Weak-solvent ink-jet ink for industrial piezoelectric jetting head and preparation method thereof

An inkjet ink and weak solvent technology, which is applied in the field of weak solvent inkjet ink and its preparation, can solve the problems of long transportation period, high price, and affecting the work efficiency of users, and achieve excellent smooth performance, simple preparation method, and outdoor The effect of strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

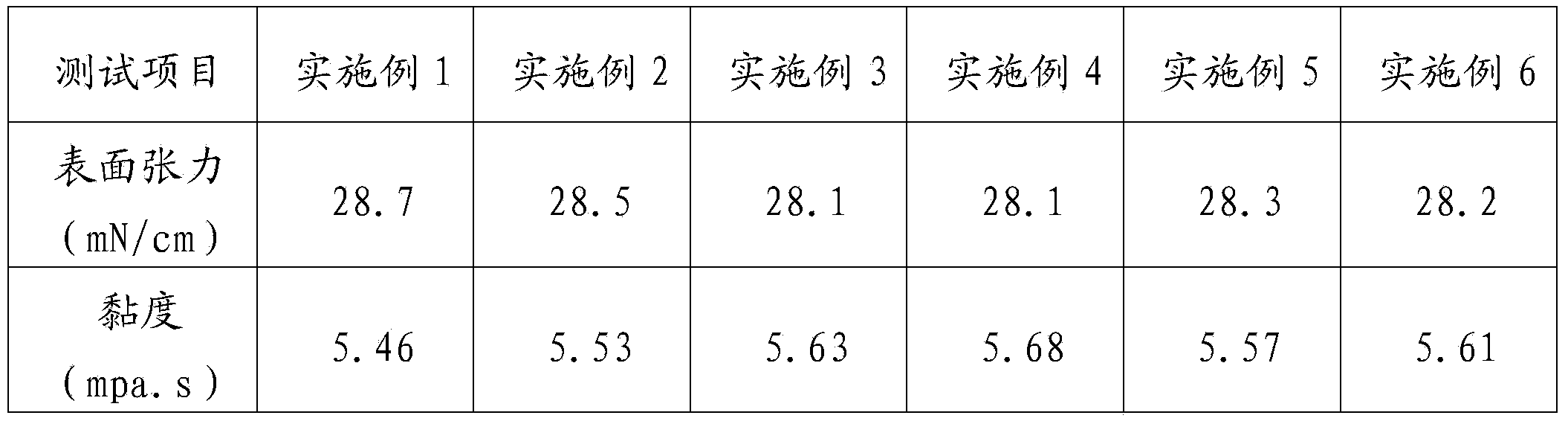

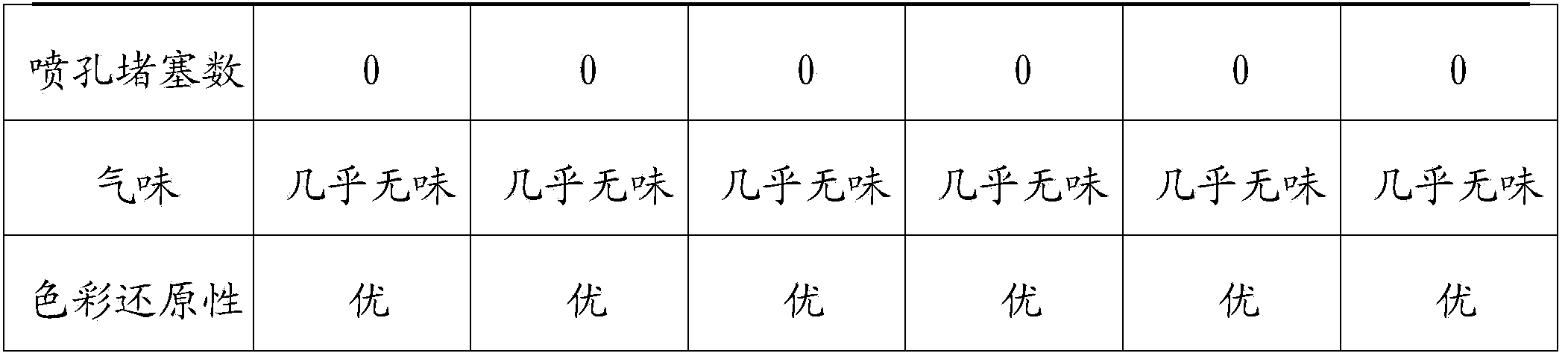

Examples

Embodiment 1

[0033] Eco-Solvent Inkjet Ink for Industrial Piezo Printheads (Red)

[0034] formula:

[0035] components

Content (weight%)

Pigment Red 122 (quinacridone pigment)

2.5

Dipropylene glycol methyl ether acetate

2

Binary vinyl resin

1.5

Modified isoparaffin

1

Butyrolactone

5

TEG0410

0.3

BYK-2001

30

acrylic

0.4

Diethylene glycol diethyl ether

58.3

[0036] Preparation:

[0037] (1) Preparation of color paste: Take Pigment Red 122 and dispersant BYK-2001 (Byk Chemicals (Tongling) Co., Ltd.) according to the above ratio, and then take 30% of the amount of wetting agent TEG0410 (Evonik Degussa (Shanghai) Co., Ltd.), 50% of the humectant dipropylene glycol methyl ether acetate consumption and 20% of the environmental protection weak solvent diethylene glycol diethyl ether consumption, mix at normal temperature, stir and disperse evenly, grind 8h, make after grinding T...

Embodiment 2

[0041] Eco-Solvent Inkjet Ink for Industrial Piezo Printheads (Blue)

[0042]formula:

[0043] components

Content (weight%)

Pigment blue 15:4 (phthalocyanine blue pigment)

5

5

Acrylic

7

Isopropanol

3

Butyrolactone

8

1.5

BYK-9131

40

acrylic

0.5

30

[0044] Preparation:

[0045] (1) Preparation of color paste: Take pigment blue 15:4 and dispersant BYK-9131 (Byk Chemicals (Tongling) Co., Ltd.) according to the above ratio, then take 30% of the amount of wetting agent methacrylate, humectant 40% of the amount of triethylene glycol and 35% of the amount of diethylene glycol, an environmentally friendly weak solvent, are mixed at room temperature, stirred and dispersed evenly, and ground for 9 hours, so that the average particle size d50 of the ground mixture is less than 150nm, and d90 is less than 250nm. , to ge...

Embodiment 3

[0048] Eco-Solvent Inkjet Ink for Industrial Piezo Printheads (Yellow)

[0049] formula:

[0050] components

Content (weight%)

Pigment Yellow PR150 (benzimidazolone pigment)

1

polyethylene glycol 400

1

Ternary vinyl resin

1

Ethylene glycol monomethyl ether

5

Butyrolactone

10

2

Solsperse32500

0.1

acrylic

0.01

79.99

[0051] Preparation:

[0052] (1) Preparation of color paste: Take Pigment Yellow PR150 and Solsperse32500 (Lubrizol Specialty Chemicals (Shanghai) Co., Ltd.) according to the above ratio, and then take 50% of the amount of wetting agent acrylate and the amount of humectant polyethylene glycol 400 50% of dipropylene glycol and 45% of the environmentally friendly weak solvent dipropylene glycol, mixed at room temperature, stirred to disperse evenly, and ground for 10 hours, so that the average particle size d50 of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com