Method for preparing 3-methyl-1,3-ferrocenyl propylene-1-one

A technology of bisferrocene-based propylene and acetyl ferrocene is applied in chemical instruments and methods, metallocenes, organic chemistry, etc., and can solve the problems of long reaction time, troublesome post-processing, low yield, etc. The effect of short time, low equipment requirements and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

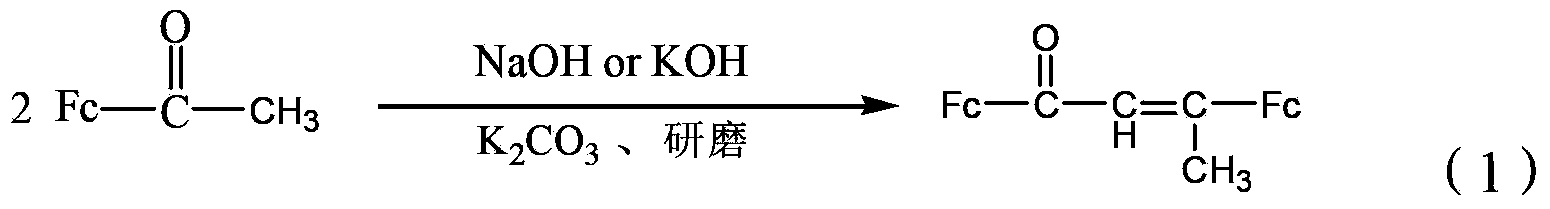

Image

Examples

Embodiment 1

[0023] In the first step, add 2mmol acetyl ferrocene, 1.5mmol NaOH and 3.5mmol K to the mortar 2 CO 3 , grind for 10min, then stand still for 2h to obtain the mixture;

[0024] In the second step, add 50mL of water to the mixture to disperse evenly, then suction filter, wash the filter cake with water until its pH = 7, and dry it at room temperature to obtain a dark red powder that is 3-methyl-1,3- Bisferrocenylpropen-1-one, the yield is 85%; m.p is 120~121℃.

[0025] IR (KBr) (cm -1 ): 3091, 1109, 1006, 819 (C-H of ferrocene ring); 1637 (C=O); 1586 (C=C).

Embodiment 2

[0027] In the first step, add 2mmol acetyl ferrocene, 2mmol KOH and 2.5mmol K to the mortar 2 CO 3 , grind for 15min, then stand still for 1.5h to obtain the mixture;

[0028] In the second step, add 65mL of water to the mixture to disperse evenly, then filter with suction, wash the filter cake with water until its pH=6, and dry it at room temperature to obtain a dark red powder that is 3-methyl-1,3- Bisferrocenyl propen-1-one, the yield is 89%; m.p is 120~121℃.

Embodiment 3

[0030] In the first step, add 2mmol acetyl ferrocene and 3.5mmol NaOH to the mortar, grind for 20min, and then let stand for 2h to obtain the mixture;

[0031] In the second step, add 60mL of water to the mixture to disperse evenly, then filter with suction, wash the filter cake with water until its pH=7, and dry it at room temperature to obtain a dark red powder that is 3-methyl-1,3- Bisferrocenyl propen-1-one, the yield is 92%; m.p is 120~121℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com