Aqueous elastic fluorocarbon building coating covering large cracks, and preparation method and application thereof

A kind of architectural coating, water-based technology, applied in the direction of coating, etc., can solve the problem of not being able to cover cracks larger than 4mm, and achieve the effect of being suitable for industrial production, simple process, and excellent tensile strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

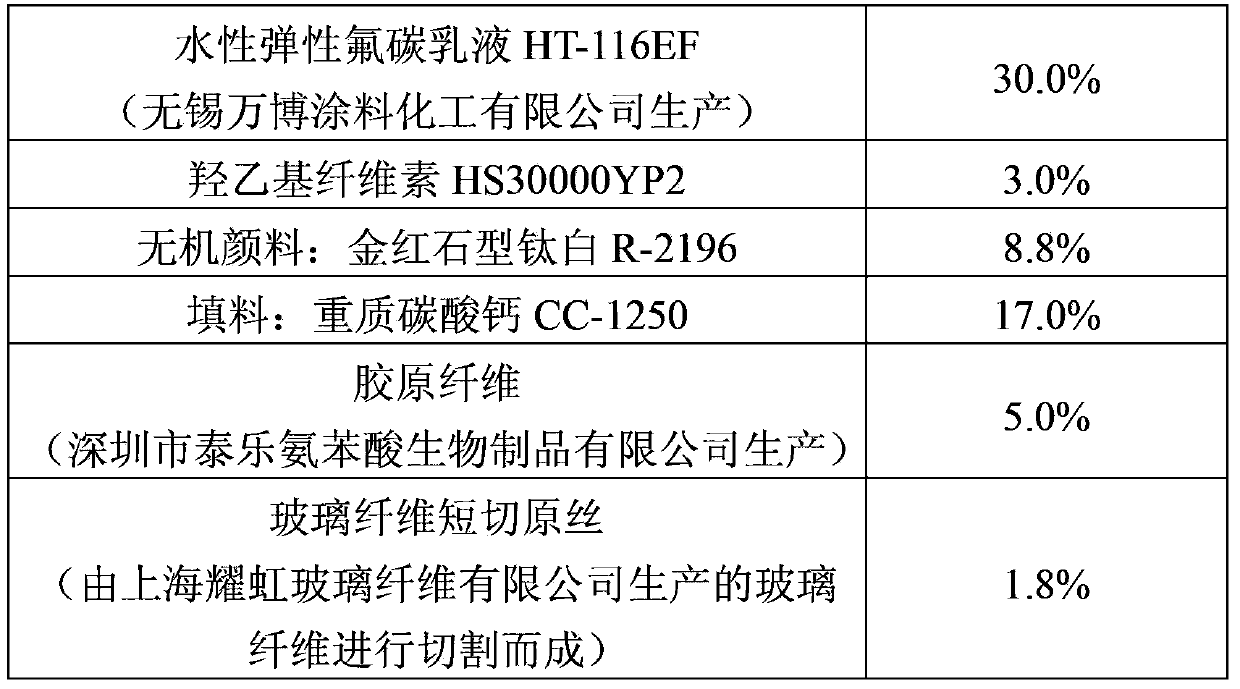

[0067] The raw material formula (wt%) of the waterborne elastic fluorocarbon architectural coating covering large cracks is shown in Table 1.

[0068] The raw material formula (wt%) of the water-based elastic fluorocarbon architectural coating covering large cracks of Table 1 Example 1

[0069]

[0070]

[0071] The preparation method of the water-based elastic fluorocarbon architectural coating covering large cracks comprises the following steps:

[0072] (1) Stir hydroxyethyl cellulose and 20.0wt% deionized water at a speed of 1200rpm, mix and dissolve to obtain solution A; mix 50.0wt% wetting and dispersing agent, 50.0wt% multifunctional additive and 30.0 Wt% defoamer and solution A were stirred at a speed of 800rpm, and mixed uniformly to obtain solution B; solution B, inorganic pigments, fillers and 50wt% deionized water were stirred at room temperature at a speed of 1500rpm, mixed evenly, and ground Until the fineness of inorganic pigments and inorganic fillers is...

Embodiment 2

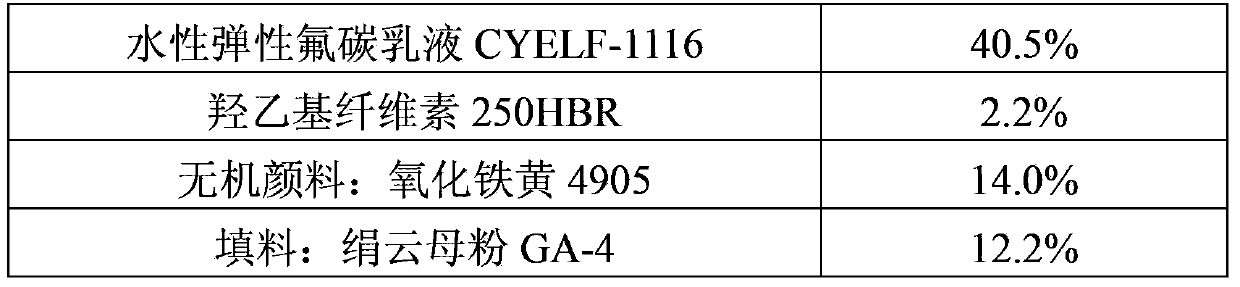

[0077] The raw material formula (wt%) of the waterborne elastic fluorocarbon architectural coating covering large cracks is shown in Table 2.

[0078] The raw material formula (wt%) of the water-based elastic fluorocarbon architectural coating covering large cracks of Table 2 Example 2

[0079]

[0080]

[0081] The preparation method of the water-based elastic fluorocarbon architectural coating covering large cracks comprises the following steps:

[0082] (1) Stir hydroxyethyl cellulose and 25.0wt% deionized water at a speed of 1100rpm, mix and dissolve to obtain solution A; mix 60.0wt% wetting and dispersing agent, 50.0wt% multifunctional additive and 30.0 Wt% defoamer and solution A were stirred at a speed of 700rpm, and mixed uniformly to obtain solution B; solution B, inorganic pigments, fillers and 40wt% deionized water were stirred at room temperature at a speed of 1400rpm, mixed evenly, and ground Until the fineness of inorganic pigments and fillers is below 45 ...

Embodiment 3

[0087] The raw material formula (wt%) of the waterborne elastic fluorocarbon architectural coating covering large cracks is shown in Table 3.

[0088] The raw material formula (wt%) of the water-based elastic fluorocarbon architectural coating covering large cracks of Table 3 Example 3

[0089]

[0090] The preparation method of the water-based elastic fluorocarbon architectural coating covering large cracks comprises the following steps:

[0091] (1) Stir hydroxyethyl cellulose and 30.0wt% deionized water at a speed of 1000rpm, mix and dissolve to obtain solution A; mix 50.0wt% wetting and dispersing agent, 30.0wt% multifunctional additive and 50.0 Wt% defoamer and solution A were stirred at a speed of 600rpm, and mixed uniformly to obtain solution B; solution B, inorganic pigments, fillers and 40wt% deionized water were stirred at room temperature at a speed of 1200rpm, mixed evenly, and ground Until the fineness of inorganic pigments and fillers is below 45 μm, slurry C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com