Carbonizing apparatus and carbonizing method for waste solid organic matters

A technology for solid waste and organic matter, applied in fixed carbonization furnaces, biofuels, special forms of dry distillation, etc., can solve the problems of wasting resources, increasing environmental loads, and high equipment costs, and achieves low equipment costs, reduced procedures, and simple structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

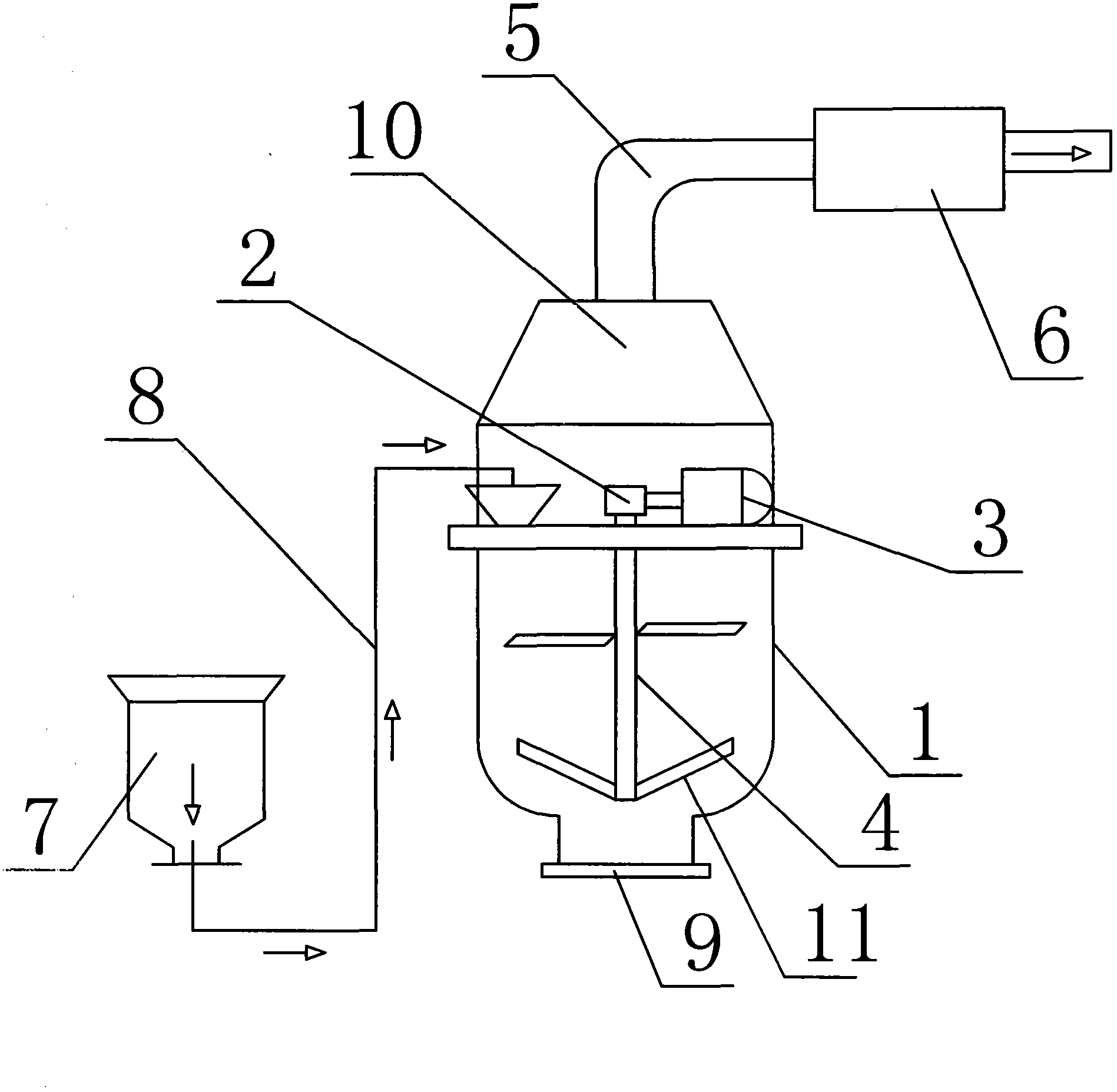

[0021] like figure 1 As shown, a method for carbonizing solid waste organic matter, the method mainly uses the carbonization reactor to carbonize the organic matter in solid waste, and the specific process steps are as follows:

[0022] ① Put the organic solid waste into the crusher 7 for crushing, transport the crushed organic solid waste to the carbonization reaction kettle 1 through the hoist 8, and add zinc chloride, potassium nitrate, and strontium nitrate;

[0023] 2. Start the carbonization reaction kettle 1, fully stir the mixture in the carbonization reaction kettle 1 evenly, and at the same time, after stirring, heat will be generated in the carbonization reaction kettle 1, and white phosphorus is added from the discharge port 9 at the bottom of the carbonization reaction kettle 1 to make The mixture in the carbonization reactor 1 is not fully combusted;

[0024] ③. Cool the insufficiently combusted mixture in the carbonization reactor 1 to finally obtain charcoal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com