Cement reinforcer and preparation method thereof

A technology of cement reinforcing agent and zeolite powder, applied in the field of cement additives, can solve the problem of high price, achieve the effect of improving strength, saving cement, and eliminating manual maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

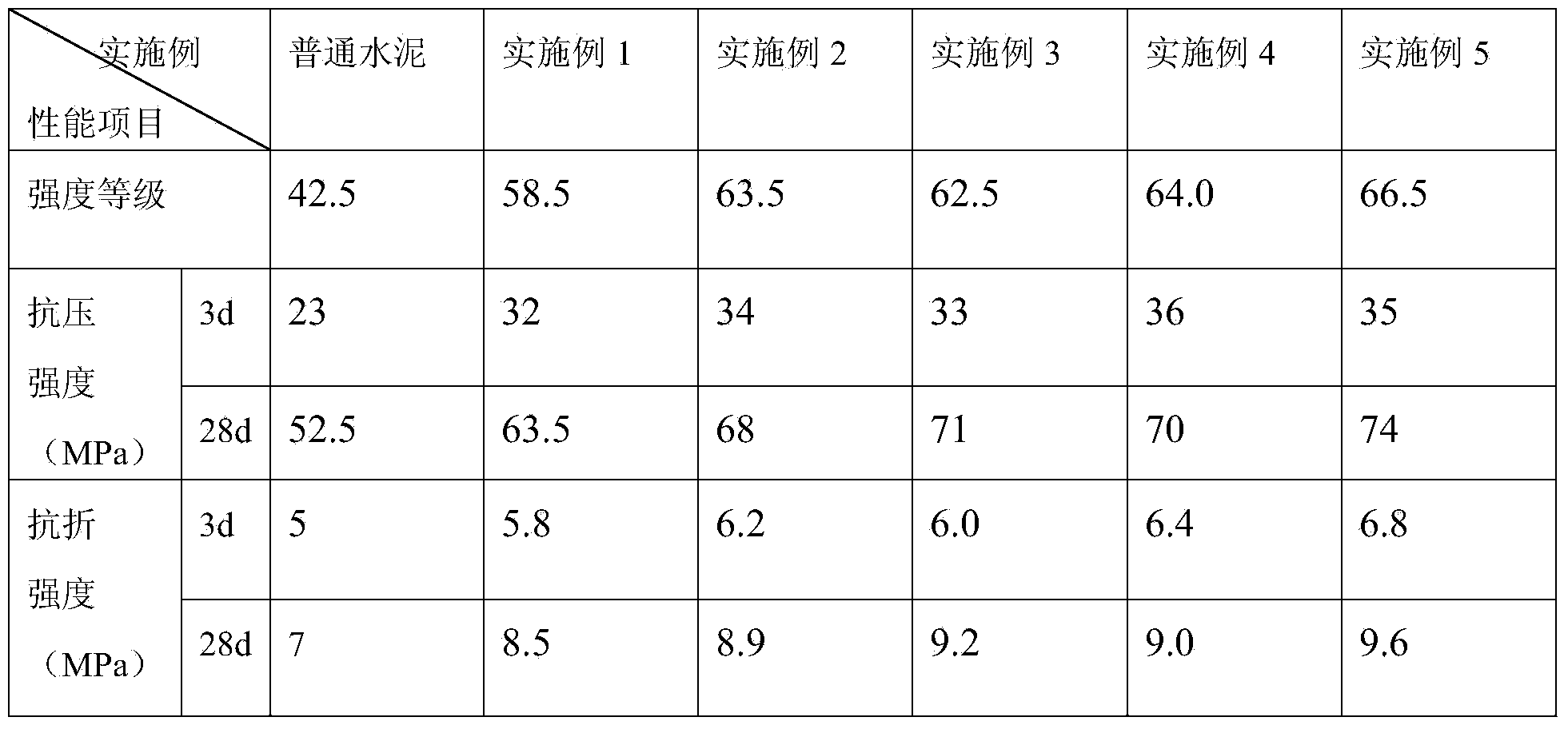

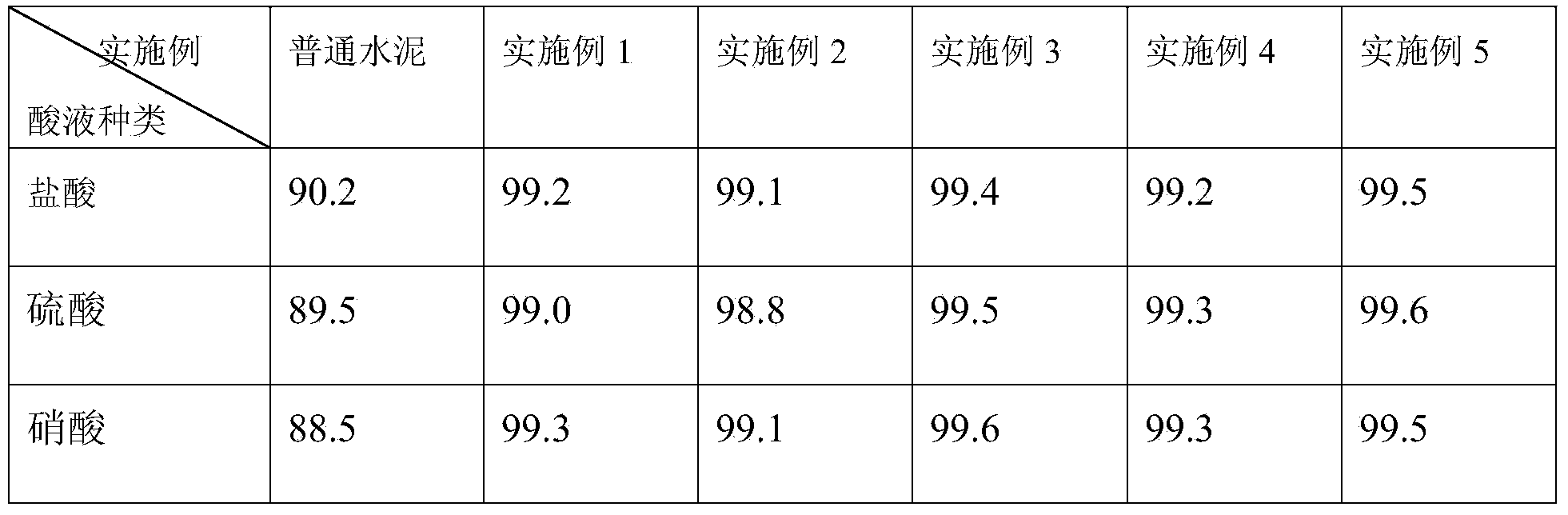

Examples

Embodiment 1

[0017] A cement reinforcing agent, its components include by weight percentage: 8 parts of zeolite powder, 22 parts of precipitated barium sulfate, 12 parts of talcum powder, 38 parts of diatomaceous earth powder, 21 parts of borax, 14 parts of acrylamide, lignosulfonic acid 21 parts of calcium, 7 parts of sodium acetate, 18 parts of ethylene glycol, 4 parts of urea, and 62 parts of water.

[0018] The preparation method of above-mentioned cement reinforcing agent, comprises the steps:

[0019] Weigh the corresponding components according to the weight of raw materials; take water and put it in a container with a stirring device, start the agitator, put sodium acetate, ethylene glycol, and urea into the container and stir for 15 minutes, then add zeolite powder, precipitated barium sulfate , talcum powder, diatomaceous earth powder, borax, acrylamide, and calcium lignosulfonate were added to the container in sequence, and stirred thoroughly for 20 minutes to obtain the finishe...

Embodiment 2

[0022] A cement reinforcing agent, its components include by weight percentage: 18 parts of zeolite powder, 15 parts of precipitated barium sulfate, 8 parts of talcum powder, 30 parts of diatomaceous earth powder, 13 parts of borax, 9 parts of acrylamide, lignosulfonic acid 9 parts of calcium, 4 parts of sodium acetate, 9 parts of ethylene glycol, 2 parts of urea, and 48 parts of water.

