Airflow uniform distribution type wet-method smoke desulfurization and absorption tower

A technology of wet flue gas desulfurization and absorption tower, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as uneven air distribution, increase contact area, improve utilization rate, and alleviate excessive flow velocity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

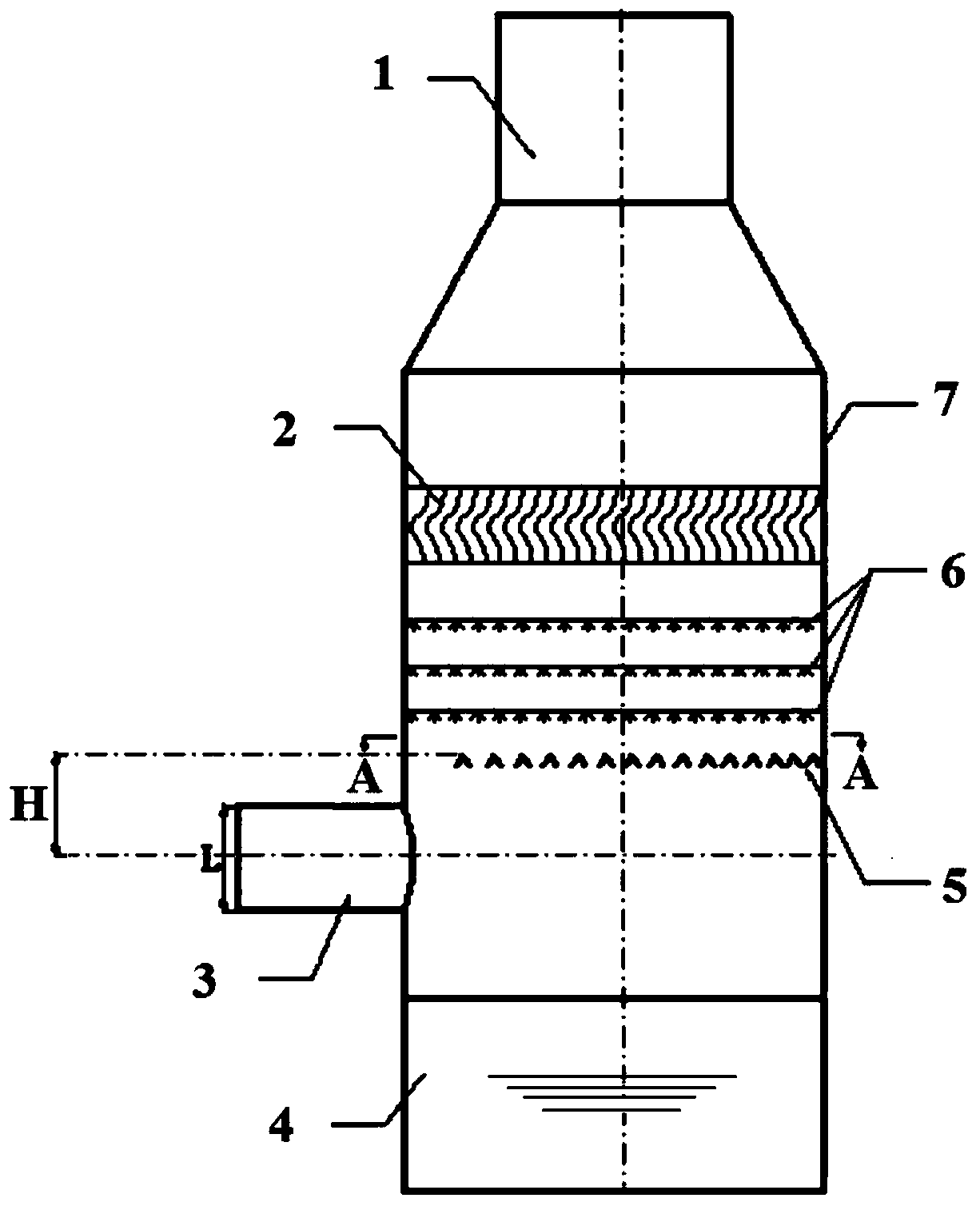

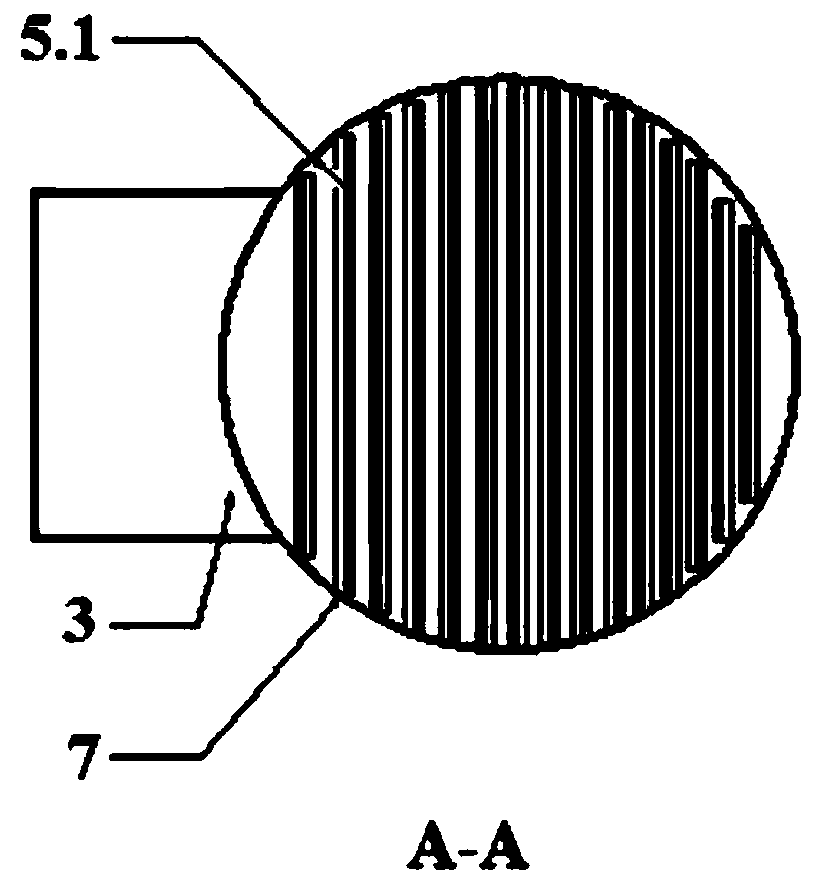

[0019] like Figure 1~2 The gas flow evenly distributed wet flue gas desulfurization absorption tower shown includes an absorption tower body 7, a slurry pool 4 is arranged at the bottom of the absorption tower body 7, and a flue gas is arranged on the wall of the absorption tower body 7 above the slurry pool 4. Gas inlet channel 3, flue gas outlet channel 1 is arranged on the top of the absorption tower body 7, and three layers of absorbent slurry spraying device 6 and demisting device are arranged in sequence from bottom to top between the flue gas inlet channel 3 and the flue gas outlet channel 1. The device 2, the absorbent slurry spraying device 6 and the flue gas inlet channel 1 are provided with an air flow uniform distribution device 5, and the air flow uniform distribution device 5 includes a plurality of horizontally spaced guide rods 5.1, and the two ends of the guide rod 5.1 It is directly connected to the cylinder wall of the absorption tower cylinder body 7 by we...

Embodiment 2

[0023] Another air-distributed wet flue gas desulfurization absorption tower of the present invention has an overall structure basically the same as that of Embodiment 1, except that the height of the guide rod 5.1 from the inverted V-shaped top angle to the bottom is 200-300mm, and the guide rod 5.1 The inverted V-shaped apex angle of the flow rod 5.1 is 60-70°, and the ratio of the total gap area between the flow guide rods 5.1 to the corresponding cross-sectional area of the absorption tower cylinder body 7 is 45%-55%.

[0024] In the present invention, an air flow uniform distribution device 5 composed of a row of inverted V-shaped guide rods 5.1 is added in the absorption tower. The effect is to re-distribute the flue gas flow in the absorption tower evenly, realize the effective rectification of the air flow in the absorption tower, significantly improve the problem of excessive local gas velocity, increase the contact area and contact time between the flue gas and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com