Semiconductor ceramic, and positive temperature coefficient thermistor

A positive temperature coefficient, thermistor technology, applied to resistors with positive temperature coefficients, resistors, non-adjustable metal resistors, etc., to achieve the effect of excellent voltage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

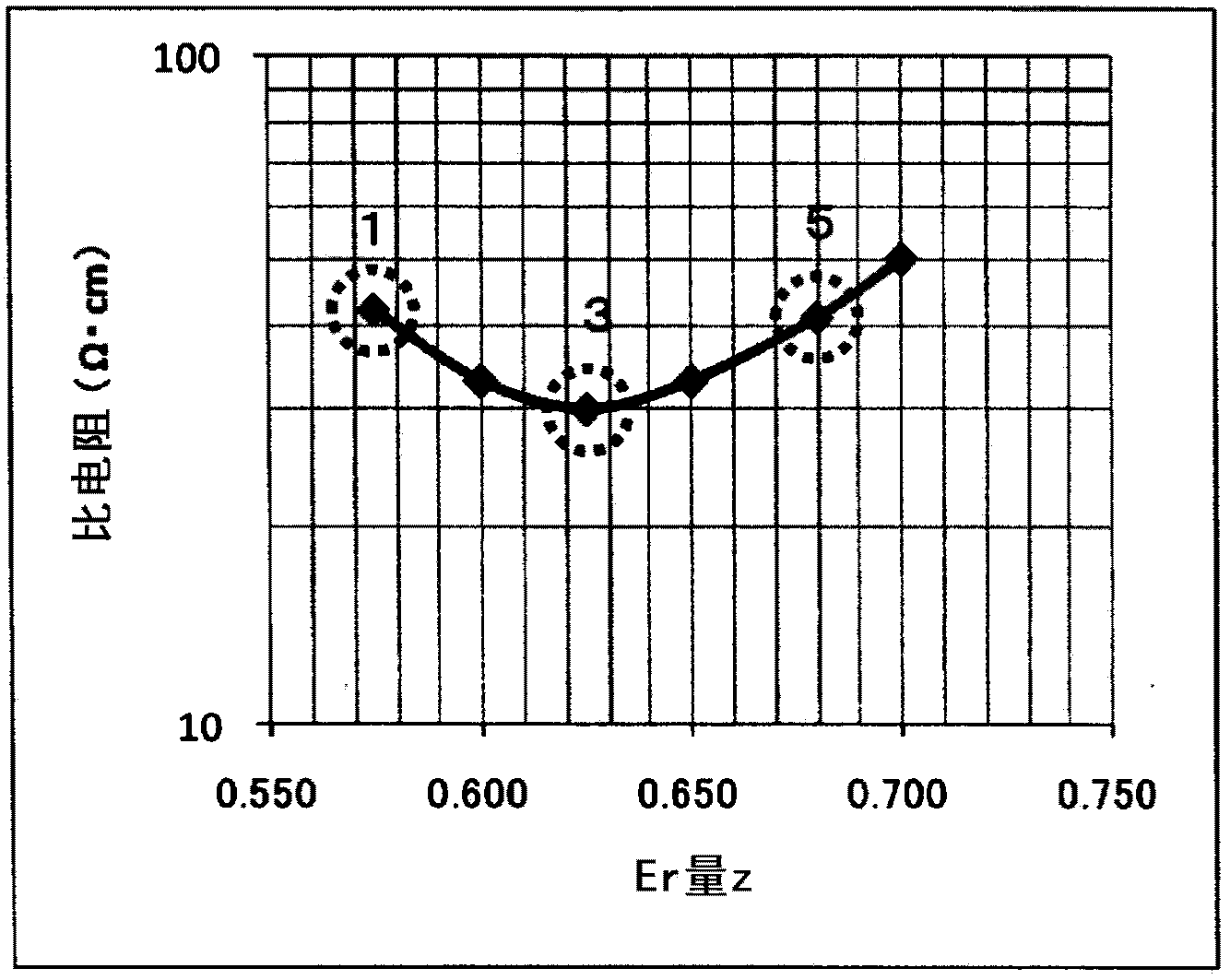

[0065] In Experimental Example 1, when Er was used as the semiconducting agent Smc, the relationship between the amount of Er and the specific resistance under predetermined x, y, and t conditions was investigated.

