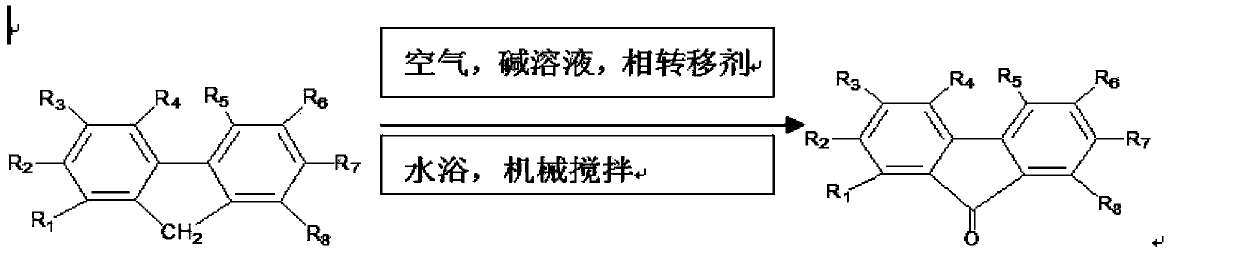

Method for preparing 9-fluorenone through using industrial fluorene

A fluorenone and industrial technology, applied in the field of organic synthesis, can solve the problems of high reaction temperature, undisclosed type of quaternary ammonium salt, difficult phase transfer catalyst effect of quaternary ammonium salt, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] ① Take 5.0g of industrial fluorene, 0.16g of reagent grade tetra-n-butylammonium chloride and 15mL of toluene, put them in a 50mL three-necked round-bottomed flask, and mechanically stir in a constant temperature water bath at 50°C until completely dissolved to obtain an oil phase;

[0049] ②Dissolve sodium hydroxide in water to prepare 10g of 30wt% aqueous phase;

[0050] ③Mix the oil phase and the water phase, mechanically stir in a constant temperature water bath at 50°C at a stirring speed of 300r / min, feed air at a speed of 200mL / min, monitor the reaction process with thin-layer chromatography, after 1.6h, thin-layer The chromatogram showed that the fluorene spot of the raw material disappeared completely, and the reaction was stopped after continuing the reaction for 0.5h to obtain the reaction solution;

[0051] ④ cooling the reaction solution, separating the water layer, reclaiming the alkali solution, taking the oil layer, washing the oil layer with water, dilu...

Embodiment 2

[0054] Except that steps 1. and 3. were changed to stirring, dissolving and reacting at 40° C., the others were the same as in Example 1. After 3.5 hours of reaction, thin-layer chromatography showed that the raw material fluorene spots completely disappeared, and the reaction was continued for 0.5 hours to stop the reaction. Obtain 4.9g product after a series of treatment of embodiment 1 step ④.

[0055] The above product was sampled for GC analysis, and the spectrum showed that there was no fluorenone component. Except for the impurities brought in by 9-fluorenone and raw material industrial fluorene, no new components appeared; after recrystallization of crude fluorenone with 5ml ethanol , sampling for GC analysis, the spectrogram shows that the content of 9-fluorenone is 100%.

Embodiment 3

[0057] Except that 0.1g of tetra-n-butylammonium chloride is replaced with 0.16 of tetra-n-butylammonium chloride in step 1., other is the same as embodiment 1. After 2.5 hours of reaction, TLC showed that the raw material fluorene spots completely disappeared, and the reaction was continued for 0.5 hours to stop the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com