Production method of instant pork chops

A production method and technology of pork chops, which are applied in the field of food manufacturing, can solve problems such as insufficient nutrition and health, greasy and easy to get angry, short shelf life, etc., and achieve the effect of improving volatile characteristics, removing fishy smell, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Based on 5kg pork ribs

[0042] 1) Select the best pork chops, remove the corners and bones, and check the meat quality after cleaning;

[0043] 2) Pre-boil in the water with material A for 8 minutes after flying water; the material A is made of cooking wine,

[0044] 3) After the pre-cooked pork chops are cut into pieces, add material B and stir for 10-15 minutes, then add material C and stir for 10-25 minutes;

[0045] For material B, sieve hawthorn kernel powder and soak it in cooking wine. After 40 minutes, filter off the powder residue, add perilla powder and comfrey powder into the filtrate, soak for 2 hours, and set aside; add honeysuckle before use Stir the dry powder and honey evenly, and the weight ratio of the raw materials in material B is: cooking wine: hawthorn kernel powder: perilla powder: comfrey powder: honeysuckle dry powder: honey is 100:0.6:2:0.6:0.2:12;

[0046] The ratio of material B to pork chops is: 1:0.05 according to the mass ratio;

[004...

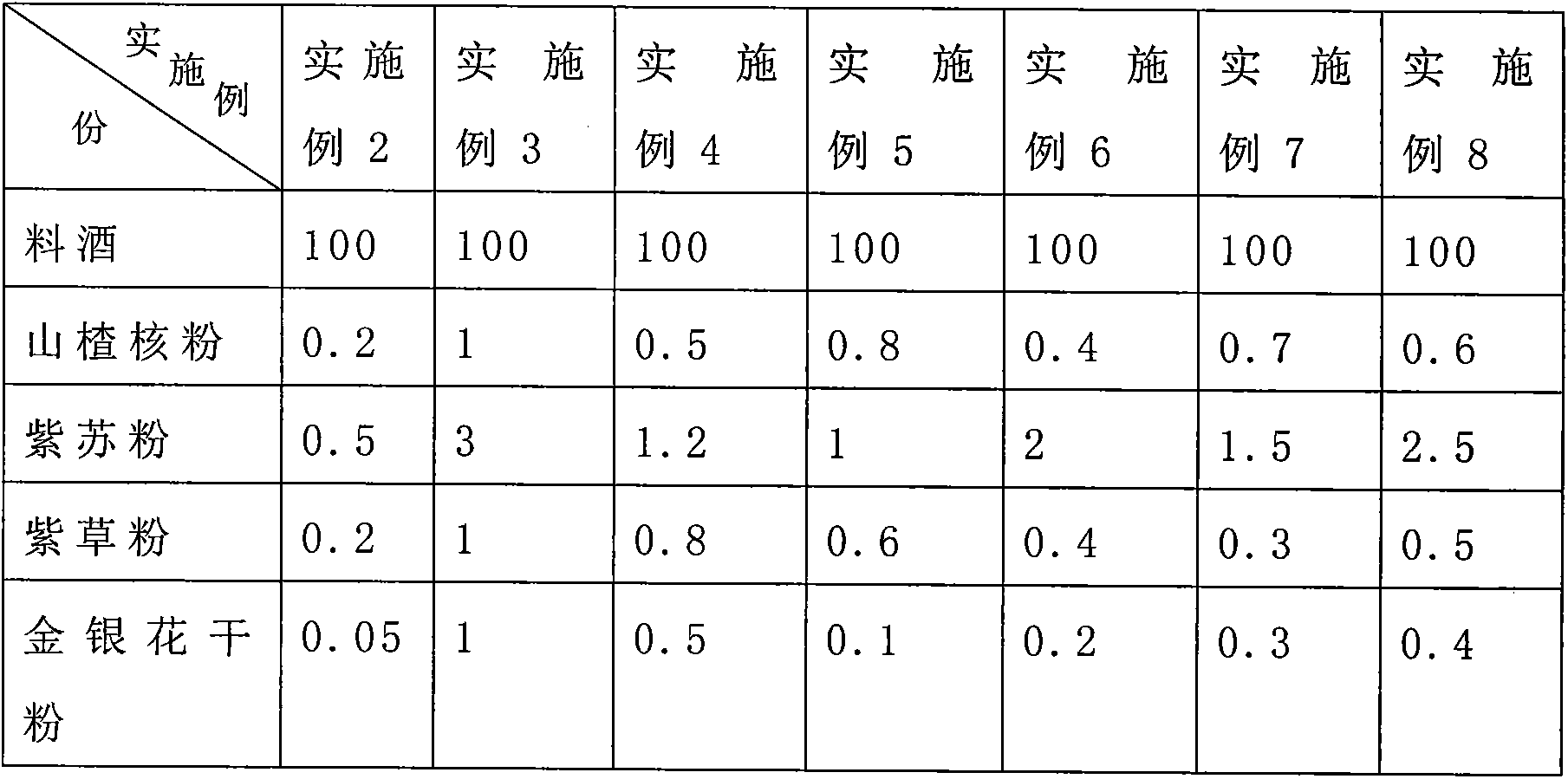

Embodiment 2-8

[0076] Described C material comprises the batching in following table, all the other are with embodiment 1.

