High-concentration printing ink waste water processing technology

A printing ink and waste water treatment technology, applied in the field of printing, can solve the problems of high investment cost, complicated management and long process flow of ton water project, and achieve the effect of low operating cost, simplified operation management, and low engineering investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments.

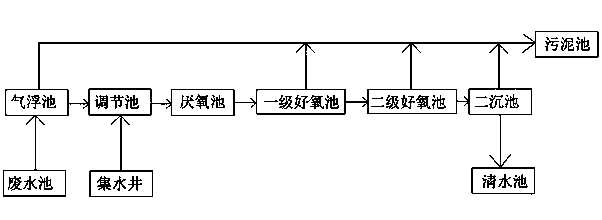

[0024] like figure 1 , a high-concentration printing ink wastewater treatment process, is characterized in that, comprises the following steps:

[0025] (1) The ink waste water discharged from the workshop is introduced into the water collection well through the original pipeline after the sundries and large pieces of garbage are removed by the grids of each discharge outlet. Here, the volume and quality of the waste water are preliminarily adjusted by air agitation to make it uniform.

[0026] (2) Pump the thoroughly mixed wastewater to the coagulation reaction tank quantitatively, add dilute sulfuric acid with a concentration of 50% to the wastewater, the dosage is 10g / L, start the air stirring for 3.0min, and then add the coagulant PAC, The amount of solid PAC added is 10g / t. Under the action of coagulant PAC, granular and colloidal pollutants in wastewater a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com