2-octanone condensation-compound ethylenediamine and application thereof

A technology of octanone ethylenediamine and surfactant, which is applied in the field of mercury-substituting corrosion-inhibiting additives for alkaline zinc-nickel batteries. The effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

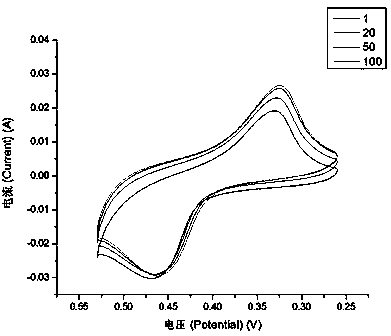

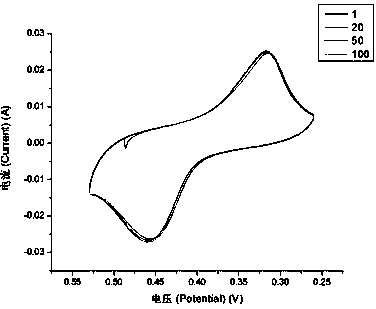

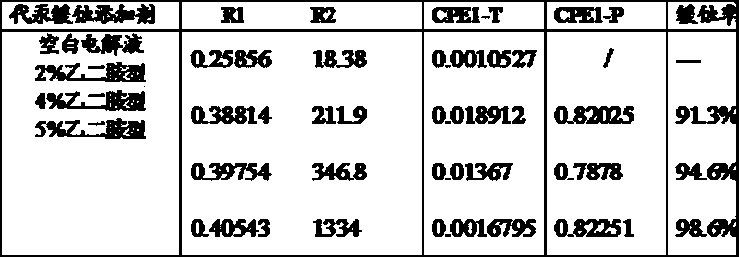

Image

Examples

Embodiment

[0012] (1) The structural formula of 2-octanone ethylenediamine:

[0013] .

[0014] (2) The preparation method of 2-octanone ethylenediamine is:

[0015] Measure 3.2 ml (20 mmol) of 2-octanone, dissolve it in 15 ml of absolute ethanol, then add it to a three-necked flask, and add 0.8 ml of ethylenediamine under a water bath at 50 °C (because ethylenediamine is easily lost by volatilization, so Make it slightly excessive), then add 1 ml of glacial acetic acid as a catalyst to start the reaction, after 3 hours of reaction, take out the three-necked flask and put it in the refrigerator to cool to 2°C, at this time, the glacial acetic acid becomes solid and precipitates, then filter to remove Remove the catalyst glacial acetic acid, and then use a rotary evaporator to evaporate the solvent anhydrous ethanol at 60°C to obtain a yellow-brown viscous substance, which is dried at 50°C to obtain a yellow-brown solid that is 2-octanone ethylenediamine.

[0016] (3) Application of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com