Preparation method of wetting agent for E glass fishing rod gauze

A technology of sizing and glass, applied in the field of preparation of E glass fiber surface treatment agent, can solve the problems of resin impermeability, loss of strength of fishing rod cloth, affecting the strength of fishing rod products, etc., to reduce energy consumption, low adhesion rate, The effect of improving the quality of the fishing rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

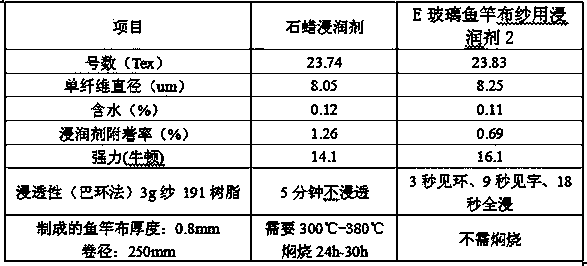

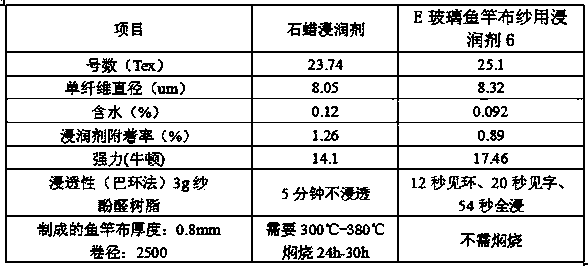

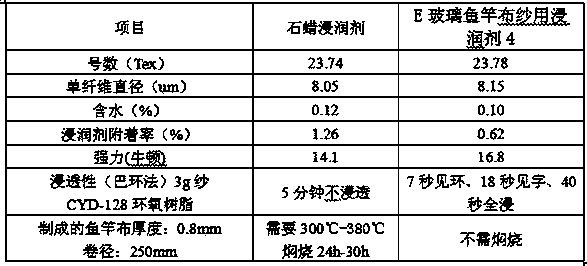

Image

Examples

Embodiment 1

[0047] a. Take 9 kg of deionized water, add 0.05 kg of citric acid to adjust the Ph value to 3-4, slowly add 0.3 kg of silane coupling agent A-174 (GE Silicones, USA) while stirring, at 60-80rpm Stir for 30-60min;

[0048] b. Mix 0.02kg of plasticizer phthalic acid and 0.4kg of emulsifier Pingpingjia-20, then heat and melt at 80-95℃, and then add 8.4kg of 70-90 evenly within 30min-60min with stirring ℃ deionized water, the stirring speed is 1000rpm-3000rpm; then cool to below 30℃;

[0049] c. Add 1 kg of 80-90°C deionized water to 0.1 kg of imidazoline cationic lubricant ZB09 (produced by Xi'an Zhongchuang Composite Materials Co., Ltd.), and stir to form a uniform transparent liquid;

[0050] d. Add 0.36 kg of 30-50°C deionized water to 0.05 kg of antistatic agent 6660A (EMERY, USA), and stir to form a uniform transparent liquid;

[0051] e. Add 5 kg of deionized water to 1.0 kg of epoxy emulsion film-forming agent YG101 (produced by Xi'an Youji Composite Materials Co., L...

Embodiment 2

[0057] a. Take 10.5 kg of deionized water, add 0.05 kg of citric acid to adjust the Ph value to 3-4, slowly add 0.35 kg of silane coupling agent A-174 (GE Silicones, USA) while stirring, at 60-80rpm Stir for 30-60min;

[0058] b. Mix 0.04 kg of plasticizer dibutyl phthalate and 0.6 kg of emulsifier Pingpingjia-20, then heat and melt at 80-95 ° C, and then add 12.8 kg of 70-90°C deionized water, the stirring speed is 1000rpm-3000rpm; then cool to below 30°C;

[0059] c. Add 2.25 kg of 80-90°C deionized water to 0.15 kg of imidazoline cationic lubricant ZB09 (produced by Xi'an Zhongchuang Composite Materials Co., Ltd.), and stir to form a uniform transparent liquid;

[0060]d. Add 0.64 kg of 30-50°C deionized water to 0.08 kg of antistatic agent 6660A (EMERY, USA), and stir to form a uniform transparent liquid;

[0061] e. Add 10 kg of deionized water to 2.0 kg of epoxy emulsion film-forming agent YG101 (produced by Xi'an Youji Composite Materials Co., Ltd.);

[0062] Add ...

Embodiment 3

[0067] a. Take 12 kg of deionized water, add 0.06 kg of citric acid to adjust the Ph value to 3-4, slowly add 0.2 kg of silane coupling agent A-174 (GE Silicones, USA) and 0.2 kg of silane coupling agent while stirring Agent A-1100 (GE Silicones, USA), stirred for 30-60min under the condition of 60-80rpm;

[0068] b. Mix 0.04kg of plasticizer dibutyl phthalate and 0.6kg of emulsifier Pingpingjia-20, then heat and melt at 80-95℃, and then add 12.8kg of 70-90°C deionized water, the stirring speed is 1000rpm-3000rpm; then cool to below 30°C;

[0069] c. Add 2.25 kg of 80-90°C deionized water to 0.15 kg of imidazoline cationic lubricant ZB09 (produced by Xi'an Zhongchuang Composite Materials Co., Ltd.), and stir to form a uniform transparent liquid;

[0070] d. Add 1 kg of 30-50°C deionized water to 0.1 kg of antistatic agent 6660A (EMERY, USA), and stir to form a uniform transparent liquid;

[0071] e. Add 12.5 kg of deionized water to 3.0 kg of epoxy emulsion film-forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com