Antimicrobial environment-friendly transparent nitro bright finish coat and preparation method thereof

An environmentally friendly, nitro-based technology, applied in the field of nitro-based gloss finish paint and its preparation, can solve problems such as the decline in antibacterial properties of the silver ion layer, yellowing and browning of the silver ion layer, affecting appearance, etc., and achieve gloss and color retention Good, VOC content compliance, high plumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

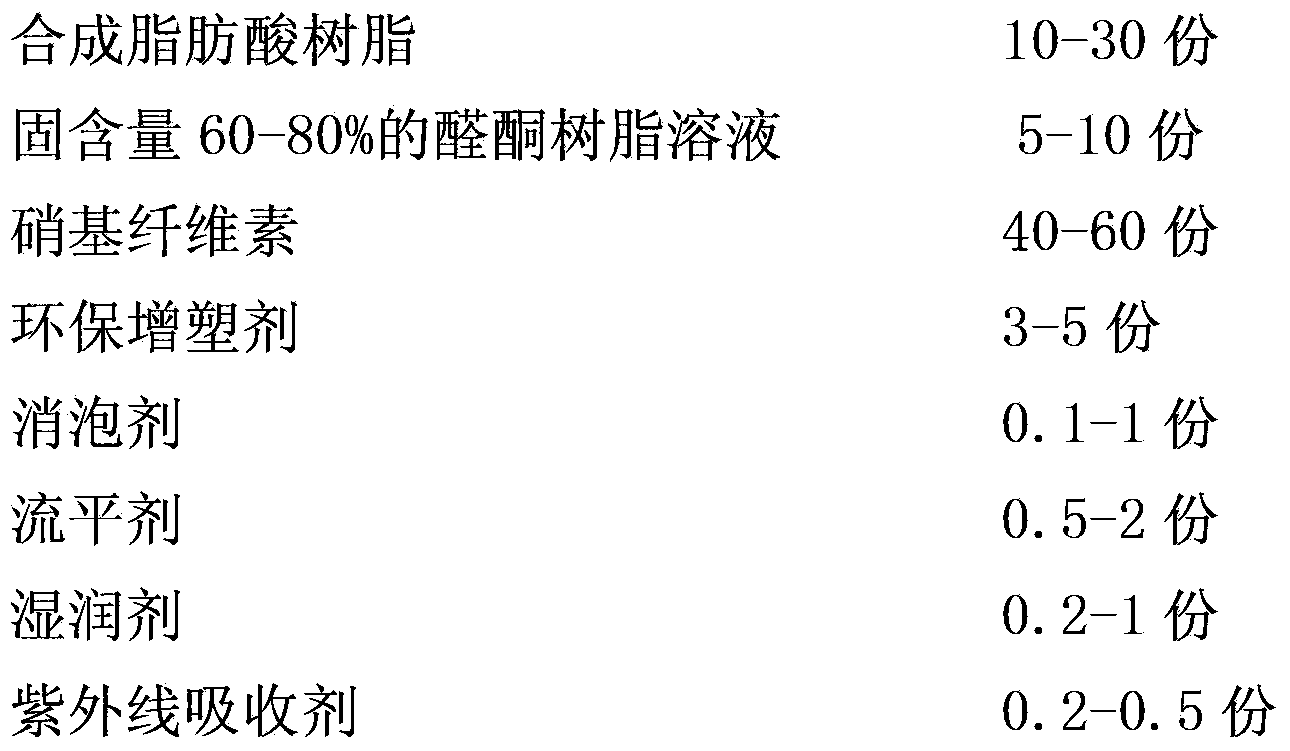

Method used

Image

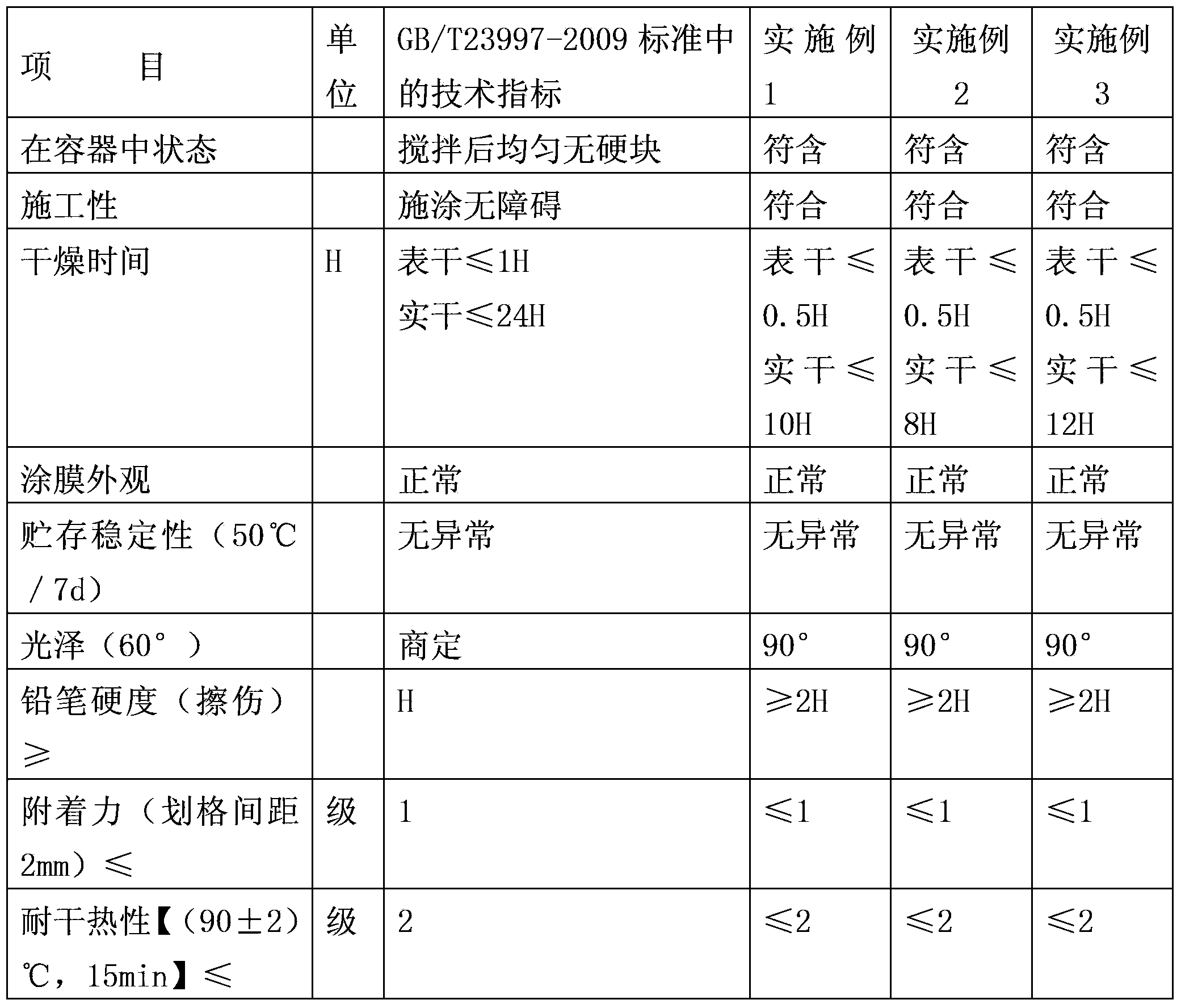

Examples

Embodiment 1

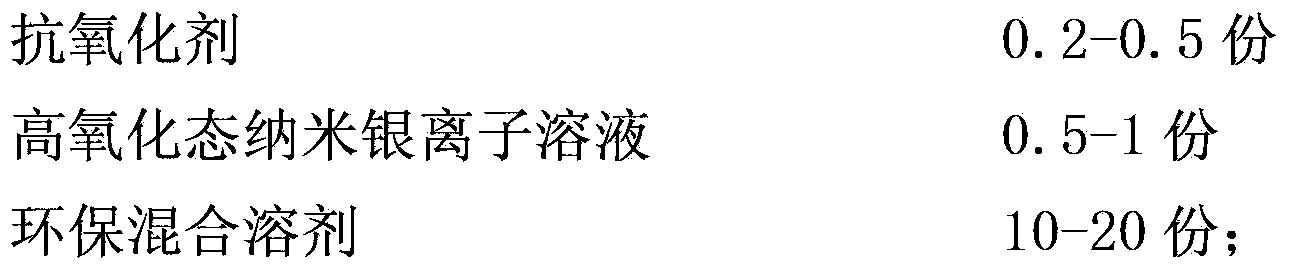

[0036] An antibacterial and environmentally friendly transparent nitro gloss finish paint, which is prepared from the main paint and thinner in a weight ratio of 1:0.5;

[0037] The main paint is prepared according to the following preparation method:

[0038] Mix 4 parts of butyl acetate, 4 parts of propylene glycol methyl ether acetate and 2.3 parts of divalent ester to form an environmentally friendly mixed solvent;

