Oxidation ditch nitrogen and phosphorus removal sewage treatment system and technology thereof

A technology for sewage treatment system and denitrification and dephosphorization, which is applied in the field of denitrification and dephosphorization sewage treatment system, can solve the problems of difficulty in maintaining high concentration of microorganisms in oxidation ditch, limited sewage treatment capacity, waste of facilities and equipment, etc. Processing capacity, ensure the air flotation effect, the effect of short hydraulic retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

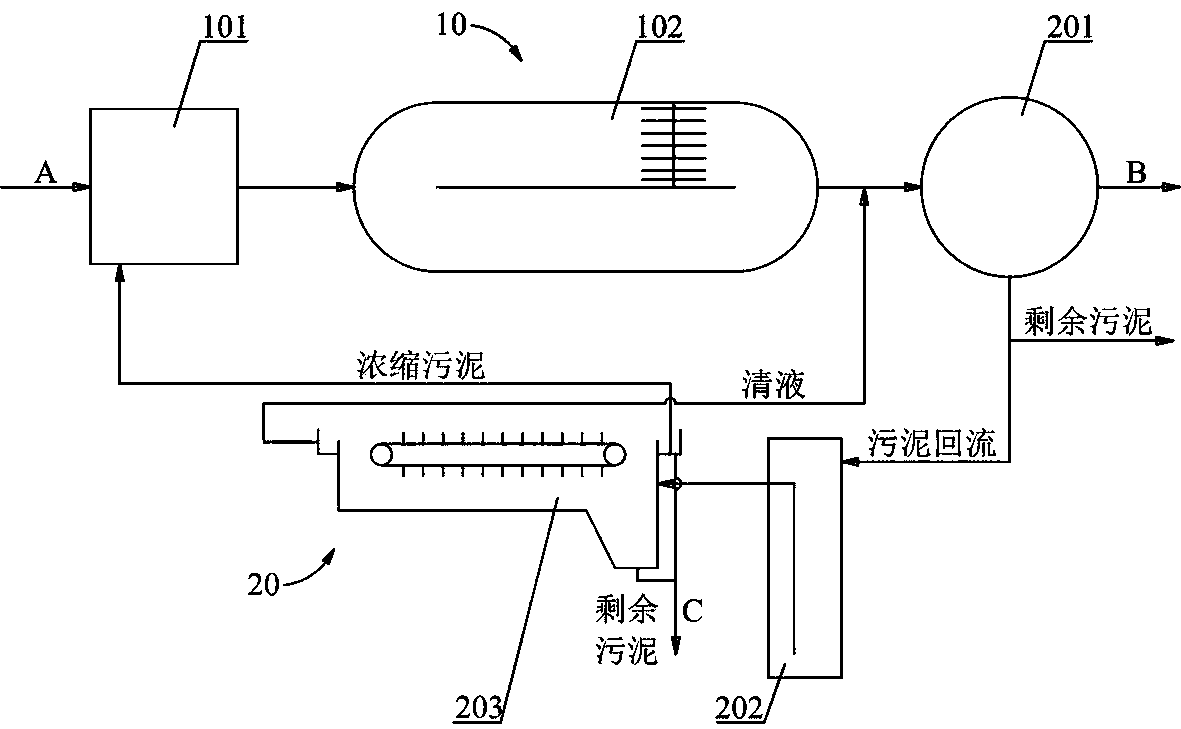

[0027] Embodiment one: combine below figure 1 Illustrate the oxidation ditch denitrification and phosphorus removal sewage treatment system of the present embodiment, it comprises the denitrification and phosphorus removal reaction unit 10 and the solid-liquid separation unit 20 that are connected, and the denitrification and phosphorus removal reaction unit 10 comprises the anaerobic tank 101 and The oxidation ditch 102 and the solid-liquid separation unit 20 include a secondary settling tank 201 , a deep dissolved air tank 202 and an air flotation tank 203 connected in sequence, and the output end of the oxidation ditch 102 is connected with the input end of the secondary settling tank 201 .

[0028] Further, the air flotation tank 203 communicates with the input end of the anaerobic tank 101 through a pipeline.

[0029] In the denitrification and phosphorus removal reaction unit 10, the input end of the anaerobic tank 101 is connected with the sewage inlet A, and the sewage...

Embodiment 2

[0035] Embodiment two: combine below figure 1 The oxidation ditch denitrification and phosphorus removal wastewater treatment process of the present embodiment includes the following steps:

[0036] 1. Anaerobic phosphorus release reaction: Sewage first enters the anaerobic zone 101, and the sewage to be treated is mixed with the concentrated sludge returned to the anaerobic zone 101 from the air flotation tank 203. The hydraulic retention time is 1.5h, and anaerobic phosphorus release reaction occurs; the activated sewage The phosphorus accumulating bacteria in the mud degrade the phosphorus-accumulating particles (poly-P) in the body to generate energy and release phosphate. At the same time, the phosphorus accumulating bacteria absorb the short-chain fatty acids in the sewage to form PHB and store them in the cells.

[0037] 2. Nitrification and denitrification reaction: the effluent of the anaerobic pool 101 enters the anoxic zone of the oxidation ditch 102, and the denitr...

Embodiment 3

[0044] Example Three: Combining figure 1 Illustrate the oxidation ditch denitrification and dephosphorization sewage treatment process of the present embodiment, and embodiment two is different, in step four, the depth of dissolved air deep pool 202 is 30m, and the air supply position of air compressor is 20m away from liquid surface; Step In step five, the conveying ratio of concentrated activated sludge accounts for 60% of the total amount of return sludge in step four.

[0045] Based on the concentration of activated sludge in the air flotation tank of 20000mg / L, when the reflux ratio is 60%, according to the above formula, the concentration of concentrated sludge in the denitrification and phosphorus removal reaction unit is 7500mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com