Electro-catalytic air purifier and air purification method thereof

An air purifier and air purification technology, applied in the field of air purification, can solve the problems of limited removal capacity, large power consumption, high cost, etc., and achieve the effect of easy dismantling, washing and reinstallation, ensuring mutual handover and flow, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

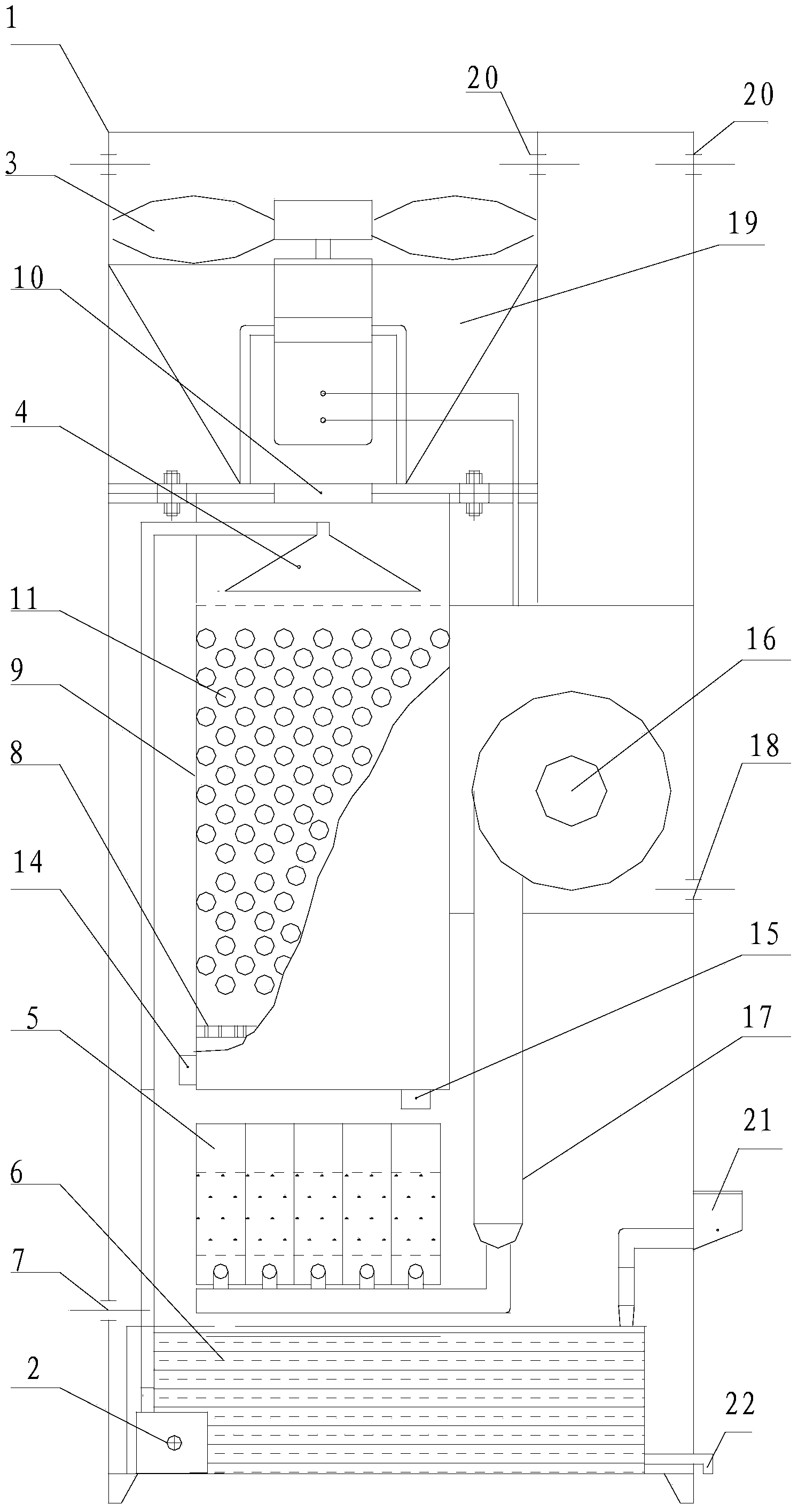

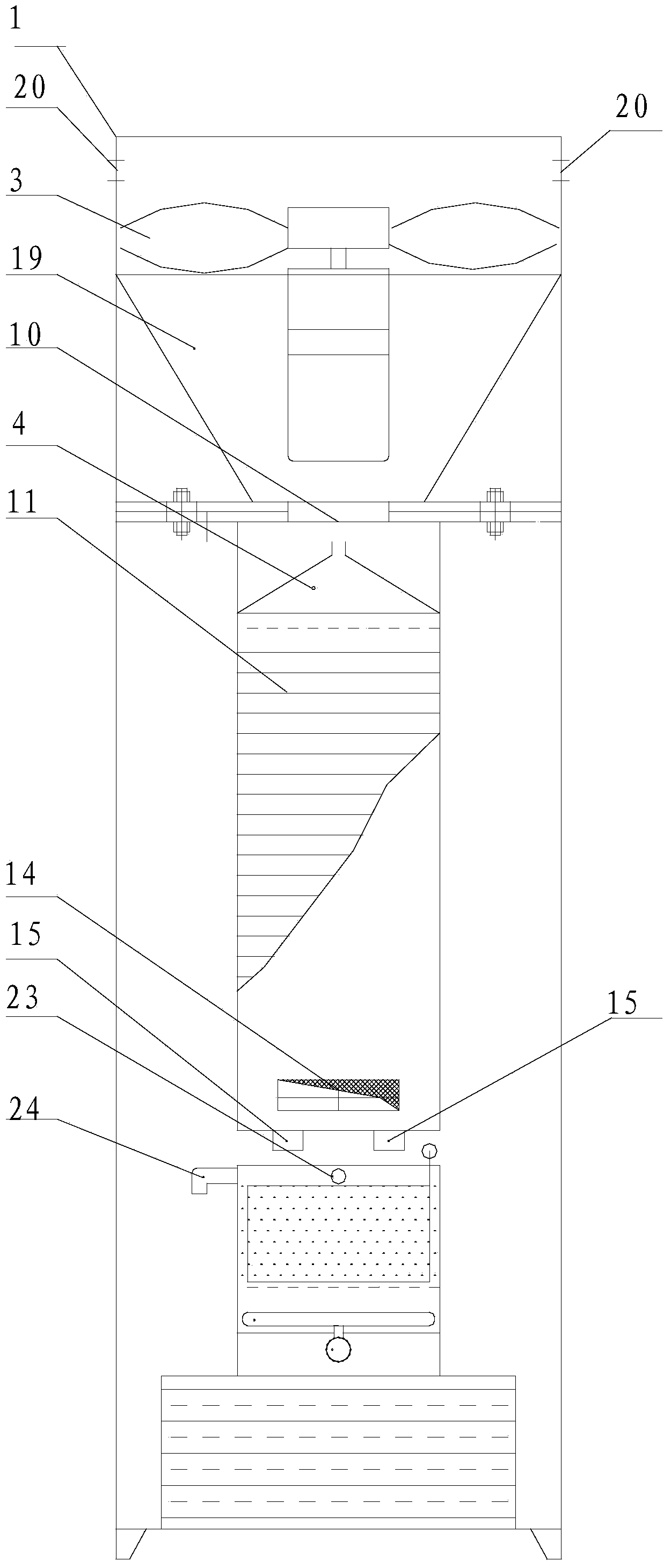

[0066] (1) Through the interaction between the exhaust fan in the air purifier and the electrolyte spray head, the formaldehyde is dissolved in a concentration of 3% Na 2 SO 4 and a concentration of 2% Na 2 CO 3 in the electrolyte;

