Preparation method of wear-resistant and antioxidant polyphenylene sulfide filter

A polyphenylene sulfide, anti-oxidation technology, applied in chemical instruments and methods, separation methods, filtration separation and other directions, can solve the problems of limited application fields, difficult melt processability, cold flow properties, etc., to improve filtration efficiency, resistance to The effect of improving the abrasiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

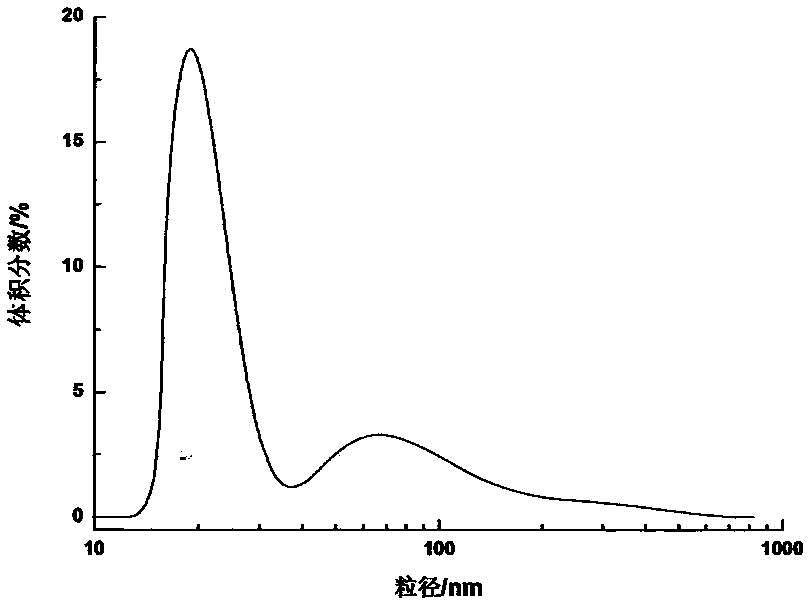

[0033] Get 90 parts of deionized water, add 4 parts of nano-SiO after vacuum drying to it 2 , ultrasonically dispersed for 30 minutes, added 0.3 parts of silane coupling agent, stirred on a magnetic stirrer for 30 minutes, and then ultrasonicated for 40 minutes. Add 0.2 parts of sodium dodecylbenzenesulfonate and 3 parts of triethanolamine, stir on a magnetic stirrer for 30 minutes, and ultrasonically disperse for 40 minutes to obtain uniformly dispersed nano-SiO 2 water dispersion. For its particle size distribution, see figure 1 .

example 2

[0035] With the nano-SiO of step (1) gained 2 The water dispersion is mixed with PTFE emulsion, adhesive, and deionized water in a certain proportion, and stirred on a magnetic stirrer for 30 minutes to obtain uniformly mixed nano-SiO in different proportions. 2 / PTFE composite treatment fluid, spare. Different configurations are shown in Table 1.

[0036] Table 1

[0037]

example 3

[0039] Soak the PPS filter material sample in a mixed solution containing 20-30g / L NaOH and 5-10g / L penetrant for pretreatment, the bath ratio is 10-20:1, heat it in a water bath, the water bath temperature is 80- 100°C. After 0.5-1.5 hours of treatment, the samples were taken out, cleaned, and dried in an oven. The treated PPS sample is completely impregnated in the different proportioning nano-SiO shown in example 2 2 / PTFE composite treatment solution, the immersion time is 0.5-1.5min, and the bath ratio is 10-20:1. The excess liquid is rolled off on a rolling car, and the excess liquid is 60-80%, and then placed in a shaping dryer for baking at a temperature of 200-260° C. for 2-3 minutes. The wear-resistant and anti-oxidation polyphenylene sulfide filter material is obtained. Nano-SiO with different formulations 2 The corresponding numbers of the PPS samples treated with / PTFE composite treatment solution are marked as 0#, 1#, 2#, 3#, 4#, 5#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com