[0039] Mix 23 parts of synthetic fatty acid resin, 8 parts of aldehyde and ketone resin solution with a solid content of 60%, 19.5 parts of 1 / 2 second nitrocellulose, 32 parts of 1 / 16 second nitrocellulose, 5 parts of environmental plasticizer and environmental protection After mixing 5 parts of solvents, disperse at 700 rpm for 9 minutes; while dispersing, add 0.3 parts of defoamer, 0.5 parts of leveling agent, 0.4 parts of wetting agent, 0.3 parts of ultraviolet absorber, 0.3 parts of antioxidant, silver 0.5 parts of high-oxidized nano-silver ion solution w...

Embodiment 2

[0042] Embodiment 2 (best embodiment):

[0043] An antibacterial and environmentally friendly transparent nitro gloss finish paint, which is prepared from the main paint and thinner in a weight ratio of 1:0.9;

[0044] The main paint is prepared according to the following preparation method:

[0045] Mix 5 parts of butyl acetate, 5 parts of propylene glycol methyl ether acetate and 1 part of divalent ester to form an environmentally friendly mixed solvent;

[0046] Mix 30 parts of synthetic fatty acid resin, 10 parts of aldehyde and ketone resin solution with 70% solid content, 15 parts of 1 / 2 second nitrocellulose, 27 parts of 1 / 16 second nitrocellulose, 3 parts of environmental plasticizer and environmental protection After mixing 5.5 parts of solvent, disperse at 700 rpm for 9 