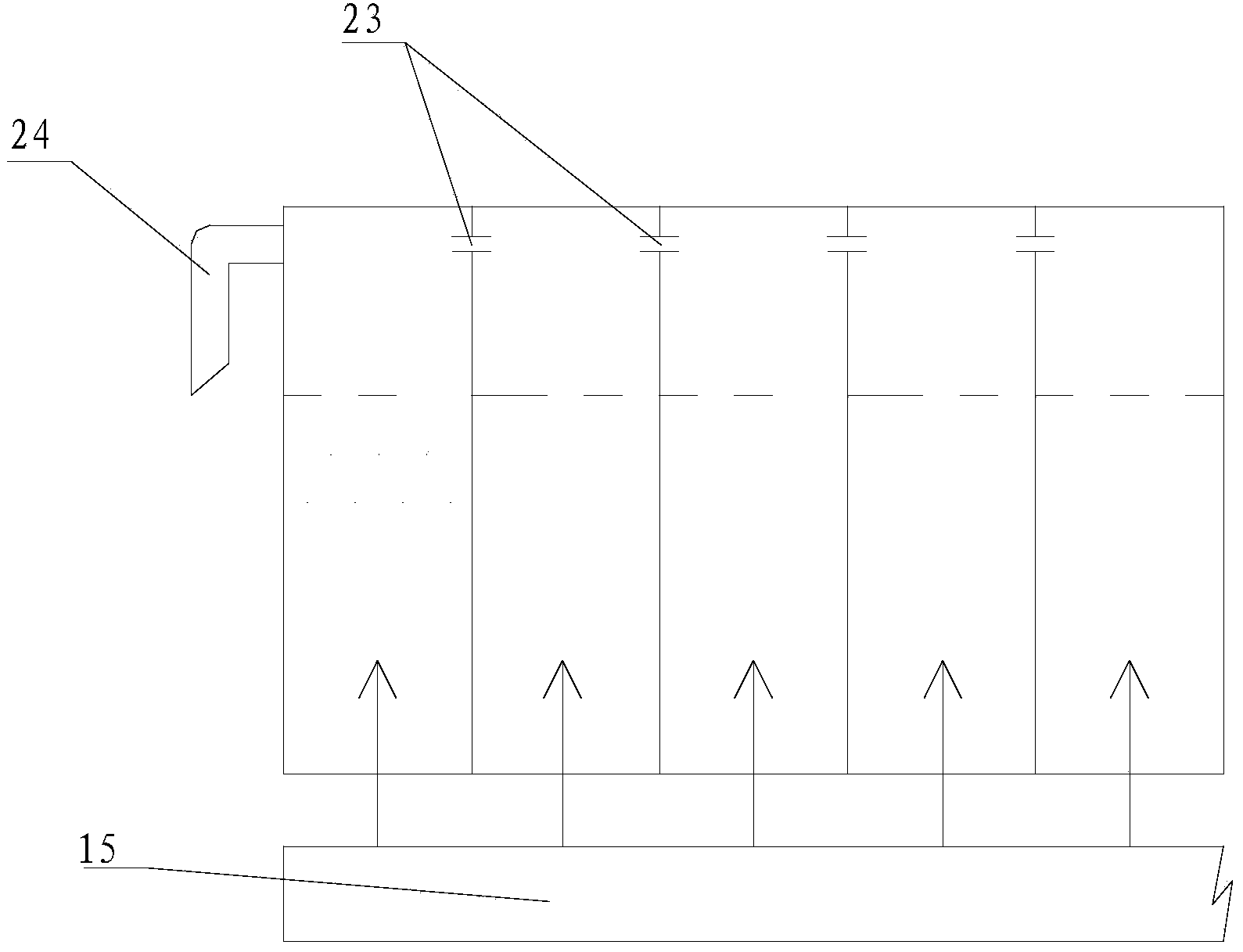

[0067] (2) The electrolyte dissolved in formaldehyde in step (1) flows vertically into the three-dimensional electrode reactor. The three-dimensional electrode reactor includes an anode plate, a cathode plate, a particle electrode and a tank body. The particle electrode is used for absorbing formaldehyde. Activated carbon particles; the anode plate is high-purity graphite, the cathode plate is stainless steel, and the activated carbon particles are surface-modified activated carbon particles with catalytic activity, and the particle size is 4mm.

[0068] (3) A 7KPa high-pressure airflow is blown from the bottom of the three-dimensional electrode reactor to turn the activated carbon particles in the reactor to form dynamic adsorption, enrich for...

example 2

[0072] (1) Through the interaction between the exhaust fan in the air purifier and the electrolyte spray head, formaldehyde is dissolved in a concentration of 5% Na 2 SO 4 and a concentration of 0.5% Na 2 CO 3 in the electrolyte;

[0073] (2) The electrolyte dissolved in formaldehyde in step (1) flows vertically into the three-dimensional electrode reactor. The three-dimensional electrode reactor includes an anode plate, a cathode plate, a particle electrode and a tank body. The particle electrode is used for absorbing formaldehyde. Activated carbon particles; the anode plate is high-purity graphite, the cathode plate is stainless steel, and the activated carbon particles are surface-modified activated carbon particles with catalytic activity, and the particle size is 5mm.

[0074] (3) A 4KPa high-pressure airflow is blown from the bottom of the three-dimensional electrode reactor to make the activated carbon particles in the reactor flip, forming dynamic adsorption, enrich...

example 3

[0078] (1) Through the interaction between the exhaust fan in the air purifier and the electrolyte spray head, the formaldehyde is dissolved in a concentration of 4% Na 2 SO 4 and a concentration of 1% Na 2 CO 3 in the electrolyte;

[0079] (2) The electrolyte dissolved in formaldehyde in step (1) flows vertically into the three-dimensional electrode reactor. The three-dimensional electrode reactor includes an anode plate, a cathode plate, a particle electrode and a tank body. The particle electrode is used for absorbing formaldehyde. Activated carbon particles; the anode plate is high-purity graphite, the cathode plate is stainless steel, and the activated carbon particles are surface-modified activated carbon particles with catalytic activity, and the particle size is 3mm.

[0080] (3) A high-pressure airflow of 1KPa is blown from the bottom of the three-dimensional electrode reactor to turn the activated carbon particles in the reactor to form dynamic adsorption, enrich ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com