Oxidation desulfurization method based on Lewis acid ion liquid

An acidic ionic liquid and oxidative desulfurization technology, which is applied in the fields of refining oxygenated compounds, petroleum industry, refining hydrocarbon oil, etc., can solve the problems of difficult recovery of acid catalysts, fuel oil pollution, catalyst loss, etc., and achieve broad practical industrial application prospects , Overcome the effect of recycling difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

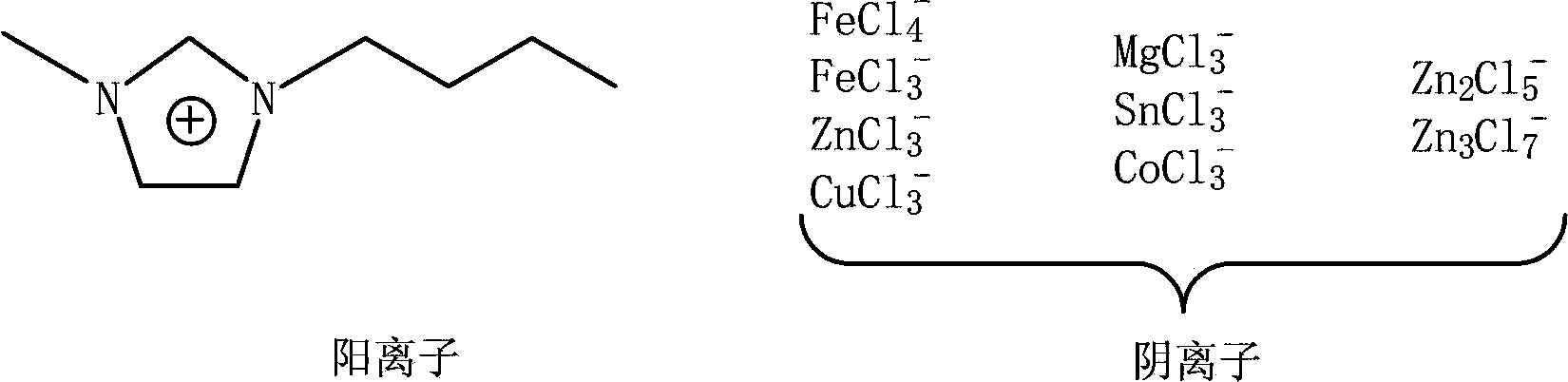

Method used

Image

Examples

Embodiment 1

[0012] 6g [Bmim]Cl / FeCl 3 , 1-Butyl-3-methylimidazolium chloride / FeCl 3 , added to 12g simulated diesel oil (the sulfur compound is dibenzothiophene, the sulfur content is 505ppm), and then added 0.17gH 2 o 2 The aqueous solution (30%) was magnetically stirred at 318K and normal pressure for 10 minutes, then stood still, separated, and detected by high performance liquid chromatography. The results showed that the sulfur content in the fuel oil was reduced to 12ppm, and the desulfurization rate was 97.7%. After the desulfurization is completed, the ionic liquid phase is separated, and the ionic liquid is back-extracted with carbon tetrachloride, poured and separated, and the ionic liquid is vacuum-dried at 80° C. to obtain a regenerated ionic liquid for the next recycling; Carbon chloride gives the product sulfone.

Embodiment 2

[0014] 6g [Bmim]Cl / 2ZnCl 2 , 1-Butyl-3-methylimidazolium chloride / 2ZnCl 2 , added to 12g simulated diesel oil (the sulfide is dibenzothiophene, the sulfur content is 505ppm), and then 0.17g H 2 o 2 The aqueous solution (30%) was magnetically stirred at 318K and normal pressure for 3 hours, then stood still, separated, and detected by high performance liquid chromatography. The results showed that the sulfur content in the fuel oil was reduced to 15ppm, and the desulfurization rate was 96.9%. After the desulfurization is completed, the ionic liquid phase is separated, and the ionic liquid is back-extracted with carbon tetrachloride, poured and separated, and the ionic liquid is vacuum-dried at 80° C. to obtain a regenerated ionic liquid for the next recycling; Carbon chloride gives the product sulfone.

Embodiment 3

[0016] 6g [Bmim]Cl / 3ZnCl 2 , 1-Butyl-3-methylimidazolium chloride / 3ZnCl 2 , added to 12g simulated diesel oil (the sulfide is dibenzothiophene, the sulfur content is 521ppm), and then 0.17g H 2 o 2 The aqueous solution (30%) was magnetically stirred at 363K and normal pressure for 3 hours, then stood still, separated, and detected by high performance liquid chromatography. The results showed that the sulfur content in the fuel oil was reduced to 4ppm, and the desulfurization rate was 99.2%. After the desulfurization is completed, the ionic liquid phase is separated, and the ionic liquid is back-extracted with carbon tetrachloride, poured and separated, and the ionic liquid is vacuum-dried at 80° C. to obtain a regenerated ionic liquid for the next recycling; Carbon chloride gives the product sulfone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com