Industrial production line of insect protein and technology for producing insect protein

An insect protein and production line technology, applied in animal husbandry, application, animal feed, etc., can solve problems such as complex steps, high labor intensity of workers, and long production cycle, so as to improve production efficiency, shorten production cycle, and save input costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

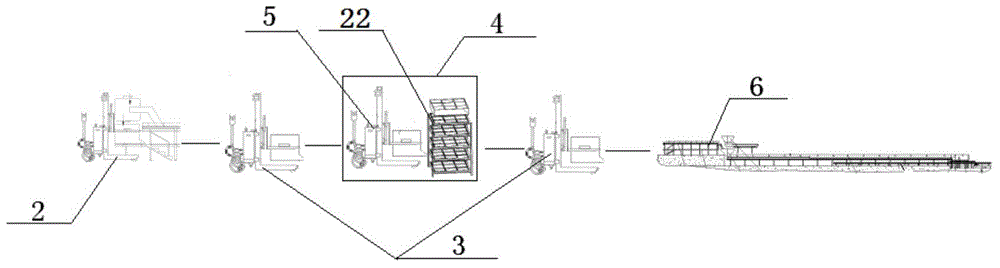

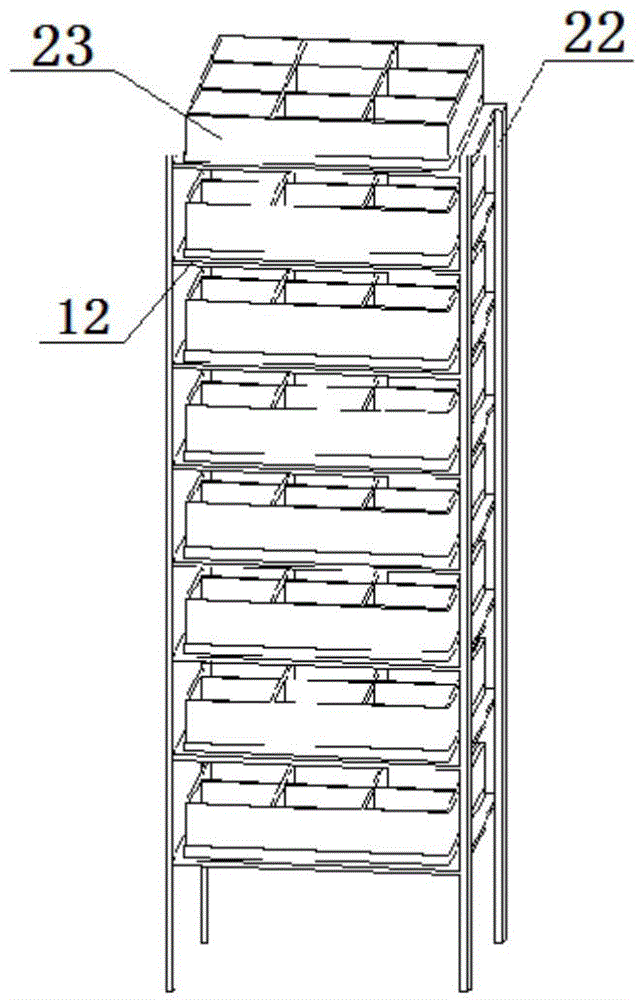

[0032] Embodiment 1 of the present invention: as figure 1 As shown, an insect protein industrial production line includes a charging system 2, a training room 4 and a separation system 6, and the charging system 2 and the training room 4 are connected to the training room 4 through an electric stacker 3 with a hopper 16, The training room 4 is provided with a feeding device 5 and a storage rack 22 , and the training room 4 is connected to the separation system 6 through an electric stacker 3 with a hopper 16 .

