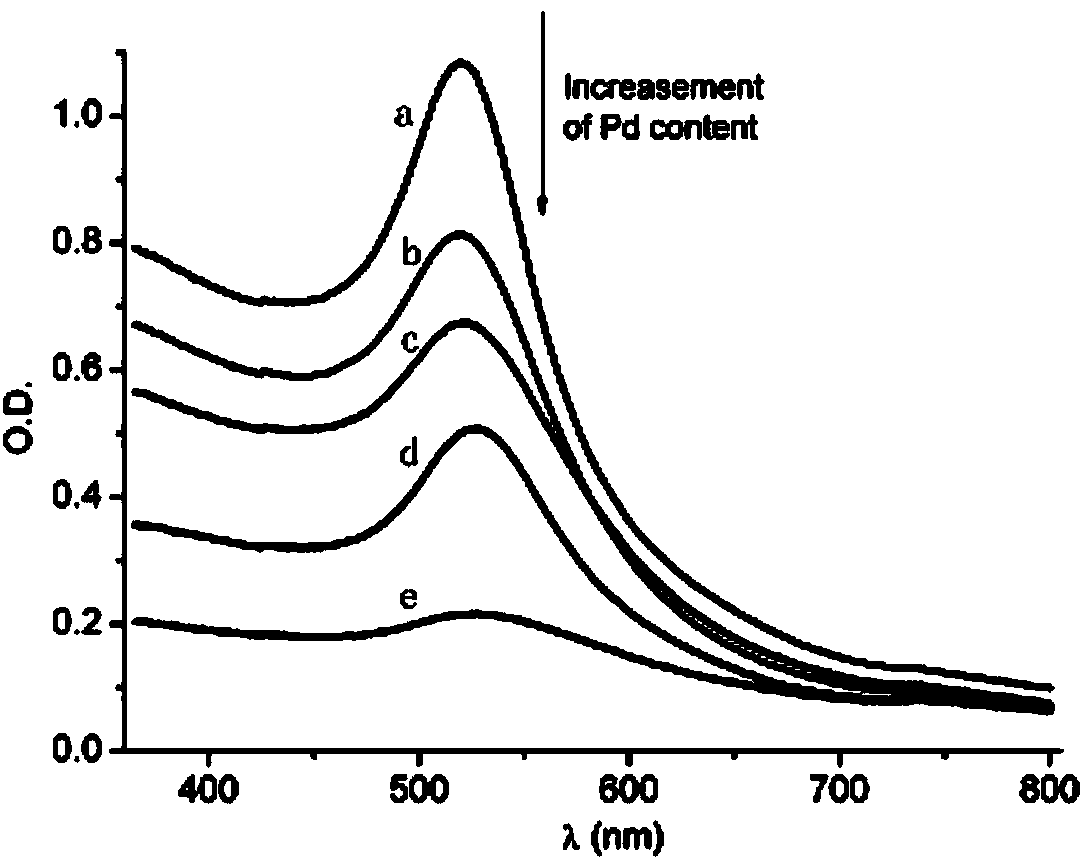

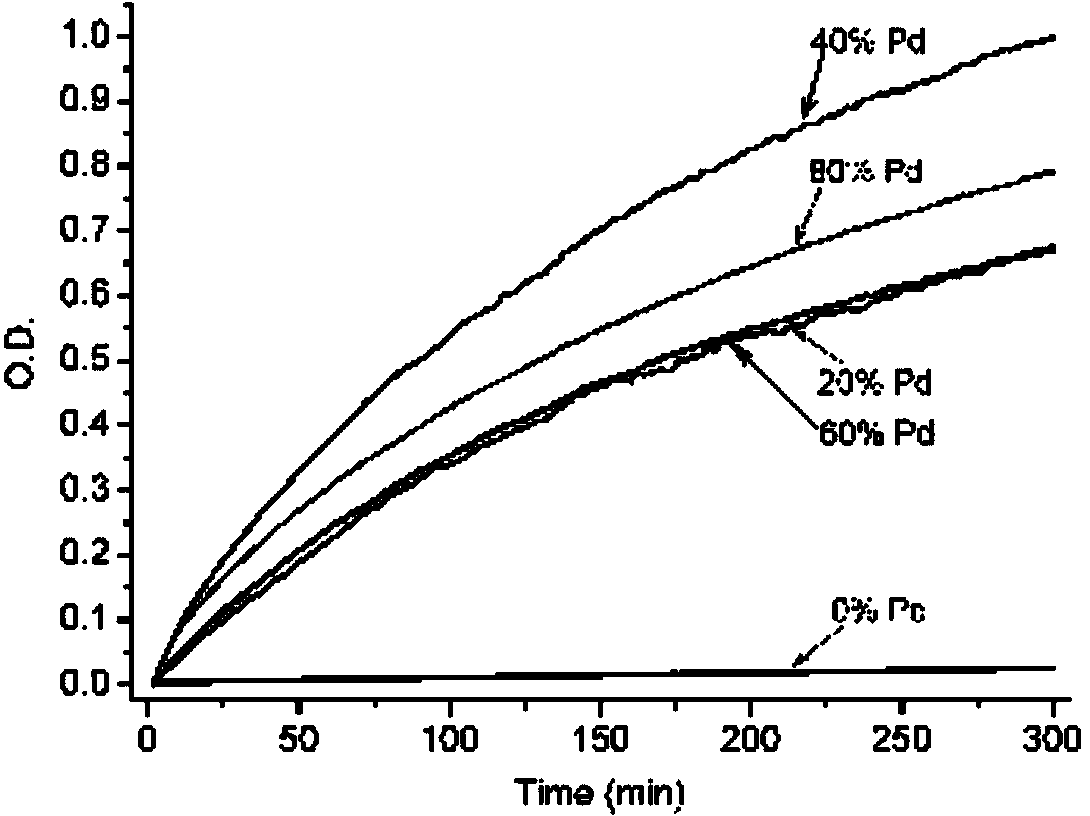

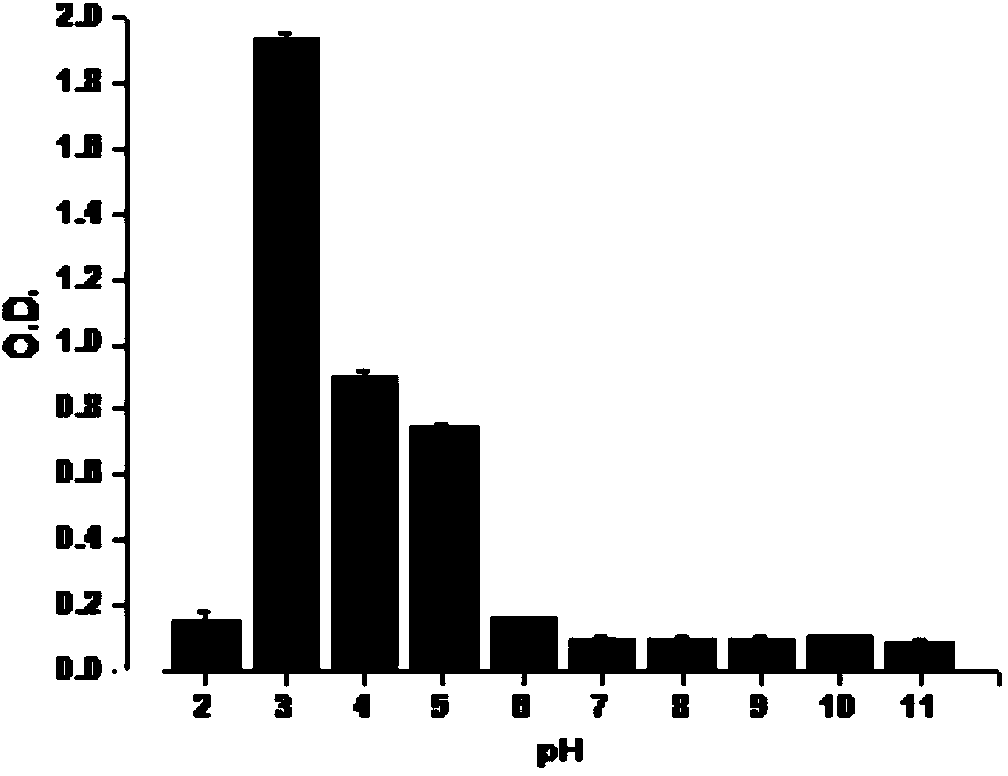

[0029] All the experimental containers involved in this experiment were washed sequentially with tap water, reverse osmosis water, soaked in MilliQ water overnight, washed with aqua regia, soaked in MilliQ water, washed, and dried in an oven. In a three-neck round bottom flask with a stirrer and a reflux tube, add 500 mM HAuCl with a concentration of 0.8 mM prepared with MilliQ water 4 solution with a concentration of 0.2mMNa 2 PdCl 4 Solution, the middle port of the three-neck round bottom flask is connected to the stirrer, one oblique port is connected to the reflux pipe, and the other oblique port is plugged with a ground glass stopper. Continue to heat the solution in the three-necked round-bottom flask, and at the same time turn on the agitator to stir the solution. After the solution boils, when the reflux flow in the reflux tube tends to be stable, pour 50 mL of the previously prepared sodium citrate solution with a concentration of 38.8 mM into the reaction The final...

Embodiment 2

[0032] All the experimental containers involved in this experiment were washed sequentially with tap water, reverse osmosis water, soaked in MilliQ water overnight, washed with aqua regia, soaked in MilliQ water, washed, and dried in an oven. Add 500 mL of 0.6 mM HAuCl prepared with MilliQ water to a three-necked round bottom flask with a stirrer and a reflux tube 4 solution and 0.4mMPd(NO 3 ) 2Solution, the middle port of the three-neck round bottom