Continuous carbon fiber reinforced crucible preform and preparation method thereof

A prefabricated body and carbon fiber technology, applied in the field of crucibles, can solve problems affecting the service life of crucibles, less continuous fiber content, insufficient continuous fibers, etc., and achieve the effects of good overall structural stability, shape stability, and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

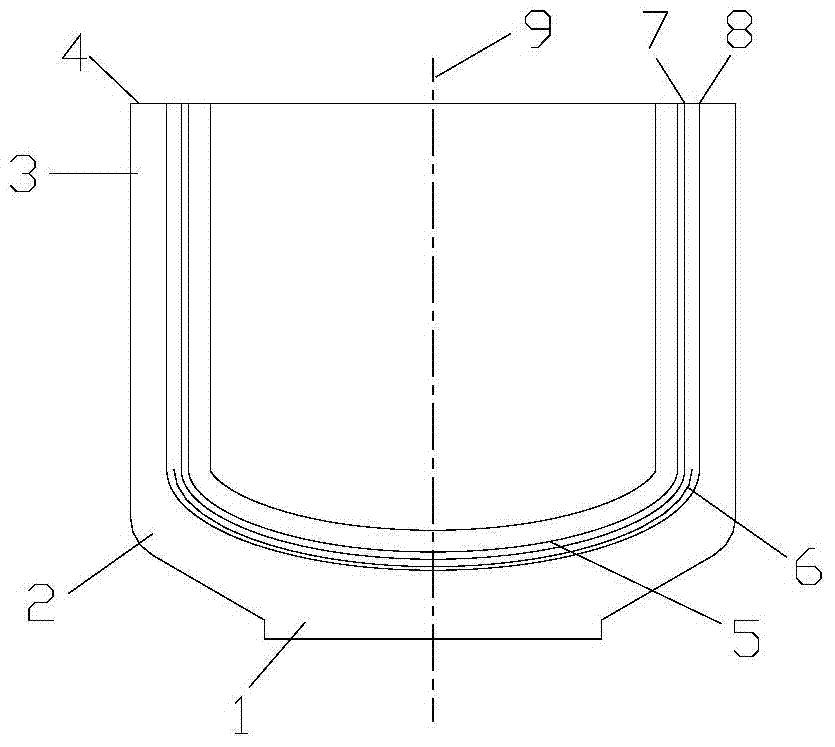

Embodiment 1

[0038] The basic unit consists of a layer of 3K plain weave carbon fiber cloth 12 and a layer density of 40g / m 2 The carbon fiber cloth / net tire compound material 10 that net tire 11 is pre-acupuncture formed, and its area density is 320g / m 2 , the pre-needling density is 2 needles / cm 2 ;

[0039] The number of cutting seams 13 of the carbon fiber cloth / net tire composite material 10 for the overall structure layer 5 is 6;

[0040] The number of cutting seams 13 of the carbon fiber cloth / net tire composite material 10 for the local reinforcement layer 6 is 6;

[0041]Fiber reinforcement method-7 continuous fibers form two equal directions (n=2) on the circumference of the beginning 4 of the crucible side. The number of parallel chords 14 formed in a single direction is 23 with a distance of 10mm. The line-surface angle α18 of the plane 16 formed by the wrapping track is 0°;

[0042] Layer design: the overall structure layer 5 is 40 layers; the local reinforcement layer 6 i...