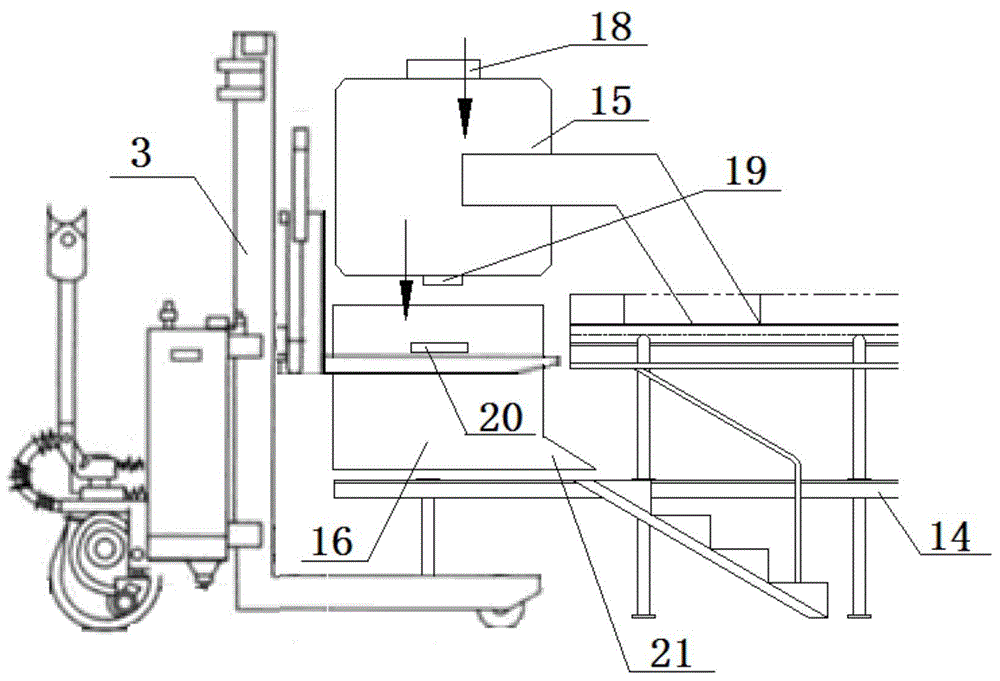

[0033] Such as figure 2 As shown, the charging system 2 includes a material receiving platform 14 and a mixer 15, the mixer 15 is located on the material receiving platform 14, the top of the mixer 15 is provided with a bottom material inlet 18, and the bottom of the mixer 15 is provided with a bottom material outlet 19, a hopper 16 A fixing device 20 is provided on the outer wall of the hopper, and the hopper 16 is fixed on the fork pole of the electric stacker 3 th...

Embodiment 2

[0044] Embodiment 2 of the present invention: as figure 1 As shown, an insect protein industrial production line includes a charging system 2, a training room 4 and a separation system 6, and the charging system 2 and the training room 4 are connected to the training room 4 through an electric stacker 3 with a hopper 16, The training room 4 is provided with a feeding device 5 and a storage rack 22 , and the training room 4 is connected to the separation system 6 through an electric stacker 3 with a hopper 16 .

[0045] Such as figure 2 As shown, the charging system 2 includes a material receiving platform 14 and a mixer 15, the mixer 15 is located on the material receiving platform 14, the top of the mixer 15 is provided with a bottom material inlet 18, and the bottom of the mixer 15 is provided with a bottom material outlet 19, a hopper 16 A fixing device 20 is provided on the outer wall of the hopper, and the hopper 16 is fixed on the fork pole of the electric stacker 3 th...

Embodiment 3

[0056] Embodiment 3 of the present invention: as figure 1 As shown, an insect protein industrial production line includes a charging system 2, a training room 4 and a separation system 6, and the charging system 2 and the training room 4 are connected to the training room 4 through an electric stacker 3 with a hopper 16, The training room 4 is provided with a feeding device 5 and a storage rack 22 , and the training room 4 is connected to the separation system 6 through an electric stacker 3 with a hopper 16 .

[0057] Such as figure 2 As shown, the charging system 2 includes a material receiving platform 14 and a mixer 15, the mixer 15 is located on the material receiving platform 14, the top of the mixer 15 is provided with a bottom material inlet 18, and the bottom of the mixer 15 is provided with a bottom material outlet 19, a hopper 16 A fixing device 20 is provided on the outer wall of the hopper, and the hopper 16 is fixed on the fork pole of the electric stacker 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com