Intelligent alternating current contactor capable of being controlled digitally and dynamically in whole process

An AC contactor, dynamic control technology, applied in relays, electrical components, circuits, etc., can solve the problems of inability to directly control the excitation state of the contactor, restrict the effective control of the contactor, difficult control strategies, etc. Contact wear, small loss, reducing the effect of core and contact bounce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the accompanying drawings and embodiments.

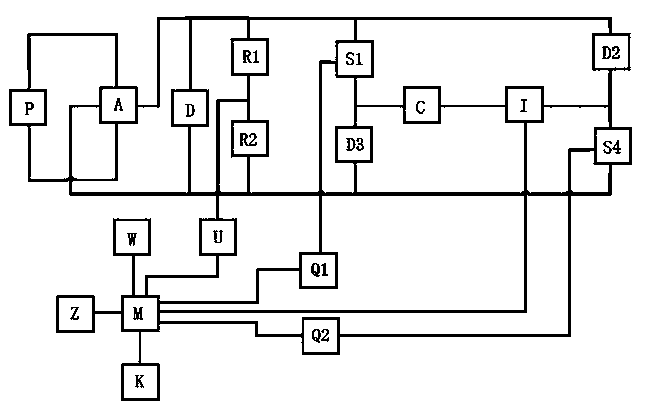

[0029] See figure 1 , this embodiment provides a digital whole-process dynamic control intelligent AC contactor, including an AC power supply P, characterized in that: it also includes a digital control unit M, the AC power supply P after the rectifier module A and the filter capacitor D The output terminal of the DC is connected to one end of the resistor R1, the first end of the first power electronic switch S1 and one end of the first fast recovery diode D2; the ground terminal of the DC is connected to one end of the resistor R2, the second fast recovery diode One end of the recovery diode D3 is connected to the second end of the second power electronic switch S4; the other end of the resistor R1 is connected to the other end of the resistor R2; the second end of the first power electronic switch S1, the second fast recovery The second end of the dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com