Construction method of electric melting AZS or electro melting corundum brick crowns of full-oxygen glass melting furnace

A technology of glass melting furnace and construction method, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of inconvenient construction and single heavy, and achieve the effect of improving construction safety, large bearing capacity and ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A construction method of electric fused AZS or electric fused corundum bricks for an all-oxygen glass melting furnace, which includes:

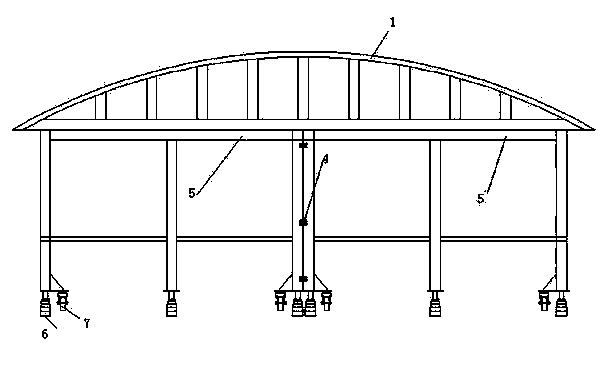

[0020] Step 1, set up the mobile arch; see figure 1 , the movable arch frame includes an arched tire frame 1, the top of which is screwed into the adjusting bolt and covers the arc plate, and placed on two mobile frames 5 connected together with bolts 4, the The bottom support of the mobile frame is supported by a jack 6, and is connected with a directional wheel 7;

[0021] Step 2: Use special steel arch tires during masonry. There are 4 adjustment screws on each brick of the steel arch tires. The screws are fixed according to the size of single and double rows. Through adjustment, the arch height reaches the assembly height and meets the requirements of the stitching line;

[0022] Step 3: According to the pre-assembly drawing, the number of each ring brick is transported to the kiln successively by hydraulic trolley from both sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com