[0023] The preparation method of above-mentioned cement reinforcing agent, comprises the steps:

[0024] Weigh the corresponding components according to the weight of raw materials; take water and put it into a container with a stirring device, start the agitator, put sodium acetate, ethylene glycol, and urea into the container and stir for 10 minutes, then add zeolite powder, precipitated barium sulfate , talcum powder, diatomaceous earth powder, borax, acrylamide, and calcium lignosulfonate were added to the container in sequence, and stirred thoroughly for 30 minutes to obtain the finished...

Embodiment 3

[0027] A cement reinforcing agent, the components include by weight percentage: 10 parts of zeolite powder, 21 parts of precipitated barium sulfate, 10 parts of talc powder, 35 parts of diatomaceous earth powder, 19 parts of borax, 12 parts of acrylamide, calcium lignosulfonate 14 parts, sodium acetate 5 parts, ethylene glycol 16 parts, urea 4 parts, water 58 parts.

[0028] The preparation method of above-mentioned cement reinforcing agent, comprises the steps:

[0029] Weigh the corresponding components according to the weight of raw materials; take water and put it in a container with a stirring device, start the agitator, put sodium acetate, ethylene glycol, and urea into the container and stir for 15 minutes, then add zeolite powder, precipitated barium sulfate , talcum powder, diatomaceous earth powder, borax, acrylamide, and calcium lignosulfonate were added to the container in sequence, and stirred thoroughly for 25 minutes to obtain the finished product.

[0030] Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com