Modified HDPE (High-Density Polyethylene) double-wall corrugated pipe and manufacturing method thereof

A technology of double-wall corrugated pipe and manufacturing method, which is applied to rigid pipes, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of low ring rigidity and low drop impact strength, and achieves low creep rate, lightening Effect of unit weight, improved drop impact strength and ring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

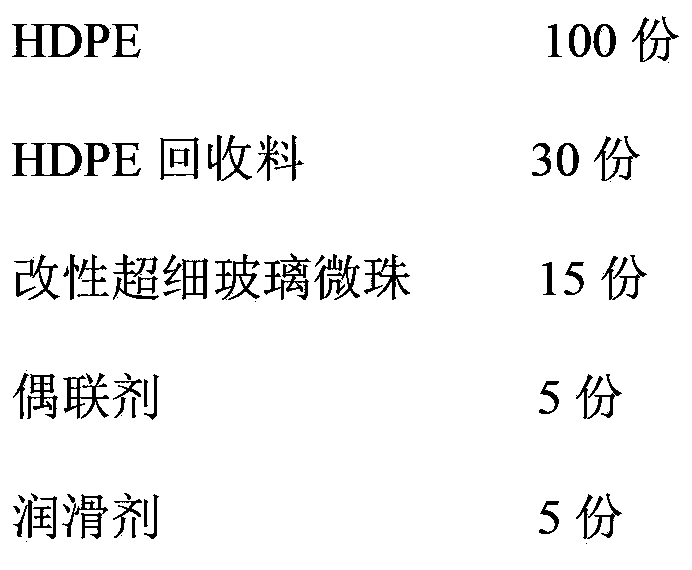

Embodiment 1

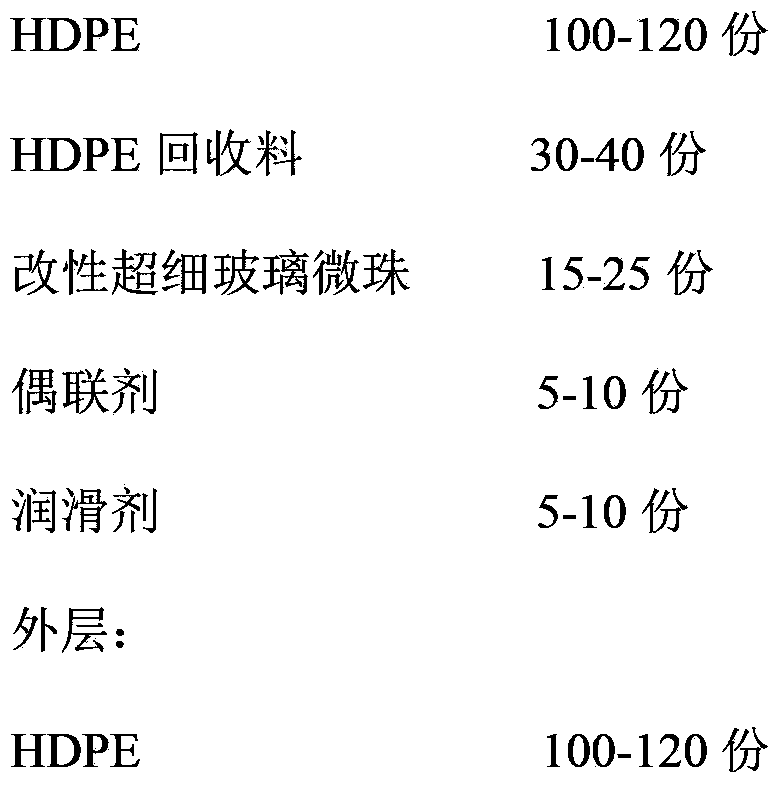

[0024] Modified HDPE double-wall corrugated pipe production materials and their mass parts are:

[0025] inner layer:

[0026]

[0027] Outer layer:

[0028] HDPE 100 parts

[0029] Modified ultrafine glass beads 15 parts

[0030] 5 parts of coupling agent

[0031] Lubricant 5 parts.

[0032] The modified ultrafine glass microspheres have a particle diameter of 3 μm. Its preparation method is:

[0033] Step 1: Dilute the ethanol solution and the silane coupling agent at a ratio of 1:3, and adjust the pH to 0.4;

[0034] Step 2: Add the dry ultrafine glass beads into the high-speed mixer, add the solution prepared in step 1 while stirring, and take it out after fully stirring for 30 minutes;

[0035] Step 3: drying at 80° C. for 3 hours to prepare the modified ultrafine glass beads.

[0036] The coupling agent is aluminate; the lubricant is paraffin.

[0037] The manufacture method of the modified HDPE double-wall corrugated pipe made according to the above formula ...

Embodiment 2

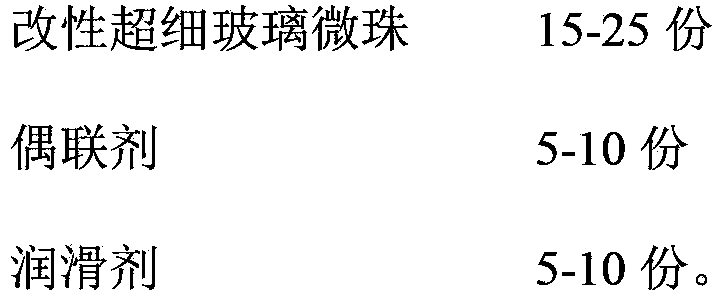

[0046] Modified HDPE double-wall corrugated pipe production materials and their mass parts are:

[0047] inner layer:

[0048]

[0049] Outer layer:

[0050] HDPE 120 parts

[0051] 25 parts of modified ultrafine glass beads

[0052] 10 parts of coupling agent

[0053] Lubricant 10 parts.

[0054] The modified ultrafine glass microspheres have a particle diameter of 7 μm. Its preparation method is:

[0055] Step 1: Dilute the ethanol solution and the silane coupling agent at a ratio of 1:3, and adjust the pH to 0.4;

[0056] Step 2: Add the dry ultrafine glass beads into the high-speed mixer, add the solution prepared in step 1 while stirring, and take it out after fully stirring for 30 minutes;

[0057] Step 3: drying at 80° C. for 3 hours to prepare the modified ultrafine glass beads.

[0058] The coupling agent is aluminate or titanate or stearic acid; the lubricant is wax.

[0059] The manufacture method of the modified HDPE double-wall corrugated pipe made acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com