Electrolytic copper foil for negative electrode collector of secondary battery and method for producing the same

A negative electrode current collector, electrolytic copper foil technology, applied in the direction of electrode carrier/current collector, battery electrode, electrolysis process, etc., can solve the problems of current collector damage, reduced cycle characteristics, active material layer peeling, etc., to achieve high strength , the effect of excellent extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0048] In the electrolytic cell, a titanium rotating drum with a diameter of about 3133 mm and a width of 2476.5 mm is arranged, and electrodes are arranged around the drum with an inter-electrode distance of about 5 mm. A copper concentration: 90 g / L, a sulfuric acid concentration: 80 g / L, and a gel concentration: 3 mass ppm were introduced into the electrolytic cell to prepare an electrolytic solution. Further, adjust to electrolyte temperature: 60°C, current density: 85A / dm 2 , copper was deposited on the surface of the rotating drum, the copper deposited on the surface of the rotating drum was peeled off, and an electrolytic copper foil having a thickness of 10 μm and a surface roughness Ra of 1.6 μm was continuously produced.

Embodiment 1

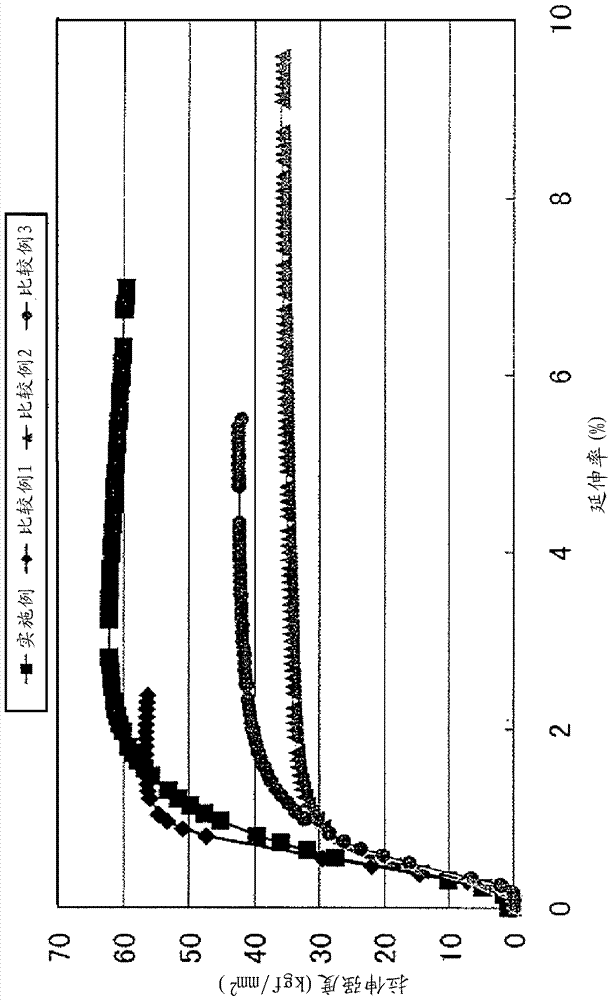

[0050] The tensile strength of embodiment 1 is 62.3kg / mm 2 , the breaking stress is 59.6kg / mm 2 , the elongation rate is 7%, and the value of tensile strength is greater than the value of breaking stress.

[0051] When the cross-section of the electrodeposited copper foil of Example 1 was observed using EBSP, there were fine particles with an aspect ratio of less than 2.0 and columnar particles with an aspect ratio of 2.0 or more. The total area of the columnar particles relative to the entire cross section was 31%. The average particle diameter of the fine particles was 0.2 μm.

[0052] For the electrodeposited copper foil of Example 1, when the tensile strength test was carried out based on IPC-TM-650 on the electrodeposited copper foil under the normal state (23°C) and after heating at 200°C for 30 minutes, respectively, after heating at 200°C for 30 minutes The tensile strength is 97% of the normal tensile strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com