LED (light emitting diode) lamp tube with front-mounted light and heat-conducting glass pipe lens and manufacturing method of LED lamp tube

A technology of LED lamp tubes and LED chips, which is applied to the parts of lighting devices, cooling/heating devices of lighting devices, light sources, etc., and can solve the problems of high integrated power of lighting sources, limited selection of heat dissipation treatment methods, and increased processing difficulty, etc. problems, achieve the effect of eliminating glare and light spots, simple and convenient construction and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] The specific implementation method comprises the following steps:

[0022] a. Put the COMMB—LED light source module with exposed non-light-emitting surface after solid crystal, wire bonding, and glue dispensing into the serial-parallel tooling for serial-parallel soldering and connection.

[0023] b. Install the diffuser film axially into the glass tube along the inner wall of the light-emitting end of the glass tube.

[0024] c. Place the COMMB—LED light source assembly with the light-emitting surface facing the non-closed end of the plastic profile, and put it into the groove of the plastic profile.

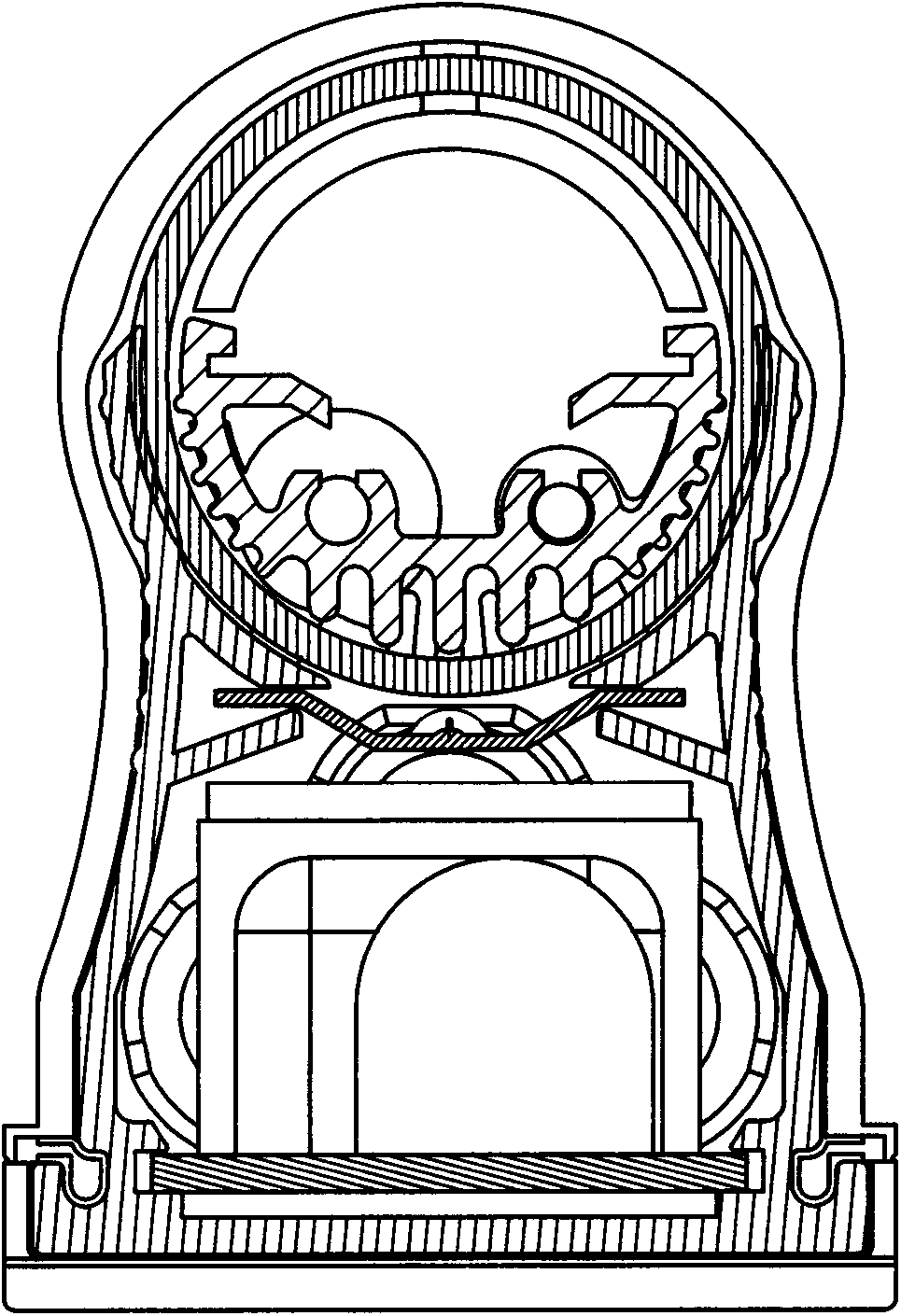

[0025] d. Press the heat-conducting and light-conducting glass tube into the non-enclosed insulating profile along the opening direction of the non-enclosed insulating profile, so that it contacts and fits with the spherical lens on the COMMB-LED light source board.

[0026] e. After injecting flexible hot-melt colloid into the apron groove of the insulating connecting ...

