Intelligent roller blind machine system based on image processing technology

An image processing and rolling shutter technology, which is used in greenhouse cultivation, comprehensive factory control, climate change adaptation, etc., can solve the failure of rolling shutter machines, which cannot be judged and protected in a timely and effective manner, cannot realize growth models, and is only a dozen meters away. and other problems, to achieve the effect of intelligent fault diagnosis, intelligent protection, and reduction of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

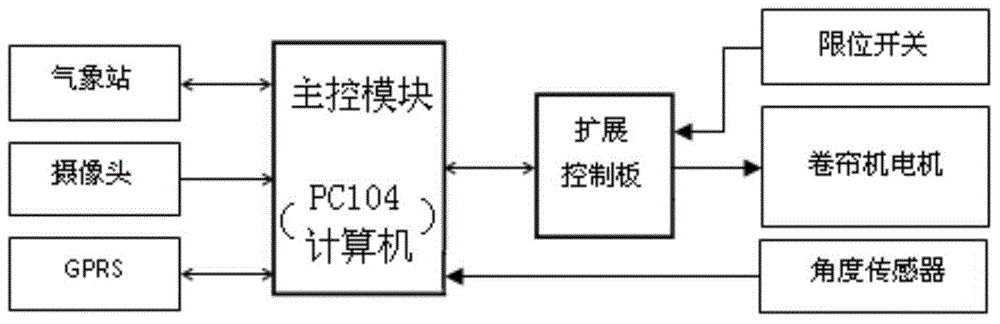

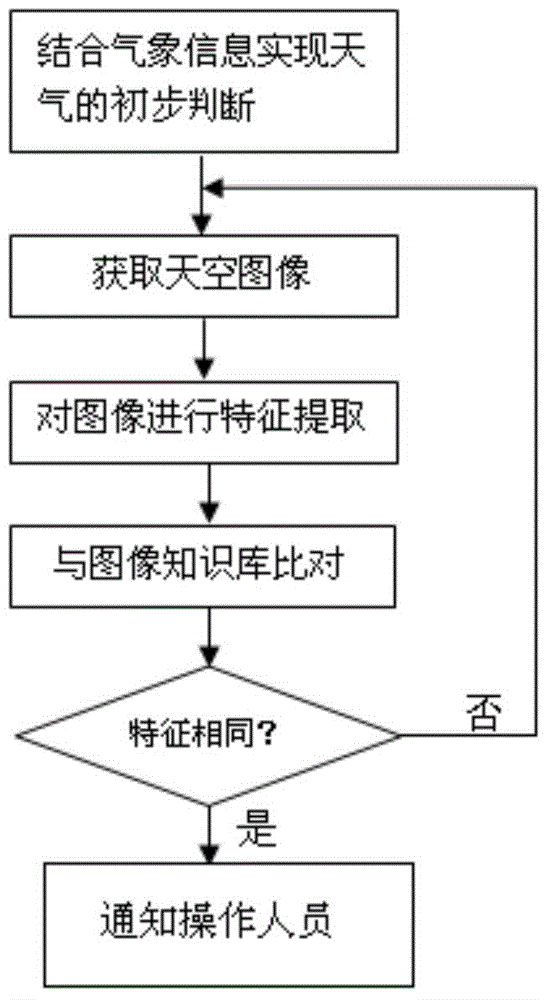

[0035] The electrical part of the system includes a main control module, a weather station, a camera, a GPRS module, an extended control board, a limit switch and a shutter motor; the peripheral equipment is a greenhouse. The main control module in this embodiment adopts a PC104 computer, and the main control module is a data processing platform and a control platform. The PC104 computer in this embodiment adopts a touch screen visual operation mode. Both the weather station and the camera are connected to the main control module, and send the collected information to the main control module in real time; the GPRS module is connected to the main control module through a serial interface (or directly integrated in the main control module), and the main control module is The module can send the meteorological information outside the greenhouse and the location information of the heat preservation quilt to the operator in the form of MMS (text and image), so that the operator can ...

Embodiment 2

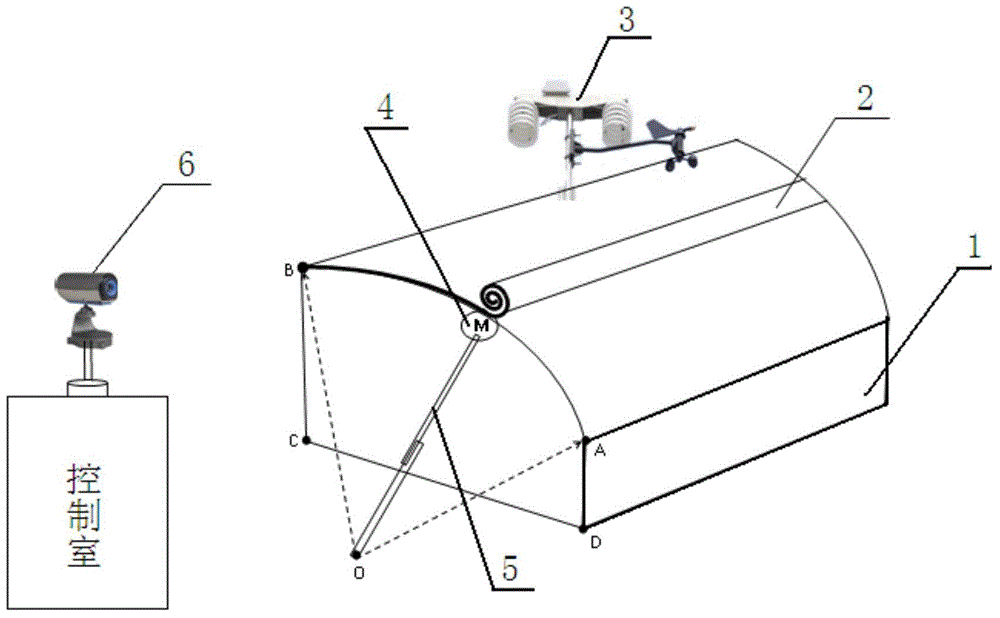

[0052] In order to make the fault diagnosis process intelligent, the system can still complete the fault diagnosis when the operator is not in the control room; and ensure that the camera can continue to monitor the safety of the greenhouse or collect sky images during the operation of the insulation quilt. In this embodiment, an angle sensor 7 is added to the system described in Embodiment 1, and the angle sensor 7 is used for precise positioning of the heat preservation quilt and intelligent fault diagnosis for the shutter machine. The angle sensor communicates with the main control module through RS485 serial mode, and the electrical connection is as follows: figure 1 shown.

[0053] The angle sensor 7 is installed on the bottom of the swing rod. In order to ensure that the measurement result of the angle sensor 7 is accurate and not affected by the swing of the swing rod 5, the angle sensor is adopted in this embodiment. Figure 4 installation shown. The installation str...

Embodiment 3

[0057] Precise positioning of the heat preservation quilt and intelligent fault diagnosis of the shutter machine through the rope displacement sensor. In the system described in Embodiment 1, a stay rope displacement sensor is added. The stay rope displacement sensor is fixed on figure 2 At point A in the figure, the rope end of the rope displacement sensor is fixed on the roller shutter motor, and the information output terminal communicates with the main control module through RS485 serial mode.

[0058] The principle of precise positioning of the thermal insulation quilt by the drawstring displacement sensor is: after the operator makes a decision to roll up or lay the thermal insulation quilt, he presets the position where the thermal insulation quilt needs to be laid in the main control module. In the process of rolling up or laying the heat preservation quilt, the roller shutter machine and the heat preservation quilt move together, which will drive the stretching move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com