Gas-phase rust preventive oil and preparation method thereof

A gas-phase anti-rust and oil technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of affecting the service life of components, large effective mist particles, and the technical surface of components cannot be completely covered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] A gas-phase anti-rust oil, comprising by weight components: 50 parts of No. 32 engine oil, 5 parts of octadecylamine, 3 parts of sodium petroleum sulfonate, 1 part of barium petroleum sulfonate, 2 parts of sodium benzoate, and 3 parts of polyvinyl alcohol , 1 part of thionyl octyl zinc, 2 parts of polyether, 1 part of sorbitan monooleate, 2 parts of tributylamine caprylate, 1 part of lauryl alcohol, 2 parts of amino silicone oil.

[0010] Add No. 32 engine oil into the reaction kettle, heat it to 80-90°C and keep it warm, then add octadecylamine, sodium petroleum sulfonate, barium petroleum sulfonate, sodium benzoate, polyvinyl alcohol, thionyl octyl zinc, polyether , Sorbitan monooleate, tributylamine caprylate, lauryl alcohol, and amino silicone oil were slowly added into the reaction kettle, stirred while adding, and kept stirring in the reaction kettle at 90°C for 2 hours after the addition, to make gas-phase antirust oil.

Embodiment 2

[0012] A kind of vapor phase antirust oil, comprising by weight components: 65 parts of No. 32 machine oil, 8 parts of octadecylamine, 4 parts of sodium petroleum sulfonate, 3 parts of barium petroleum sulfonate, 3 parts of sodium benzoate, 5 parts of polyvinyl alcohol , 2 parts of thionyl octyl zinc, 4 parts of polyether, 3 parts of sorbitan monooleate, 3 parts of tributylamine caprylate, 4 parts of lauryl alcohol, 3 parts of amino silicone oil.

[0013] Add No. 32 engine oil into the reaction kettle, heat it to 80-90°C and keep it warm, then add octadecylamine, sodium petroleum sulfonate, barium petroleum sulfonate, sodium benzoate, polyvinyl alcohol, thionyl octyl zinc, polyether , Sorbitan monooleate, tributylamine caprylate, lauryl alcohol, and amino silicone oil were slowly added into the reaction kettle, stirred while adding, and kept stirring in the reaction kettle at 80°C for 2 hours after the addition to make gas-phase antirust oil.

Embodiment 3

[0015] A kind of vapor phase antirust oil, comprising by weight components: 80 parts of No. 32 machine oil, 10 parts of octadecylamine, 5 parts of sodium petroleum sulfonate, 4 parts of barium petroleum sulfonate, 5 parts of sodium benzoate, 6 parts of polyvinyl alcohol , 3 parts of thionyl octyl zinc, 6 parts of polyether, 5 parts of sorbitan monooleate, 4 parts of tributylamine caprylate, 6 parts of lauryl alcohol, 5 parts of amino silicone oil.

[0016] Add No. 32 engine oil into the reaction kettle, heat it to 80-90°C and keep it warm, then add octadecylamine, sodium petroleum sulfonate, barium petroleum sulfonate, sodium benzoate, polyvinyl alcohol, thionyl octyl zinc, polyether , Sorbitan monooleate, tributylamine caprylate, lauryl alcohol, and amino silicone oil were slowly added into the reaction kettle, and stirred while adding. After the addition, kept stirring at 85°C for 2 hours in the reaction kettle to make gas-phase antirust oil.

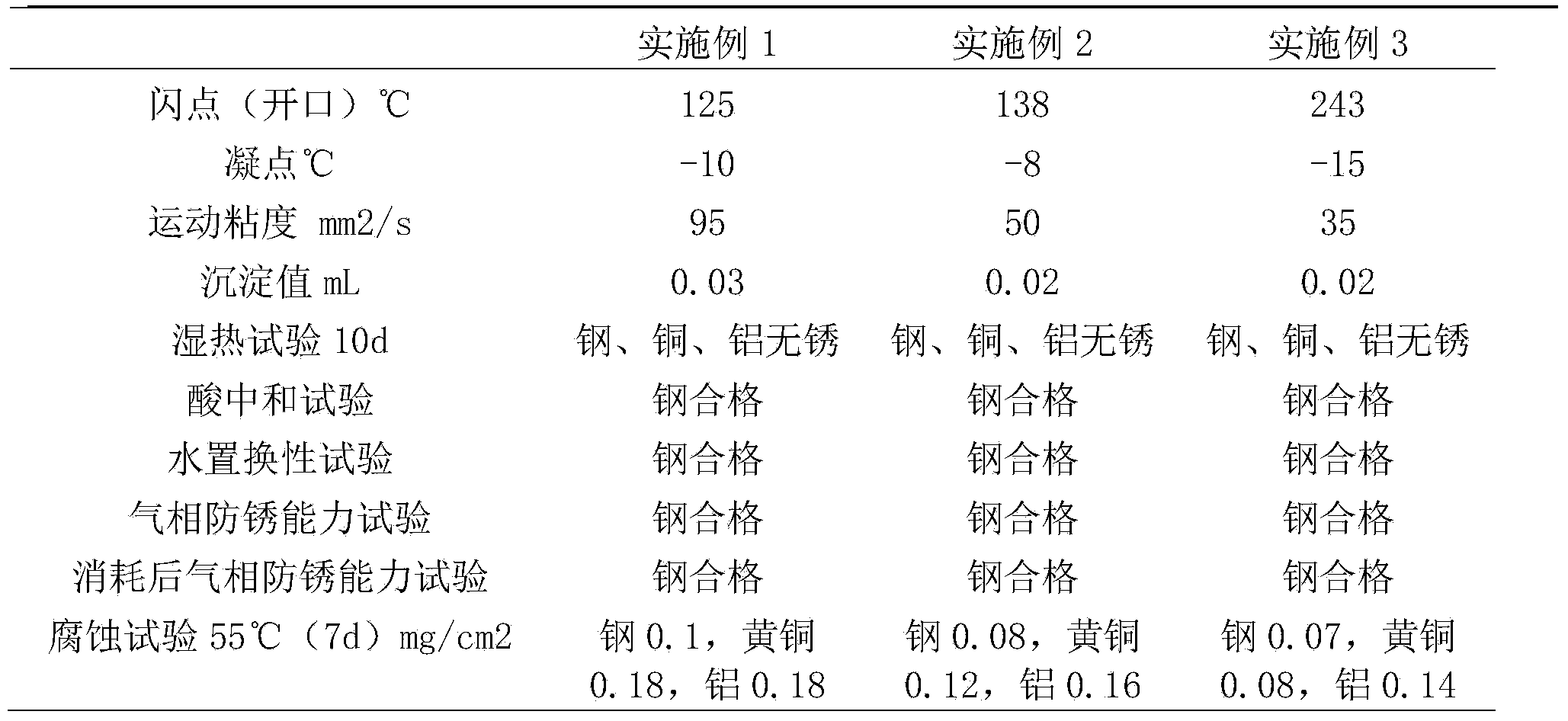

[0017] Embodiment 1 to 3 gaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com