Color material under regulation and control of electric field, and preparation method of material

A technology of electric field control and medium, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of inability to realize display color control, etc., and achieve the effects of fast response speed, expanded application range, and high color brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

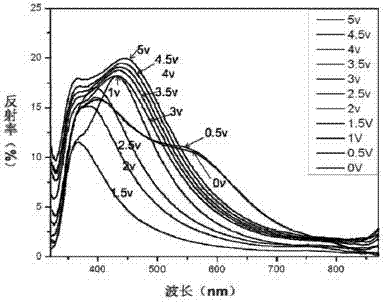

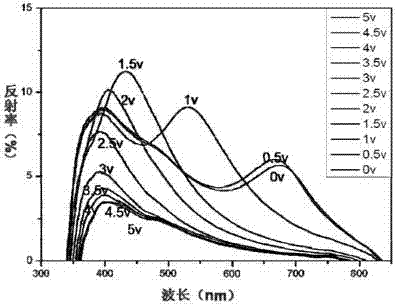

Embodiment 1

[0027] Add 8ml, 28% ammonia solution, 147ml ethanol, and 5ml water into a 500ml three-neck flask, stir at 50°C at a speed of 400r / min for 22min, then add 7.2ml tetraethyl orthosilicate dropwise with a peristaltic pump, react for 4h and then Add 38ml of ethanol, adjust the pH value to 10-11 at 50°C, and continue stirring for 10 minutes. Take out 105ml of the solution from the three-neck flask, keep 100ml of the solution, add the ethanol solution of isopropyl titanate dropwise with a peristaltic pump, including 50ml of ethanol and 1ml of isopropyl titanate, continue stirring for 1 hour after dropping, stop stirring for 2 hours , Centrifuge the reacted product to obtain SiO 2 / TiO 2 , washed once with distilled water and ethanol respectively, dried at 50°C to 80°C, and ground for use.

[0028] The silicon oxide nanoparticles coated with titanium oxide were observed by transmission electron microscope, the results can be found in figure 1 ,Depend on figure 1 It can be seen tha...

Embodiment 2

[0032] 0.096g of silicon oxide nanoparticles coated with 7nm thick titanium oxide prepared in Example 1 was dispersed in 0.5mL propylene carbonate to be tested. The test process was the same as in Example 1, and the shape of the obtained spectrum was similar to that in Example 1. , but the overall reflection peak intensity increases.

Embodiment 3

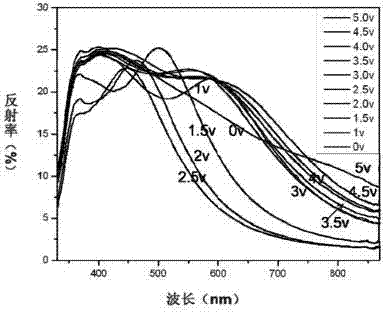

[0034] Disperse 0.0648g of silicon oxide nanoparticles coated with 7nm thick titanium oxide prepared in Example 1 in 0.5mL water to be tested. The test process is the same as in Example 1. The reflection intensity of the obtained spectrum is obviously increased to 30%, and the voltage is increased from 0v to In the process to 5v, the peak position moves from 420nm to 480nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com