A screw automatic cleaner

An automatic cleaning and screw technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve problems such as increased work intensity, rapid consumption of wire wheels, and reduced local hardness of the screw, reducing labor The effect of strength, improving work efficiency, and speeding up the melting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments.

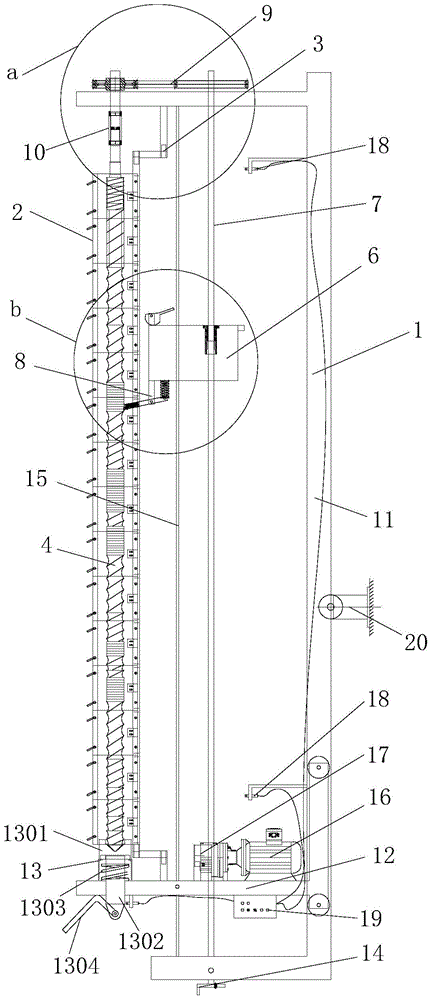

[0030] like Figure 1 to Figure 3 A screw automatic cleaner shown includes a cleaning frame 1 for clamping the screw, a heating ring 2 and a rotating bracket 3, and the heating ring 2 is installed on the cleaning frame 1 through the rotating bracket 3; when the screw 4 is clamped When cleaning the rack 1 , the heating ring 2 is passed through by the screw 4 , and the heating ring 2 covers the entire threaded portion of the screw 4 . Specifically, the heating coil 2 is formed by sequentially connecting multiple heating coil units, so that the length of the heating coil 2 can be adjusted according to the length of the screw.

