Flux for soldering and solder paste composition

A flux and brazing technology, applied in the field of micro-printable flux, can solve the problems of inability to improve printability, undocumented, difficult to cope with high-density installation, etc., and achieve improved sliding properties, crack prevention, and crack resistance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

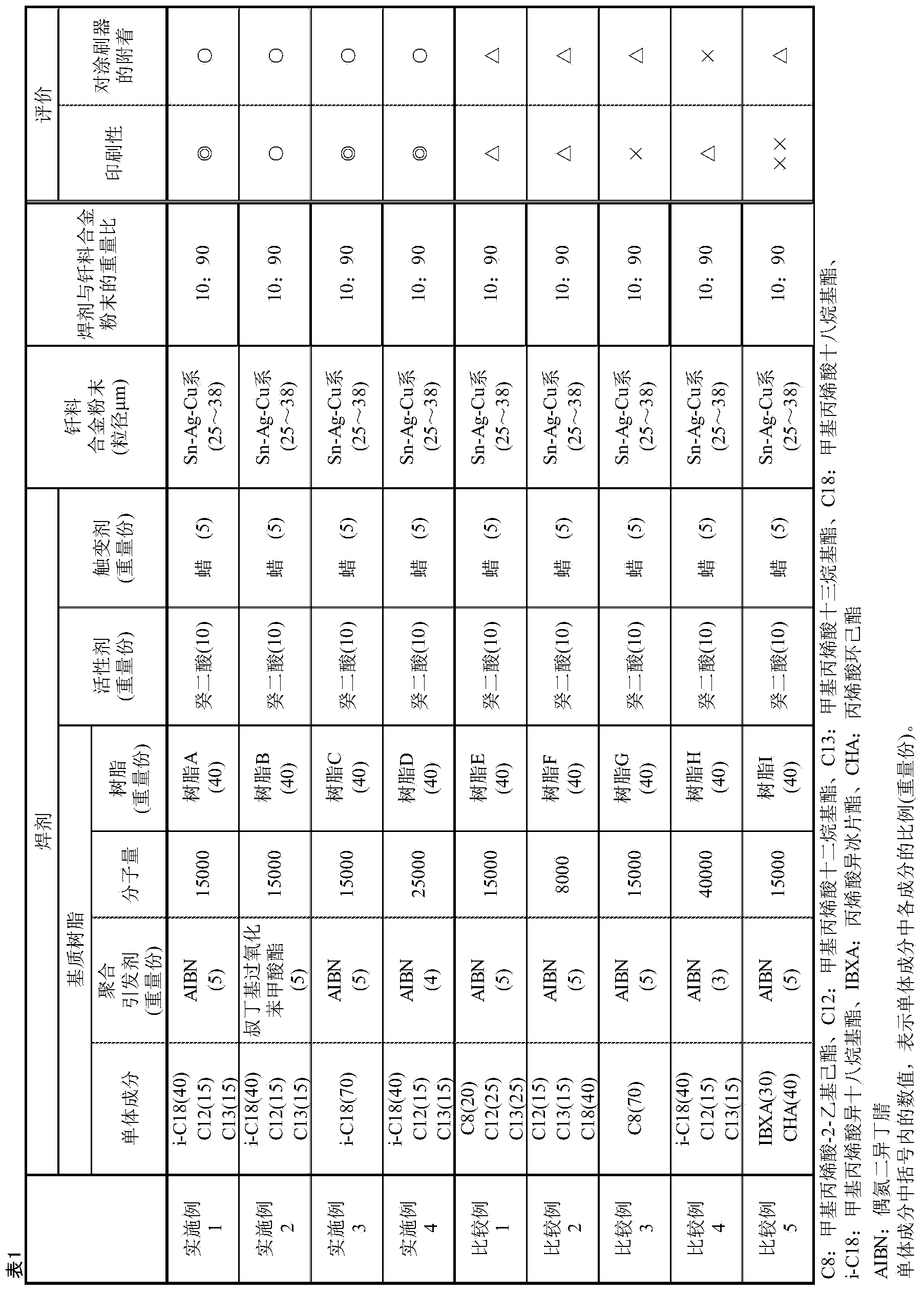

[0061] Hereinafter, an Example and a comparative example are given, and this invention is demonstrated concretely. However, the present invention is not limited to these Examples.

Synthetic example 1

[0062] (Synthesis Example 1) Synthesis of thermoplastic acrylic resin

[0063] 30 parts by weight of hexyl carbitol as a solvent was added to a reaction vessel (glass flask) equipped with a thermometer and a nitrogen gas introduction tube, and heated to 90° C. while stirring under a nitrogen atmosphere. Next, 40 parts by weight of isostearyl methacrylate (i-C18), 15 parts by weight of dodecyl methacrylate (C12), and 15 parts by weight of methacrylic acid Tridecyl ester (C13) and 5 parts by weight of azobisisobutyronitrile (AIBN) as a polymerization initiator were mixed to prepare a monomer solution. This monomer solution was dripped into the reaction container over 2 hours, and it reacted at 90 degreeC. After adding all the monomer solutions dropwise, aging was carried out at 90° C. for 2 hours to obtain a thermoplastic acrylic resin (resin A, weight average molecular weight: 15,000).

Synthetic example 2

[0064] (Synthesis example 2) Synthesis of thermoplastic acrylic resin

[0065] As a polymerization initiator, a thermoplastic acrylic resin (resin B, Weight average molecular weight: 15000).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com