Preparation method of silk fibroin/metal nanoparticle composite system

A technology of metal nanoparticles and silk fibroin, which is applied in the field of preparation of the composite system of silk fibroin and inorganic metal nanoparticles, to achieve the effect of mature extraction technology, wide application range and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

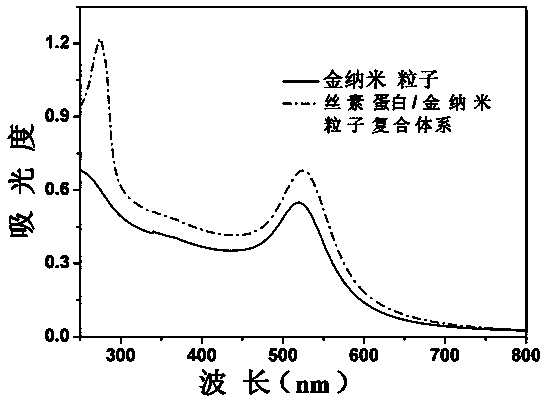

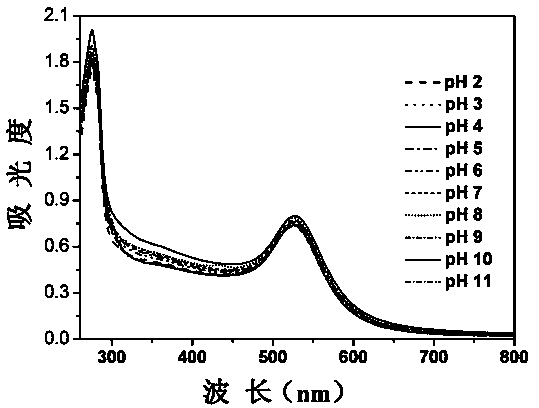

Image

Examples

Embodiment approach 1

[0024] (1) Preparation of silk fibroin aqueous solution:

[0025] Put 20 g of silkworm cocoons that had been de-pupaed and stripped into thin layers into 2 L of 0.5 wt% Na 2 CO 3 In an aqueous solution, boil for 0.5 hours to remove surface sericin, wash with deionized water three times, and dry to obtain degummed silk fibers. Use calcium chloride-ethanol-water (molar ratio 1: 2: 8) ternary system to dissolve the degummed silk fiber, the weight-to-volume ratio of the degummed silk fiber to the ternary solvent system is 10: 1, and the dissolution temperature is 60°C. The time is 3 h, and the silk fiber solution is obtained. The solution is vacuum filtered to remove impurities, and then put into a dialysis bag with a molecular weight cut-off of 8000-14000 for continuous dialysis for three days to remove salt ions to obtain a pure silk fibroin aqueous solution. Adjust the concentration of silk fibroin solution to 0.01wt%.

[0026] (2) Preparation of metal nanoparticles:

...

Embodiment approach 2

[0041] (1) Preparation of silk fibroin aqueous solution:

[0042] Put 20 g of raw silk into 1 L of 1 wt% Na 2 CO 3 in aqueous solution, boiled for 1 hour to remove surface sericin, washed three times with deionized water, and dried to obtain degummed silk fibroin fibers. The degummed silk fibers were dissolved in 9 M LiBr aqueous solution, the weight-to-volume ratio of silk fibers to LiBr aqueous solution was 10:1, the dissolution temperature was 40°C, and the dissolution time was 2 hours to obtain a silk fiber solution. Vacuum filter the silk fiber solution to remove impurities, and then put it into a dialysis bag with a molecular weight cut-off of 8000-14000 for continuous dialysis for three days to remove salt ions to obtain a pure silk fibroin aqueous solution. Adjust the concentration of silk fibroin solution to 0.05 wt%.

[0043] (2) Preparation of aqueous solution of metal nanoparticles:

[0044] In a 250 mL one-necked flask, add 100 mL of water, add 0.05 mmol Ag...

Embodiment approach 3

[0055] (1) Preparation of silk fibroin aqueous solution:

[0056] 50 g of silkworm cocoons that had been removed from the pupae and stripped into thin layers were placed in 3 L of 0.5 wt% Na 2 CO 3 In aqueous solution, boiled for 2 hours to remove surface sericin, washed three times with deionized water, and dried to obtain degummed silk fibers. Dissolve the degummed silk fibroin fibers in a ternary system of calcium chloride-ethanol-water (molar ratio 1: 2: 8), the weight-to-volume ratio of the silk fibers to the ternary solvent system is 10: 1, and the dissolution temperature is 80°C. The dissolution time was 1 h, and the silk fiber solution was obtained. The solution is vacuum filtered to remove impurities, and then put into a dialysis bag with a molecular weight cut-off of 8000-14000 for continuous dialysis for three days to remove salt ions to obtain a pure silk fibroin aqueous solution.

[0057] Adjust the concentration of silk fibroin solution to 0.15 wt%.

[0058] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com