Natural fiber/polylactic acid composite material and preparation method thereof

A technology of natural fibers and composite materials, applied in the field of natural fiber reinforced polylactic acid and its preparation, can solve the problems of complex operation, difficult industrialization, and high equipment requirements, achieve simple methods, improve compatibility, and enhance mechanical properties and thermal properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

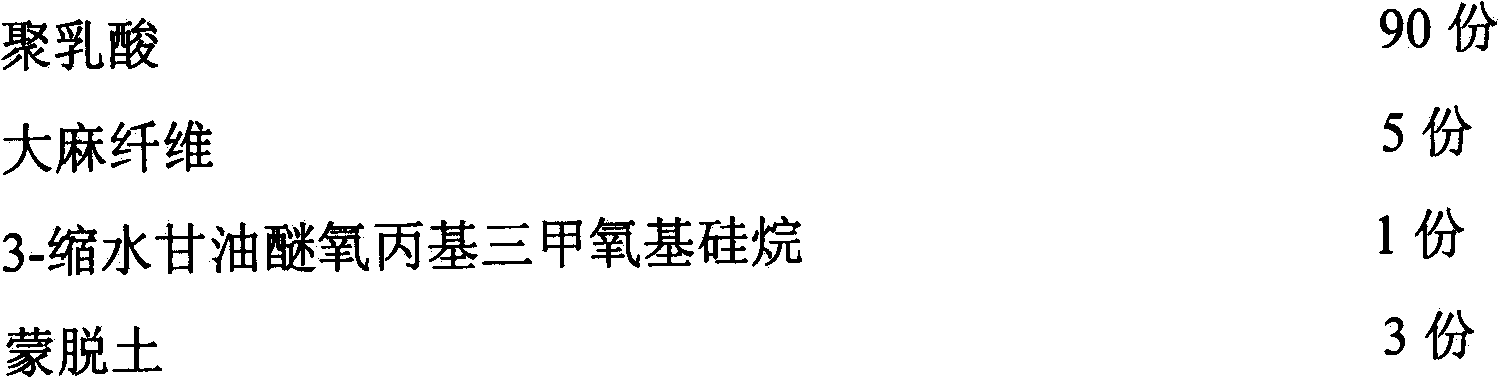

[0027] The biodegradable natural fiber / polylactic acid composite material in this embodiment is made of components comprising the following parts by weight:

[0028]

[0029] The preparation method of the composite material of the present embodiment is as follows:

[0030] Weigh the components of each part by weight according to the above proportion, and dry the polylactic acid, hemp fiber and montmorillonite at a drying temperature of 80°C and a drying time of 10 hours; Blending in a feeder for 10 minutes, and then melt blending and extruding the mixture through a twin-screw extruder at an extrusion temperature of 180° C. to obtain natural fiber / polylactic acid composite material particles. Sample preparation and performance testing were carried out in accordance with the requirements of ASTM D638, D790 and D1525. The test results are shown in Table 1.

Embodiment 2

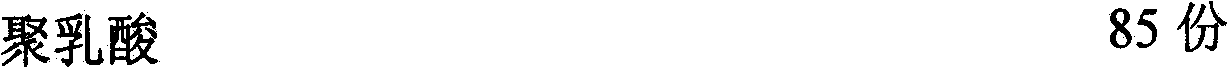

[0032] The biodegradable natural fiber / polylactic acid composite material in this embodiment is made of components comprising the following parts by weight:

[0033]

[0034]

[0035] The preparation method of the composite material of the present embodiment is as follows:

[0036] Weigh the components of each part by weight according to the above proportion, and dry the polylactic acid, jute fiber and talcum powder at a drying temperature of 60°C and a drying time of 12 hours; mix the dried raw materials according to the above ratio In-machine blending for 6 minutes, and then melt blending and extruding the mixture through a twin-screw extruder at an extrusion temperature of 200° C. to obtain natural fiber / polylactic acid composite material particles. Sample preparation and performance testing were carried out in accordance with the requirements of ASTM D638, D790 and D1525. The test results are shown in Table 1.

Embodiment 3

[0038] The biodegradable natural fiber / polylactic acid composite material in this embodiment is made of components comprising the following parts by weight:

[0039]

[0040] The preparation method of the composite material of the present embodiment is as follows:

[0041] Weigh the components in parts by weight according to the above ratio, and dry the polylactic acid, sisal fiber and kaolin at a drying temperature of 70°C and a drying time of 8 hours; mix the dried raw materials according to the above ratio The mixture was blended in the machine for 5 minutes, and then the mixture was melt-blended and extruded through a twin-screw extruder at an extrusion temperature of 190° C. to obtain natural fiber / polylactic acid composite material particles. Sample preparation and performance testing were carried out in accordance with the requirements of ASTM D638, D790 and D1525. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com