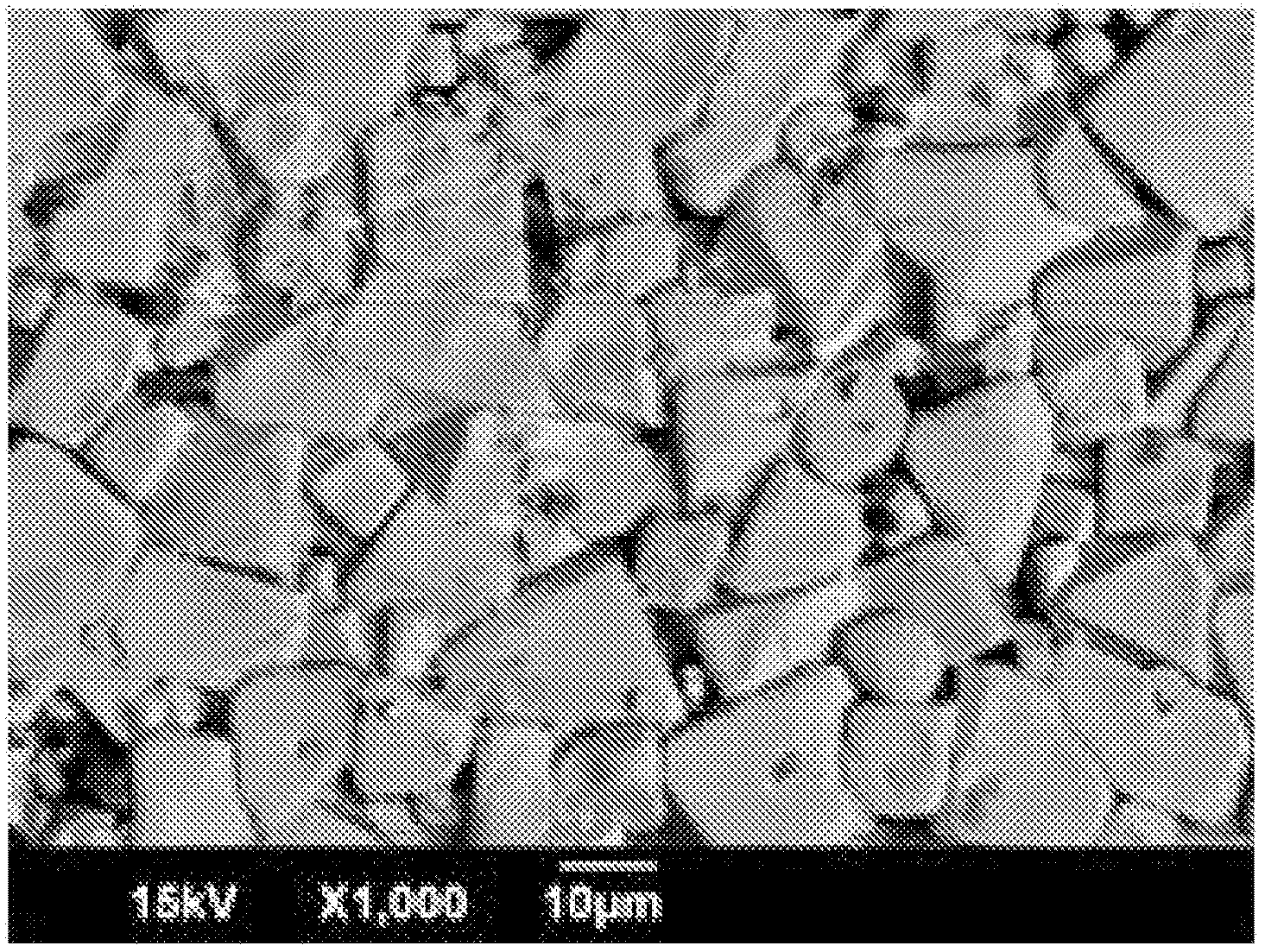

[0066] (A) Production of raw material powder for semiconductor ceramics

[0067] Initially, prepare BaCO as the parent material 3 , CaCO 3 , SrCO 3 、Er 2 o 3 , MnCO 3 and SiO 2 of each powder. Then, each matrix material was weighed and blended. Then, add pure water and polymer dispersant, and carry out wet pulverization together with PSZ balls in a ball mill for a certain period of time. Then, it was dehydrated, dried, and heat-treated at a temperature range of 1200° C. for 2 hours to obtain a raw material powder of a semiconductor ceramic represented by formula (6). The compounding ratio of each sample number is shown in Table 2 mentioned later.

[0068] Formula (6): 100(Ba 1-(x+y+z) / 100 Ca x / 100 Sr y / 100 Er z / 100 )TiO 3 +tMn

[0069] (B) Fabricat...

experiment example 2

[0083] In Experimental Example 2, Er was used as the semiconducting agent Smc, and when the values of x, y, and t were changed, the specific resistance under the conditions of each x, y, and t became extremely small. Er Quantity min . In the experiment, change the amount of Er by 0.025 to obtain z min . Table 3 shows z under the conditions of each x, y, t min value. It should be noted that the manufacturing method of the positive temperature coefficient thermistor element is the same as that of Experimental Example 1.

[0084] [table 3]

[0085]

[0086] It can be seen from Table 3 that when the amount of Ca x and the amount of Sr y increase, z min showing a decreasing trend. In addition, when the amount of Mn t increases, z min There is an increasing trend.

[0087] Next, in the order of (A) to (D), the z min formula.

[0088] Sample numbers 11 to 18 of (A) are z when the Ca amount x is changed under the conditions of y=0.000 and t=0.100 min the result of. H...

experiment example 3

[0095] In Experimental Example 3, Er was used as the semiconducting agent Smc, and the specific resistance, static withstand voltage, and resistance double point were obtained when the values of x, y, z, and t were changed respectively. The resistance double point is the temperature at which the resistance value at 25° C. is doubled.

[0096] Table 4 shows the results. As the calculated value of Er, f using the above formula (1) is described 3 The value of the computed value of (x, y, t). In addition, similarly to Experimental Example 1, the static withstand voltage lower limit value in the specific resistance of each sample is shown. The specific resistance was set to be 1000Ω·cm or less, which was practically no problem. In addition, 115-140 degreeC was set as acceptable about the resistance double point.

[0097] [Table 4]

[0098]

[0099] In sample numbers 41, 48, and 53, the Ca amount x was as small as 0.000, and the static withstand voltage value was smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com