minutes; while dispersing, add 1 part of defoamer, 1 part of leveling agent, 0.5 part of wetting agent, 0.5 part of ultraviolet absorber, 0.5 part of antioxidant, silver 0.5 parts of high-oxidized n...

Embodiment 3

[0050] An antibacterial and environmentally friendly transparent nitro gloss finish paint, which is prepared from the main paint and thinner in a weight ratio of 1:1;

[0051] The main paint is prepared according to the following preparation method:

[0052]Mix 7.5 parts of butyl acetate, 7.5 parts of propylene glycol methyl ether acetate and 2.1 parts of divalent ester to form an environmentally friendly mixed solvent;

[0053] Mix 20 parts of synthetic fatty acid resin, 5 parts of aldehyde and ketone resin solution with 80% solid content, 24 parts of 1 / 2 second nitrocellulose, 28 parts of 1 / 16 second nitrocellulose, 3 parts of environmental plasticizer and environmental protection After mixing 5.5 parts of solvent, disperse at 700 rpm for 9 minutes; while dispersing, add 0.3 parts of defoamer, 0.5 parts of leveling agent, 0.2 parts of wetting agent, 0.5 parts of ultraviolet absorber, 0.4 parts of antioxidant, silver 1 part of high-oxidized nano-silver ion solution with an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com