specific Embodiment

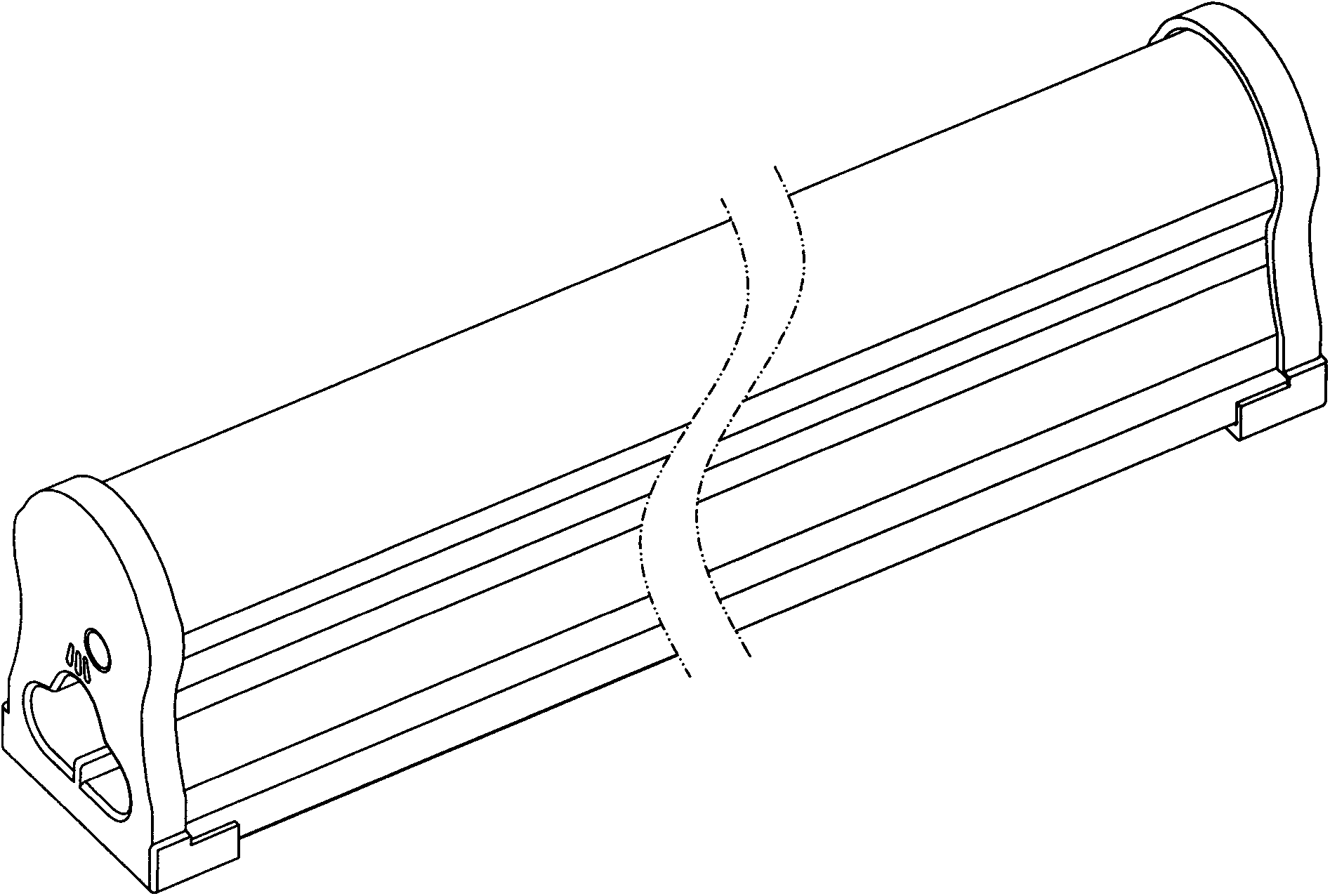

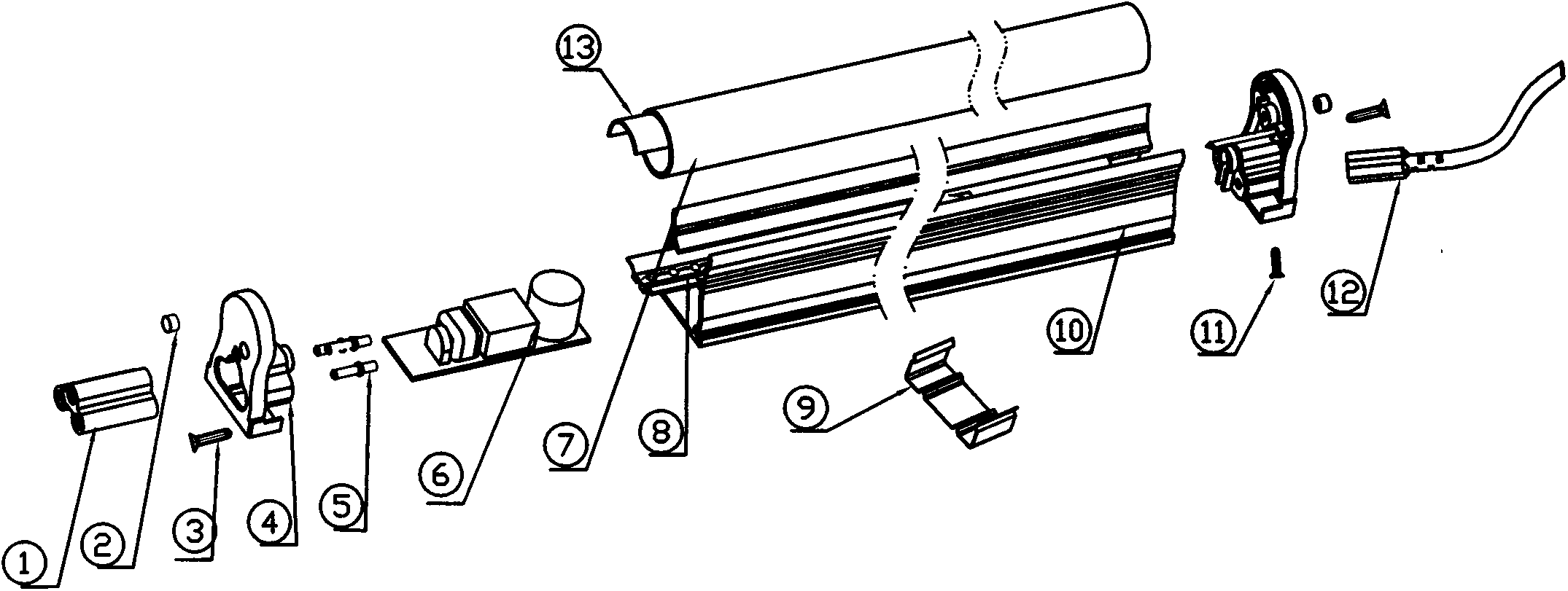

[0035] Such as figure 1 , 2As shown, an LED lamp tube with a front light-conducting and heat-conducting glass tube lens includes: 1. The middle column is used to complete the steel conductive connection between the LED fluorescent tubes connected in parallel and the LED fluorescent tubes. 2. The screw cover is used to complete the closure of the locking screw head on the end face of the LED fluorescent tube. 3. The end face locking screw is used to complete the axial locking of the end of the LED fluorescent tube. 4. LED fluorescent tube end cover, used to complete the end support of plastic profiles and glass tubes. 5. The copper needle electrode is used to complete the introduction of the external circuit of the LED constant current power supply. 6. Constant current power supply, which transforms and rectifies the mains alternating current to deliver the constant current to the COMMB—LED light source assembly. 7. Glass tube: It is used to complete the heat conduction of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap