Wet chopped strand immersion agent and preparation method thereof

A technology of chopped shreds and sizing, applied in the chemical industry, can solve problems such as quality claims, product appearance defects, and unqualified felt surface appearance quality, and achieve the effects of increasing sales, good dispersion performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] This example is a wet-laid chopped strand sizing.

[0014] The wet chopped strand sizing agent includes 0.2-0.4% acetic acid, 0.5-0.6% coupling agent, 0.02-0.10% cellulose ether, 0.01-0.08% dispersant, 0.01-0.03% lubricant And 0.002-0.008% preservative, the balance is deionized water, the total amount is 100%. The stated percentages are all percentages by weight.

[0015] The coupling agent is KH-560 or KH-570, the cellulose ether is hydroxypropylmethylcellulose or hydroxyethylcellulose, the dispersant is aliphatic carboxylic acid DSC-1, and the lubricant is fatty acid amide CQ-304. The preservative is 40% formalin.

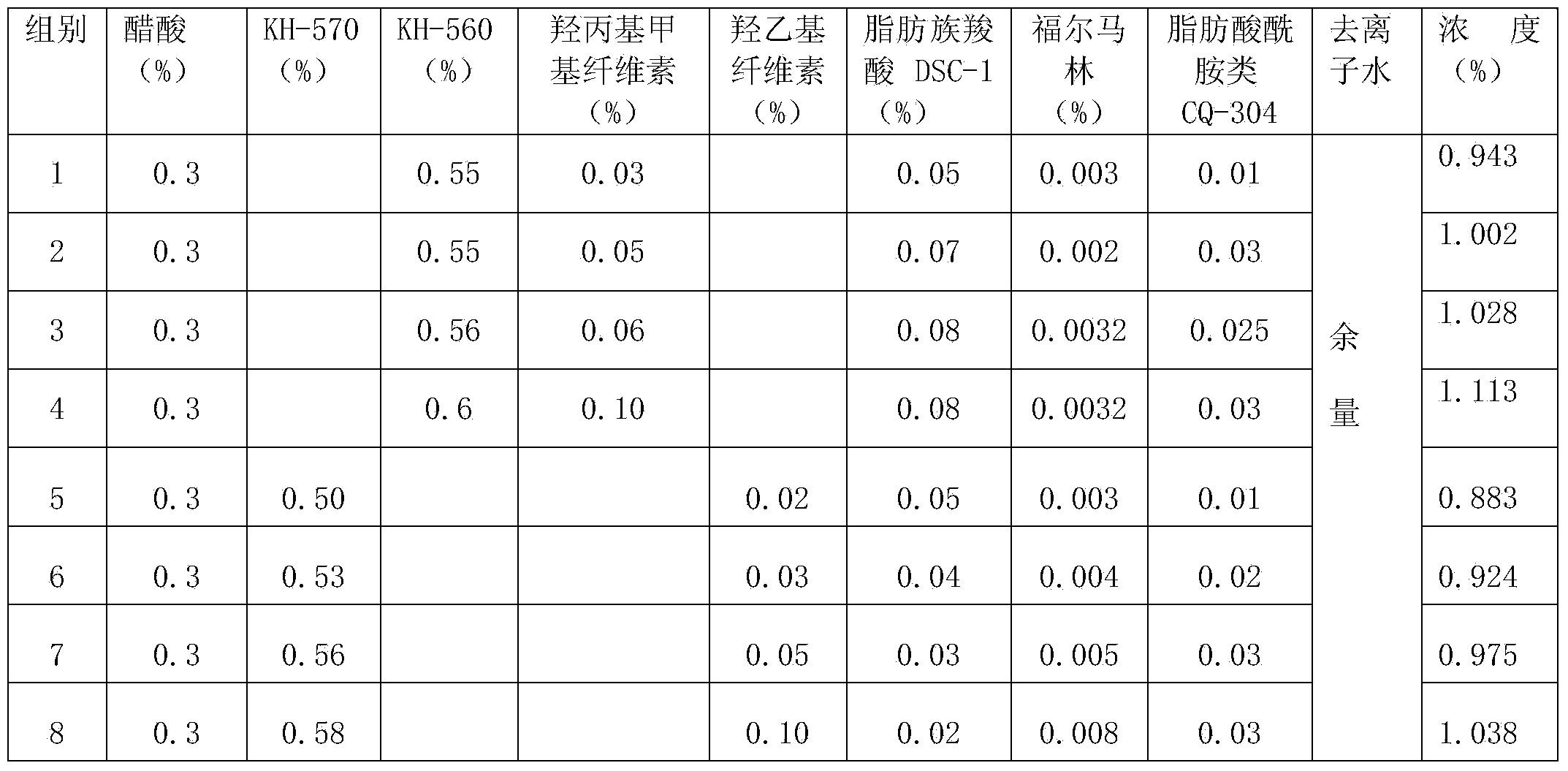

[0016] Proposed 8 components in the present embodiment, the formula of each component wet-process chopped strand sizing agent is as shown in Table 1:

[0017] Table 1

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com