Miniaturized multipurpose treatment equipment for separating and dewatering restaurant garbage

A technology of food waste and processing equipment, which is applied in the field of high-efficiency processing devices, can solve problems such as large volume, and achieve the effects of high processing efficiency, good solid-liquid separation, and efficient sorting and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

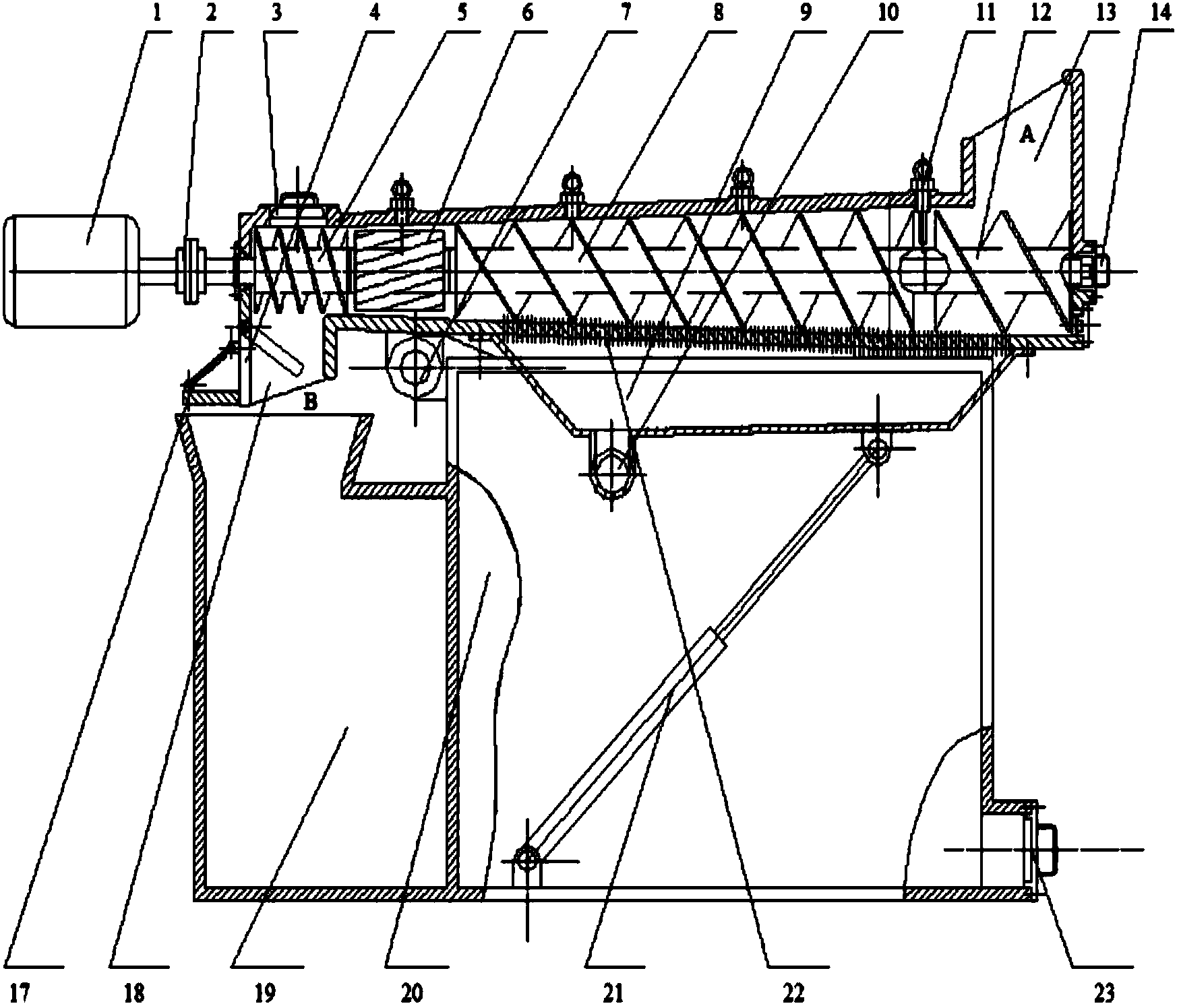

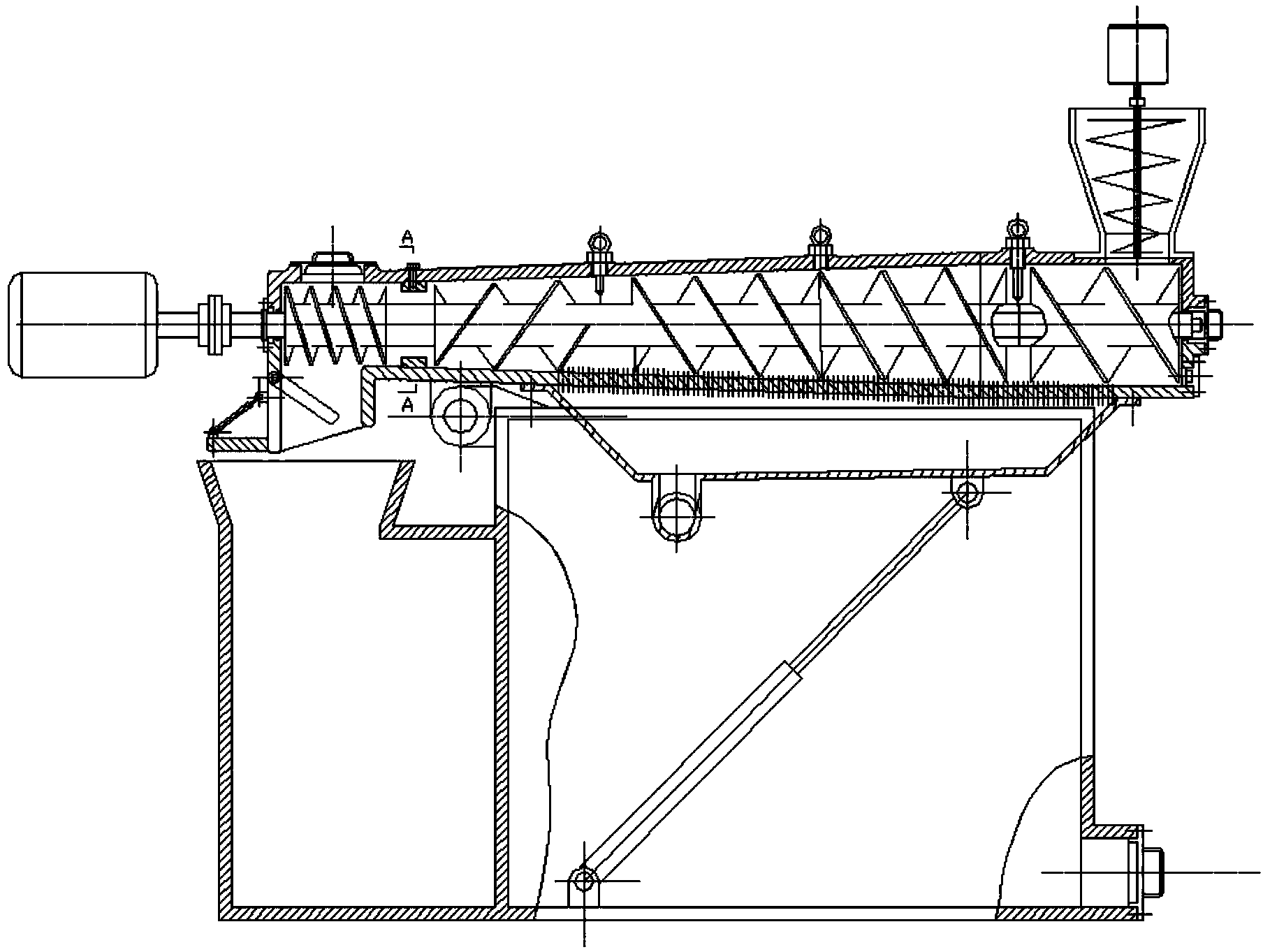

[0041] Figure 1 is an embodiment of the present invention. One end of the hydraulic support adjustment mechanism is fixed to the lower base of the storage tank, and the other end is fixed to the screw dehydrating machine barrel pair to adjust the inclination angle of the machine barrel pair. The motor is fixedly connected on the barrel pair. There is a feeding port on the side of the machine barrel, which is used to send water-containing materials such as food waste to the inside of the machine barrel for dehydration. The other side of the barrel pair is equipped with an outlet adjustment device, which controls the pressure of the water-containing material in the barrel pair by adjusting the closure of the rotatable baffle. A filter plate and a liquid collection tank are installed under the lower barrel. When the hydraulic support adjustment mechanism adjusts the auxiliary inclination angle of the barrel to -45°, the position of the auxiliary feeding port of the barrel is at...

