Acyclovir capsule preparation and preparation method thereof

A preparation and capsule technology, applied in the field of medicine, can solve the problems of large amount of sustained-release materials, poor release consistency, and reduce production costs, and achieve the effect of zero-order drug release, low production costs, and fewer types of excipients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

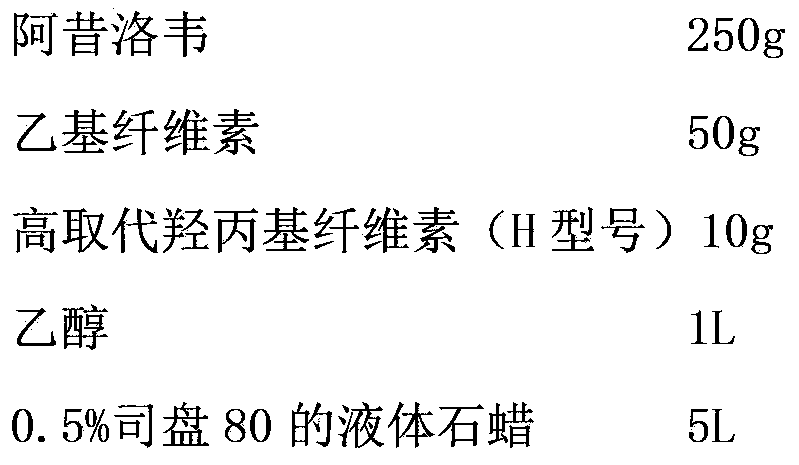

Embodiment 1

[0019]

[0020] Preparation Process:

[0021] Prescription amount Weigh acyclovir, ethyl cellulose and high-substituted hydroxypropyl cellulose, add to ethanol, stir to dissolve, add to liquid paraffin containing 0.5% (v / v) Span 80 under stirring conditions , gradually raised the temperature to 40°C, kept stirring for 6 hours, raised the temperature to 70°C, stirred for 1 hour, and filtered under reduced pressure to obtain acyclovir sustained-release pellets, which were filled into capsule shells.

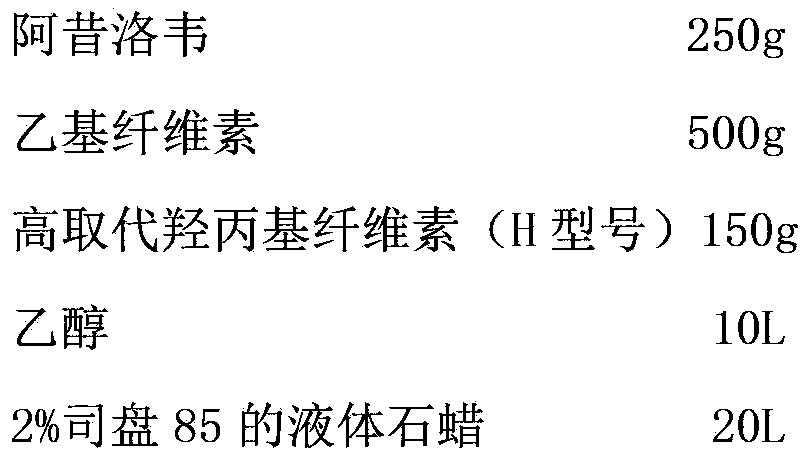

Embodiment 2

[0023]

[0024] Preparation Process:

[0025] Prescription quantity Weigh acyclovir, ethyl cellulose and high-substituted hydroxypropyl cellulose, add it to ethanol, stir to dissolve, and add it to liquid paraffin containing 2% (v / v) Span 80 under stirring conditions , gradually raised the temperature to 40°C, kept stirring for 6 hours, raised the temperature to 70°C, stirred for 1 hour, and filtered under reduced pressure to obtain acyclovir sustained-release pellets, which were filled into capsule shells.

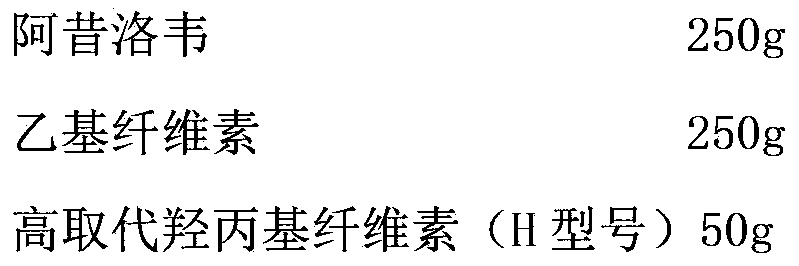

Embodiment 3

[0027]

[0028]

[0029] Preparation Process:

[0030] Prescription amount Weigh acyclovir, ethyl cellulose and high-substituted hydroxypropyl cellulose, add to ethanol, stir to dissolve, add to liquid paraffin containing 0.5% (v / v) Span 80 under stirring conditions , gradually raised the temperature to 40°C, kept stirring for 6 hours, raised the temperature to 70°C, stirred for 1 hour, and filtered under reduced pressure to obtain acyclovir sustained-release pellets, which were filled into capsule shells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com