flask is connected to the stirrer, one oblique port is connected to the reflux pipe, and the other oblique port is plugged with a ground glass stopper. Continue to heat the solution in the three-neck round bottom flask, and at the same time turn on the stirrer to stir the solution. After the solution boils, when the reflux flow in the reflux tube tends to be stable, pour 50mL of sodium citrate solution with a concentration of 38.8mL prepared in advance into the reaction The final concentration of sodium citrate in the container ...

Embodiment 3

[0035] All the experimental containers involved in this experiment were washed sequentially with tap water, reverse osmosis water, soaked in MilliQ water overnight, washed with aqua regia, soaked in MilliQ water, washed, and dried in an oven. Add 500 mL of 0.4 mM HAuCl prepared with MilliQ water to a three-necked round bottom flask with a stirrer and a reflux tube 4 solution and PdSO at a concentration of 0.6mM 4 Solution, the middle port of the three-neck round bottom flask is connected to the stirrer, one oblique port is connected to the reflux pipe, and the other oblique port is plugged with a ground glass stopper. Continue to heat the solution in the three-necked round-bottom flask, and at the same time turn on the agitator to stir the solution. After the solution boils, when the reflux flow in the reflux tube tends to be stable, pour 50 mL of the previously prepared sodium citrate solution with a concentration of 38.8 mM into the reaction The final concentration of sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com