Method for homoepitaxial carbon silicon double atomic layer thin film on sic substrate

A carbon-silicon diatomic, homoepitaxial technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve problems such as the impact of SiC device performance, increase film growth area, and shorten epitaxy time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

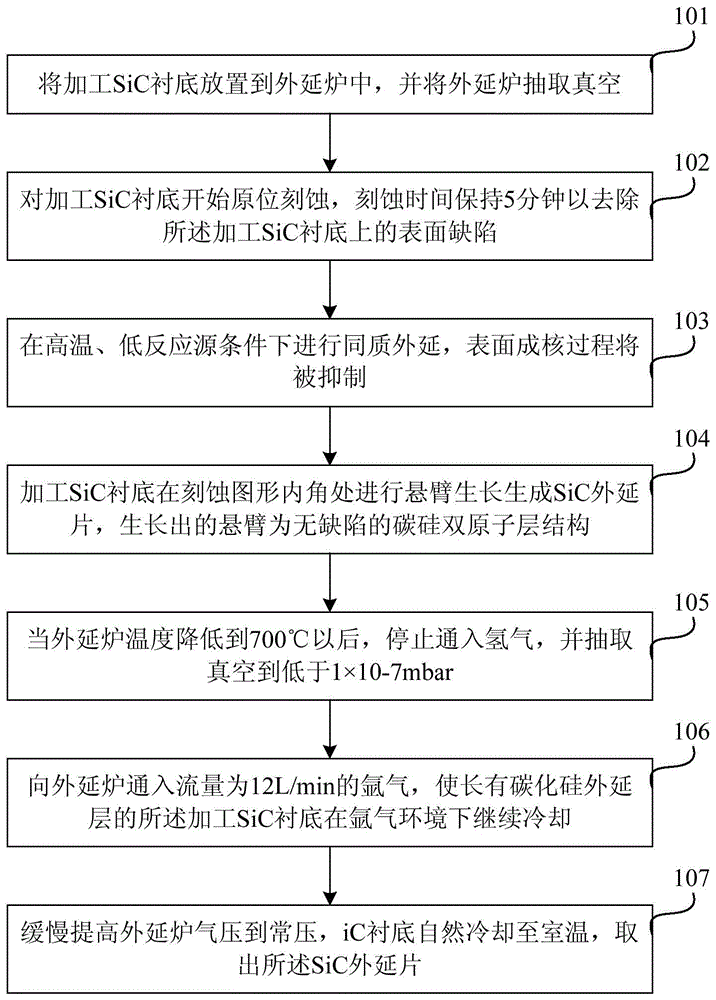

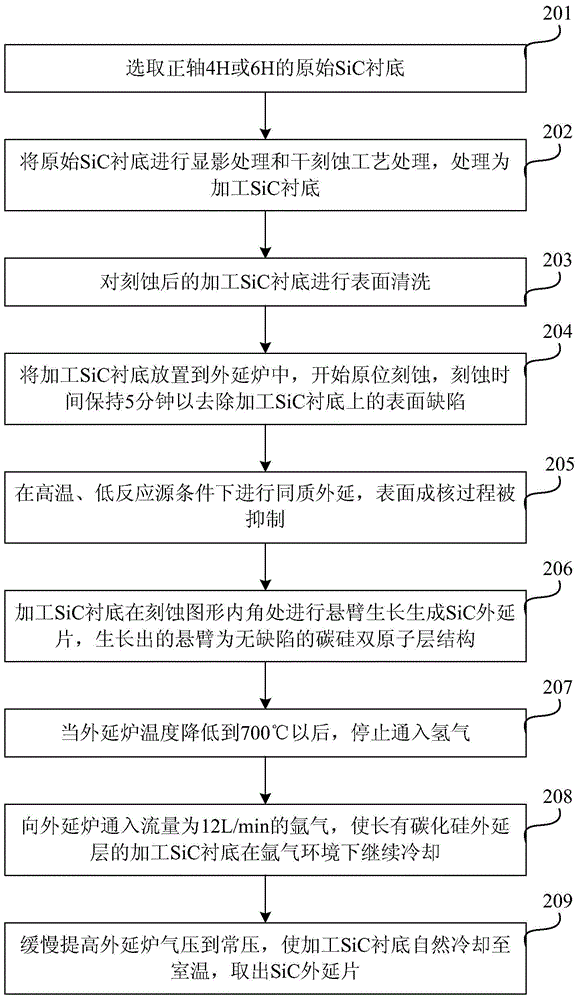

[0022] figure 1 It is a flow chart of Embodiment 1 of the method for homoepitaxial carbon-silicon double atomic layer thin film on SiC substrate of the present invention; as shown in the figure, this embodiment specifically includes:

[0023] Step 101, placing the processed SiC substrate processed by using the original SiC substrate with positive axis 4H or 6H into the epitaxial furnace, and vacuuming the epitaxial furnace;

[0024] Step 102, when the vacuum degree of the epitaxial furnace is lower than 6×10 -7 Inject hydrogen at mbar to keep the pressure at 100mbar and heat the epitaxial furnace. When the temperature reaches 1600 degrees, the hydrogen starts to etch the processed SiC substrate in situ. The etching time is kept for 5 minutes to remove the surface defects on the processed SiC substrate. ;

[0025] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com