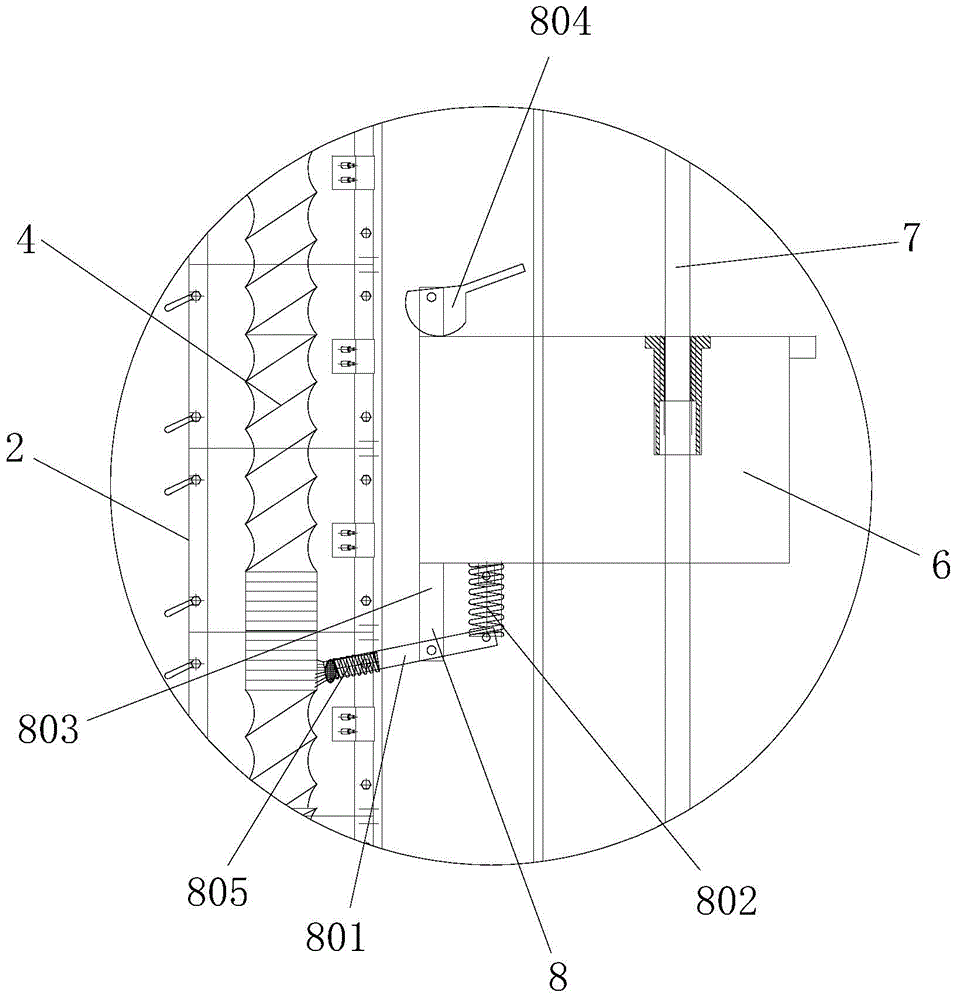

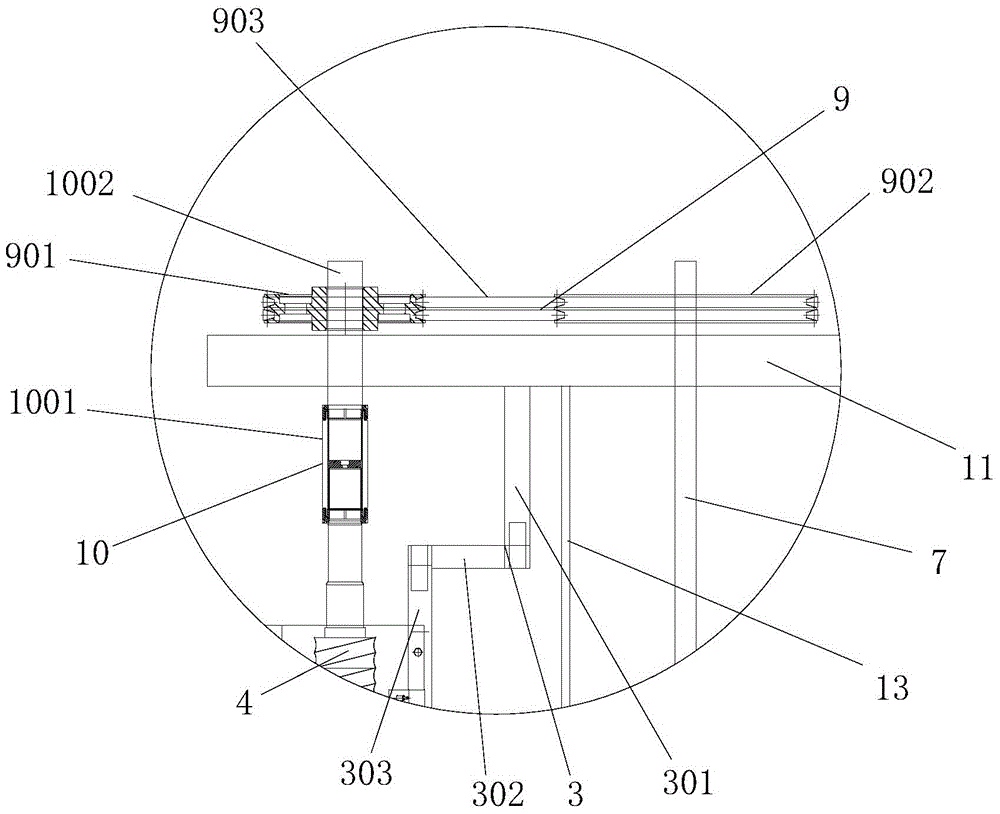

[0031] like Figure 4 and Figure 5 As shown, the heating ring 2 includes two main bodies 201 with a semicircular section, and the two main bodies 201 are connected by bolts 5; the rotating bracket 3 includes a fixed rod I301, a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com