Embodiment 2

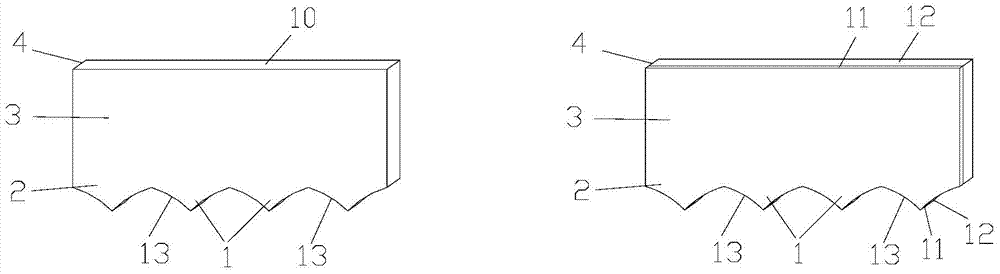

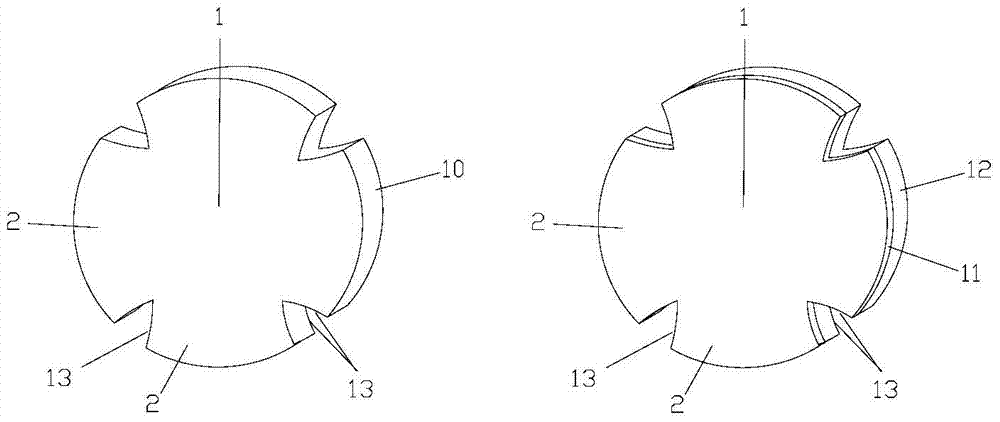

[0046] The basic unit is composed of two layers with a density of 400g / m 2 12K twill carbon fiber cloth with a layer density of 60g / m 2 12K grid tire 11 pre-needled carbon fiber cloth / net tire composite material 10, its surface density is 320g / m 2 , the pre-needling density is 3 needles / cm 2 ;

[0047] The overall structure layer 5 is 4 with carbon fiber cloth 12, the opening and cutting seam 13 quantity of net tire 11, as figure 2 shown;

[0048] The number of opening and cutting seams 13 of carbon fiber cloth 12 and mesh tire 11 for local reinforcement layer 6 is 4, as image 3 shown;

[0049] Fiber reinforcement method - 7 continuous fibers form three equal directions (n=3) on the 4th circumference of the crucible side, the number of parallel chords 14 formed in a single direction is 21, and the distance is 20mm. The line-surface angle α18 of the plane 16 formed by the wrapping track is 5°; as Figure 4 and 5 shown;

[0050] Fiber reinforcement mode 2: The central...

Embodiment 3

[0055] The basic unit is composed of a layer with a density of 320g / m 2 6K satin carbon fiber cloth 12 with a second layer density of 50g / m 2 The 12K mesh tire 11;

[0056] The overall structure layer 5 uses carbon fiber cloth 12, the number of opening and cutting seams 10 of the net tire 11 is 6;

[0057] The quantity of opening and cutting seams 10 of carbon fiber cloth 12 and mesh tire 11 for local reinforcing layer 6 is 6;

[0058] Fiber reinforcement mode 2: The central angle θ20 of the cross chord 19 formed by the continuous fibers on the circumference of the first 4 of the crucible side is 90°, and the line-plane angle β24 of the plane 22 formed by the central axis 9 and the chord 19 and the crucible side wrapping track is 30°. The total number of equally divided points m on the 4th circumference of the crucible side is 82;

[0059] Design of the number of layers: the overall structure layer 5 is 23 layers; the local reinforcement layer 6 is 9 layers; the fiber reinf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com