Plant-fiber modified partially-cured urushiol resin and preparation method and application thereof

A plant fiber and urushiol resin technology, applied in chemical instruments and methods, and other chemical processes, can solve problems affecting the ability of materials to withstand frictional heat, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

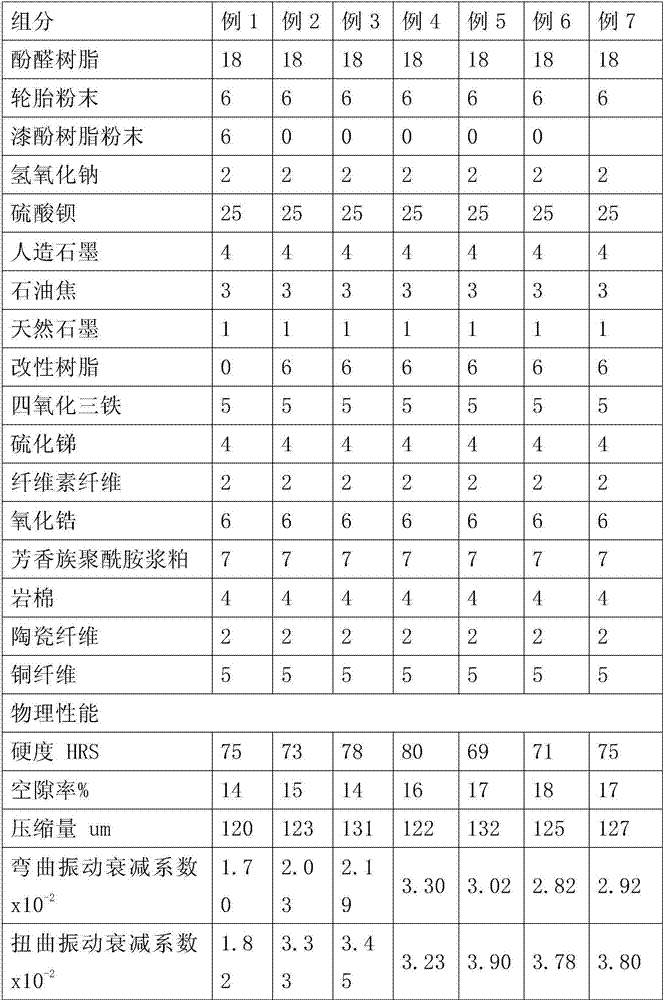

Examples

Embodiment 1

[0019] Add 5 parts of renewable plant fibers to 95 parts of melamine-modified urushiol resin prepolymer, mix well, and cure at 160°C for 1.5 hours to obtain a sample and crush it into solid particles with an average particle diameter of 100 mesh. The main properties of the modified resin are: acetone extraction rate 20%, ash content 3%, 175 ℃ volatile content 3%.

Embodiment 2

[0021] Add 90 parts of melamine-modified urushiol resin prepolymer to 10 parts of renewable plant fiber, mix well, and cure at 160°C for 1.5 hours to obtain a sample and crush it into solid particles with an average particle diameter of 100 mesh. The main properties of the modified resin are: acetone extraction rate of 15%, ash content of 3%, volatile content of 2% at 175°C.

Embodiment 3

[0023] Add 80 parts of melamine-modified urushiol resin prepolymer to 20 parts of renewable plant fibers, mix well, and cure at 160°C for 1.5 hours to obtain a sample and crush it into solid particles with an average particle size of 100 mesh. The main properties of the modified resin are: acetone extraction rate of 10%, ash content of 3%, volatile content of 175 degrees 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com