Refining process of hydrogen chloride

A hydrogen chloride and process technology, applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical industry, etc., can solve problems affecting the purity of hydrogen chloride gas, troublesome operation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

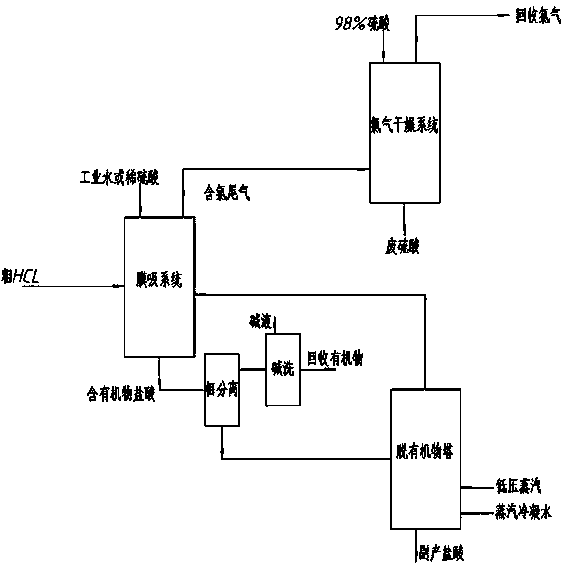

Image

Examples

Embodiment Construction

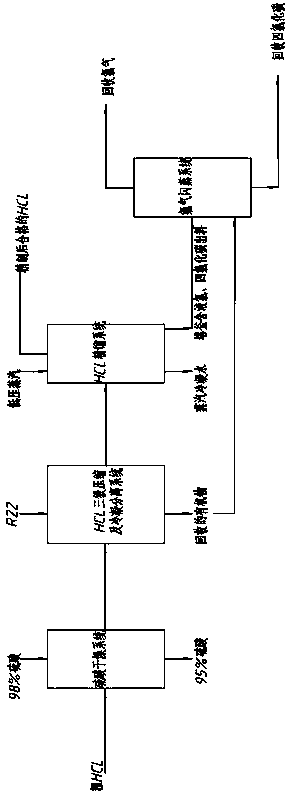

[0018] Such as figure 2 Shown, the present invention is a kind of hydrogen chloride refining process, comprises the following steps:

[0019] 1. Dry the crude hydrogen chloride through a sulfuric acid drying system at room temperature, and add 98%wt sulfuric acid into the sulfuric acid drying system to remove the moisture in the crude hydrogen chloride gas. After defogging through the mist eliminator, the gas does not contain water and sulfuric acid, and then the gas with water removed is compressed and condensed in three stages to separate the system. After drying, the sulfuric acid concentration in the sulfuric acid drying system is about 95%wt.

[0020] The compressors of the second and third stage compression and condensation separation systems adopt D-type two-row three-stage compression differential oil-free hydrogen chloride compressors. Among them, the exhaust pressure of the first stage compression is 0.23-0.3MPaG. The gas after the first stage compression is first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com