Pure natural pickled vegetable curing salt and preparation method thereof

A pure natural technology for pickling salt, which is applied in the field of kimchi pickling salt and its preparation through natural crystallization under natural conditions, can solve the problems of contamination of pickled objects, health hazards of pickle eaters, etc., and shorten crystallization Evaporation time, reduce the risk of environmental pollution, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

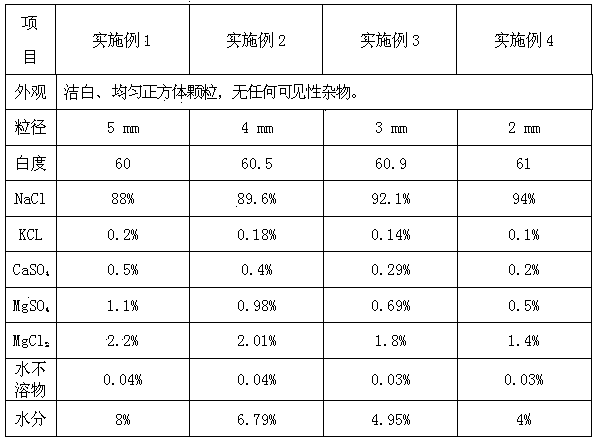

Embodiment 1

[0015] Example 1 Extract the underground brine to the evaporation pond, and carry out evaporation and concentration under natural conditions. When the concentration reaches the saturated state of sodium chloride, the concentrated solution obtained is new brine. The resulting mother liquor is used as old brine. Blend new brine and old brine at a volume ratio of 1:1 to make mixed brine, and then pour the mixed brine into the beach drying pool through a special waterway. The depth of the mixed brine in the beach drying pool is controlled at 6 cm, and it is carried out under natural conditions Evaporation and crystallization, when the salt particle size reaches about 5 mm, collect the crystallized salt in the beach drying pond, drain and pack, and then get the desired target product.

Embodiment 2

[0016] Example 2 Extract the underground brine to the evaporation pond, and carry out evaporation and concentration under natural conditions. When the concentration reaches the saturated state of sodium chloride, the concentrated solution obtained is new brine. The resulting mother liquor is used as old brine. Blend the new brine and the old brine in a volume ratio of 2:1 to form a mixed brine, and then pour the mixed brine into the beach drying pool through a special waterway. The depth of the mixed brine in the beach drying pool is controlled at 4.8 cm, and it is carried out under natural conditions. Evaporation and crystallization, when the salt particle size reaches about 4mm, collect the crystallized salt in the beach drying pond, drain and pack, and then get the desired target product.

Embodiment 3

[0017] Example 3 Extract the underground brine to the evaporation pond, and carry out evaporation and concentration under natural conditions. When the concentration reaches the saturated state of sodium chloride, the concentrated solution obtained is new brine. The resulting mother liquor is used as old brine. Blend the new brine with saturated sodium chloride concentration and the old brine at a volume ratio of 3:1 to form a mixed brine, and then pour the mixed brine into the beach drying pool through a special waterway, and the depth of the mixed brine in the beach drying pool is controlled at 3.5 cm, evaporate and crystallize under natural conditions, and when the particle size of the salt particles reaches about 3 mm, collect the crystallized salt in the beach drying pool, drain and pack, and then obtain the desired target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com