Acoustic emission sensing system based on single mode fiber coupler

A single-mode optical fiber and sensing system technology, applied in the direction of material analysis using acoustic wave emission technology, can solve the problems of difficulty in wavelength detection, enhanced sensitivity, and high production cost, and achieves detection frequency bandwidth, long transmission distance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

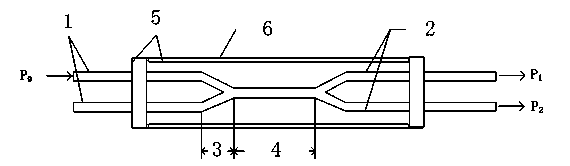

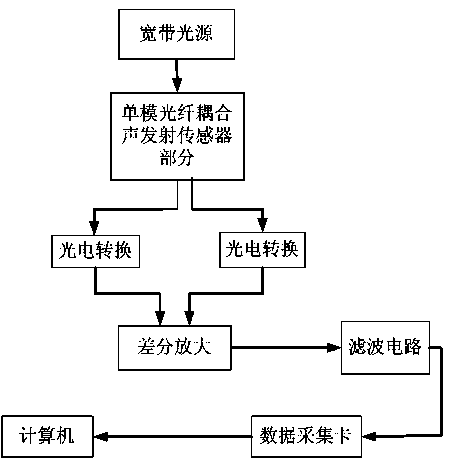

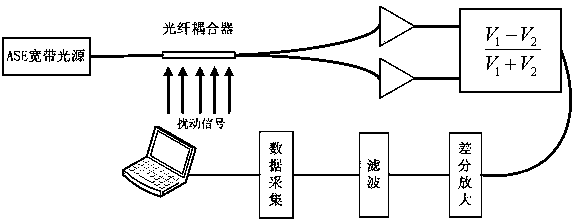

[0023] Such as figure 2 As shown, the present invention provides an acoustic emission sensing system based on a single-mode fiber coupler, including a single-mode fiber-coupled sensor part and a signal processing part, and the single-mode fiber-coupled sensor part includes: an incident optical fiber, an outgoing optical fiber, Single-mode optical fiber coupler and light source; the signal processing part includes: photoelectric conversion circuit, differential amplifier circuit, filter circuit, data acquisition card, computer; wherein the single-mode optical fiber coupler is fastened in the packaging material, and the packaging material and single-mode The fiber couplers are pasted with epoxy resin adhesive; the light emitted by the light source enters the single-mode fiber coupler through two incident fibers, and the two incident lights are output after being ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com