High sunlight-resistant terylene decorative cloth

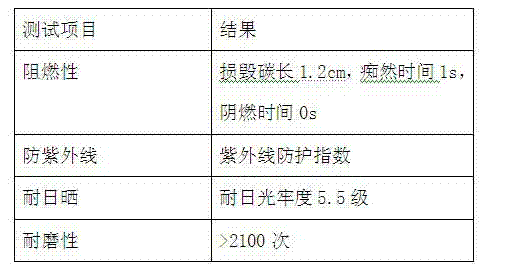

A decorative fabric and high-resistance technology, applied in the field of polyester decorative fabrics, can solve the problems of easy dusting, poor dyeability, and easy formation of holes in polyester fabrics, so as to improve the anti-ultraviolet ability, increase wear resistance and good shape retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments.

[0014] In this embodiment, 8S / 2 cotton yarn is used as the warp yarn, and 7S high-strength polyester yarn is used as the weft yarn. The warp yarn and the weft yarn are dyed respectively, and then the finished product is obtained through warping, weaving and finishing.

[0015] Warp dyeing: use Dianix AM Classies dyes, add salt or saline solution at the beginning of dyeing, add dissolved Dianix AM Classies dye solution, 1-2% leveling agent fatty alcohol polyoxyethylene ether and 1-2% anti-alcohol after 15 minutes UV agent SCJ-966, 1-2% flame retardant ammonium polyphosphate, after 85 minutes of color fixing stage, soap with 2-2.5g / L detergent at 85°C for 10-12 minutes, and then out of the tank;

[0016] Weft yarn dyeing: Dyeing with anthraquinone dyes, when the pH value is 6.2, add 1-3wt% dispersant sodium methylenebissulfonate and 0.5-2wt% level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com