Preparation method of titanium dioxide nanotube array with orientation structure

A nanotube array and titanium dioxide technology, which is applied in the field of preparation of titanium dioxide nanotube arrays, can solve problems such as weak orientation texture, heavy metals endanger the environment, and limit performance, and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] (1) First, prepare HF, HNO 3 , H 2 O polishing solution with a volume ratio of 1:4:5, immerse the titanium sheet for 60s for polishing, then wash it with deionized water, and then wash it with N 2 blow dry.

[0020] (2) Soak the pretreated titanium sheet until it contains 0.3wt%NH 4 F, 2wt%H 2 In the electrolyte solution of O and ethylene glycol (500ml), anodize at a voltage of 50V for 2h, then ultrasonically in deionized water and blown with nitrogen to remove the primary oxide film, and then anodize again in the previous electrolyte for 2h, and then Ultrasonic cleaning in isopropanol for 15 min washes away the residual electrolyte and impurities on the surface of the nanotube array.

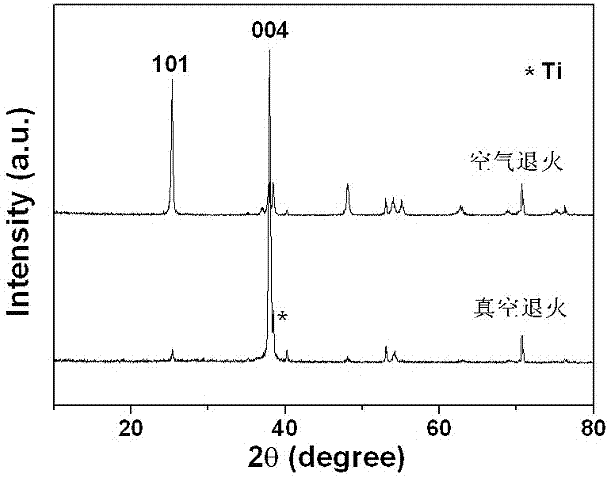

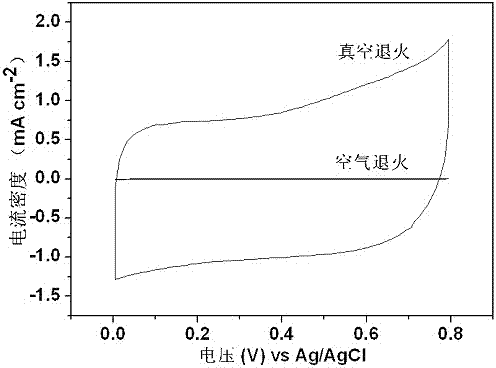

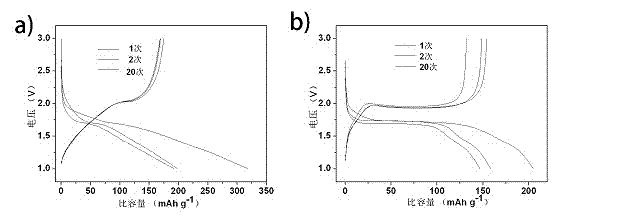

[0021] (3) Prepare TiO by secondary anodic oxidation 2 The nanotube arrays were heated in a tube furnace at a heating and cooling rate of 0.5 °C / min at 450 °C under vacuum (mechanical pump, 10 -1 Pa) Annealing and holding for 2h.

[0022] (4) The titanium dioxide nanotube array wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com