Embodiment 2

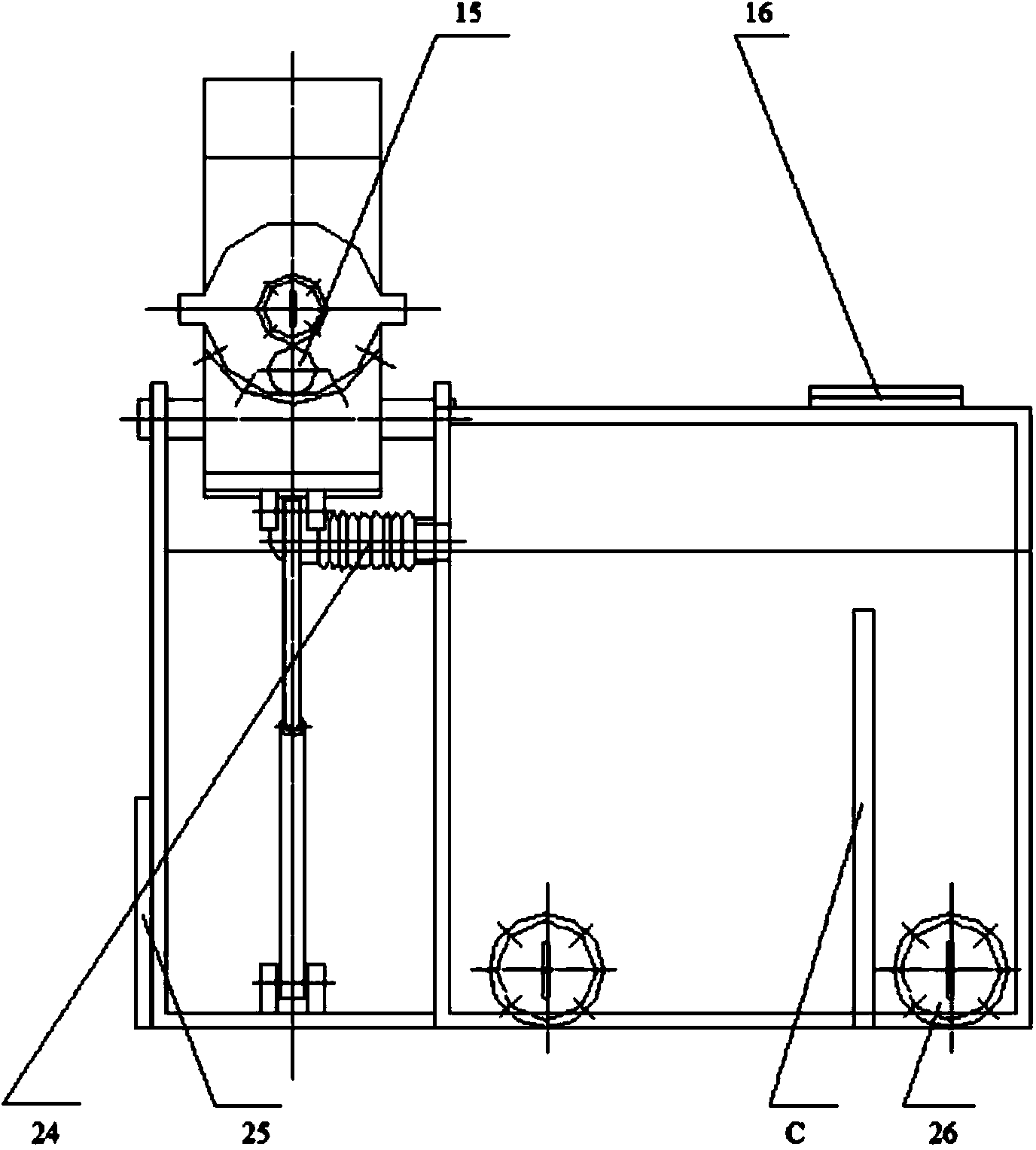

[0048] Fig. 2 is embodiment 2 of the present invention, for utilizing the present invention to carry out deep processing of seafood wastes such as fish and shrimp. The difference between embodiment 2 and embodiment 1 is that in embodiment 2, in order to realize the crushing of materials, two crushing device insertion points are set between the equal-diameter conveying thread section and the variable-diameter thread section, and in the variable-diameter thread section. It's not the bag breaker hook that threads in, but the breaker knife. In order to improve the dehydration effect, a section of reverse thread and a pressure building retaining ring are set in the variable diameter thread section to increase the ability of the screw to build pressure on the material. The filter hole diameter of the filter plate is 2mm. The feeding mode of embodiment 2 is also different from embodiment 1, uses the screw forced feeding device to carry out forced feeding, to improve the processing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com