Preparation method of supported transition metal catalyst utilizing iron tailings as carrier and method for degrading organic pollutants

A technology of organic pollutants and transition metals, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost and time-consuming preparation, and achieve Low cost, easy to separate, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

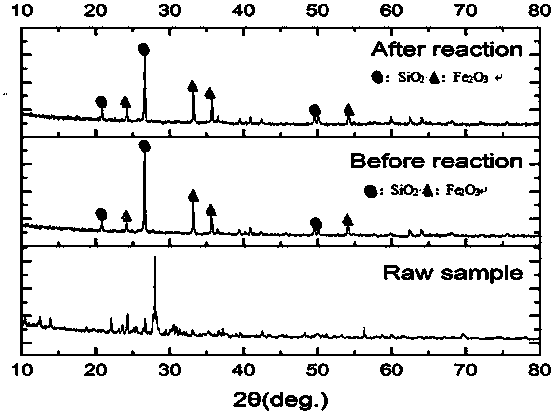

[0032] 1. Preparation of iron tailings supported cobalt catalyst

[0033] 1) Grind iron tailings to a particle size of 0.1-1.0mm, calcinate at 900°C for 6 hours, then add nitric acid solution with a mass concentration of 66%, the mass ratio of iron tailings to nitric acid solution is 2:1, and stir at room temperature for reaction 2 hours, washed to neutral and ground, then roasted at 500°C for 2 hours to obtain activated iron tailings;

[0034] 2) 3g of the activated iron tailings and cobalt acetate tetrahydrate (Co(CH 3 COO) 2 4H 2 O) Mix 0.6338g, add water to 150mL, stir magnetically at room temperature for 1 hour, add ammonia water to adjust the pH to >10, continue stirring at room temperature for 1 hour, dry and calcinate at 500°C for 2 hours to obtain a supported transition metal cobalt catalyst; The loading of Co is 5%.

[0035] 2. Degradation of organic pollutants

[0036] Weigh 20mg of the supported transition metal cobalt catalyst prepared in step 1, add the prep...

Embodiment 2

[0038] 1. Preparation of iron tailings supported cobalt catalyst

[0039] The preparation method of the supported transition metal cobalt catalyst in this example is the same as in Example 1.

[0040] 2. Degradation of organic pollutants

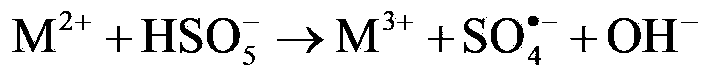

[0041] Weigh 20mg of the supported transition metal cobalt catalyst prepared in step 1, add the prepared 20mg / L methyl orange solution to simulate organic wastewater (V=200mL), and add 100mg of oxidant permonomonosulfate (PMS), at 25 ℃ under a constant temperature water bath for 2 hours, the degradation rate of organic pollutants reached 100%.

Embodiment 3

[0043] 1. Preparation of iron tailings supported cobalt catalyst

[0044] The preparation method of the supported transition metal cobalt catalyst in this example is the same as in Example 1.

[0045] 2. Degradation of organic pollutants

[0046] Weigh 20mg of the supported transition metal cobalt catalyst prepared in step 1, add the prepared 20mg / L methylene blue solution to simulate organic wastewater (V=200mL), and add 100mg of oxidant permonomonosulfate (PMS) at the same time, at 25 ℃ under a constant temperature water bath for 2 hours, the degradation rate of organic pollutants reached 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com