A packaging structure and packaging method for radio frequency inductors

A packaging structure and packaging method technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of unfavorable market promotion of portable devices, process difficulty and high production cost, and affect Q value, so as to overcome process difficulty and process The effect of reducing cost and production cost and improving Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

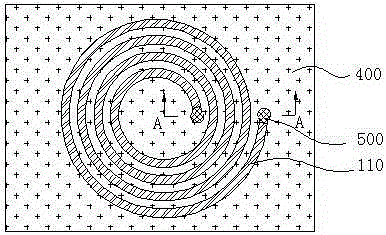

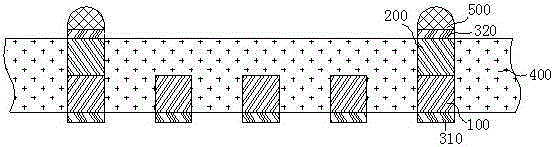

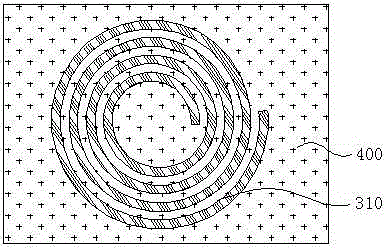

[0047] see Figure 1 to Figure 3 , is an embodiment of a packaging structure of a radio frequency inductor of the present invention, which is formed by a semiconductor packaging process. The inductance coil 110 is in a spiral shape and is formed by continuous metal wires 100 with a certain thickness and a certain gap. Metal pillars 200 vertically connected to the metal wire 100 are provided at the inner and outer ports of the metal wire 100, and the metal pillars 200 are perpendicular to the plane where the inductance coil 110 is located. The cross-section of the metal pillars 200 is circular, rectangular or polygonal. The width of the metal post 200 is not greater than the width of the metal line 100 . The gaps between the adjacent metal wires 100 and the periphery of the metal wires 100 and the metal pillars 200 are sealed with a plastic sealing material, and the plastic sealing material is a thermosetting resin. The lower surface of the metal wire 100 and the upper end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com