High-dietary fiber refined flour, production process of flour, and production process for preparing fine dried noodles by using flour

A technology of high dietary fiber and refined flour, applied in food preparation, dough processing, food science, etc., can solve the problems of not being able to meet the daily needs of the body, low dietary fiber content, etc., to improve immunity and promote calcium absorption , the effect of regulating human body functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

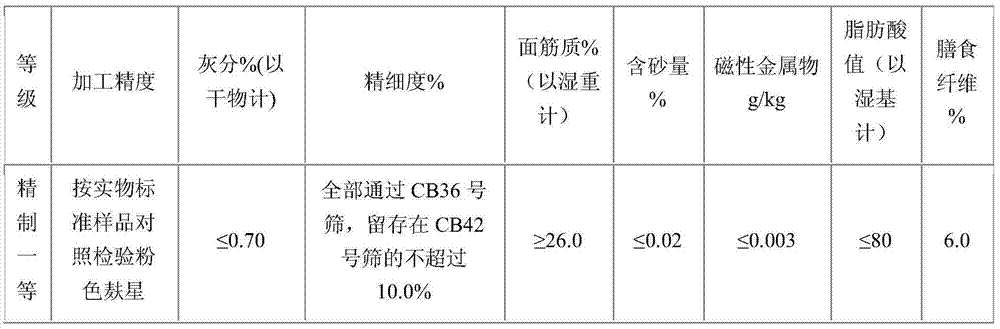

[0016] A high dietary fiber refined flour, including 93.5% wheat flour, 6.2% inulin with a polymerization degree of 3-60.

Embodiment 2

[0018] A high dietary fiber refined flour, including 93% wheat flour, 7% inulin with a polymerization degree of 3-60.

Embodiment 3

[0020] A high dietary fiber refined flour, including 95% wheat flour, 5% inulin with a polymerization degree of 3-60.

[0021] The production process of the high dietary fiber refined flour described in embodiments 1 to 3 is:

[0022] Firstly, the raw material wheat is traditionally pretreated: stone-removing magnetic separation, wheat washing and screening, stone-removing magnetic separation, wheat grinding, sieving, and milling;

[0023] Then add the inulin with a degree of polymerization of 3-60 as described in Examples 1 to 3, mix thoroughly and uniformly, and then measure and pack the finished product.

[0024] The production process of producing dried noodles from high dietary fiber refined flour described in Examples 1-3, the operation process is as follows: kneading noodles → ripening → sheeting → cutting into strips → wet cutting noodles → drying → cutting → measuring → packaging → inspection → finished dried noodles ,

[0025] The high dietary fiber refined flour a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com