[0077]

[0078]

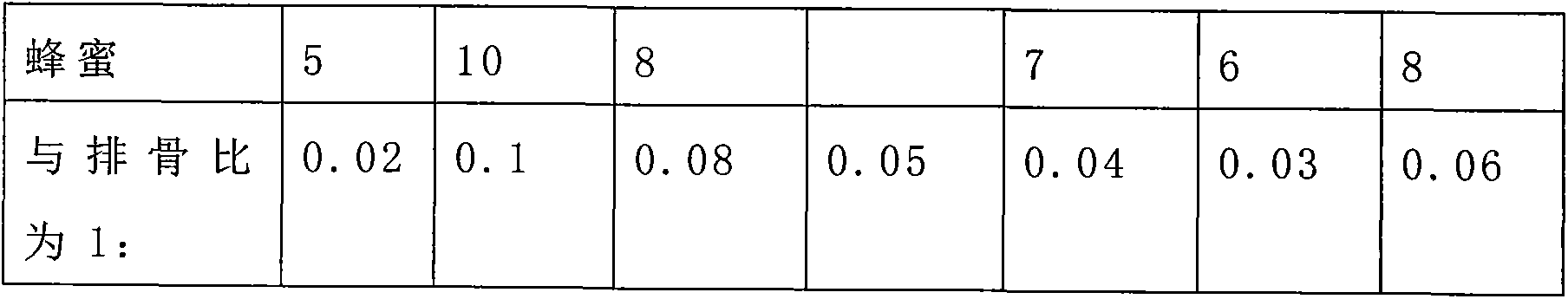

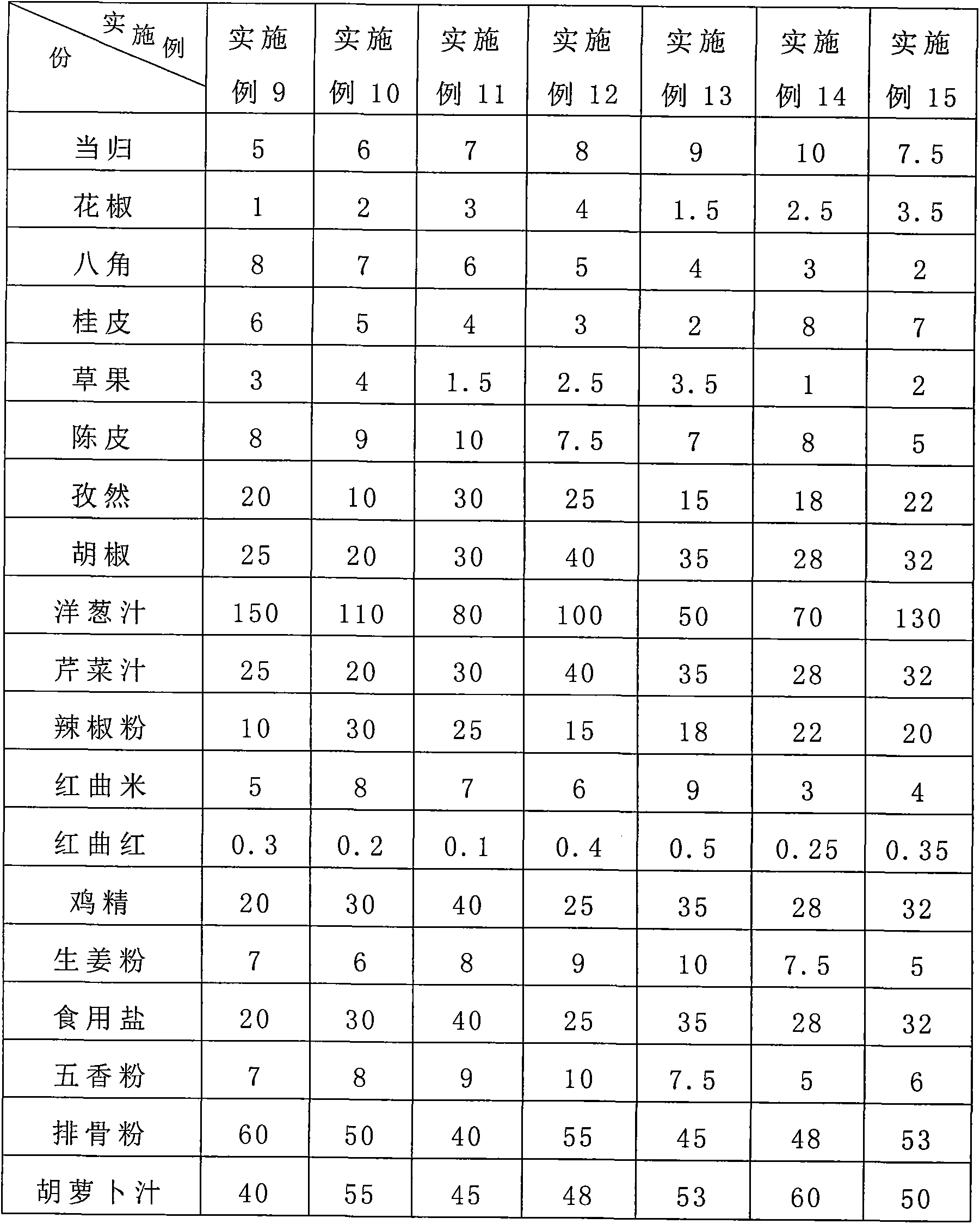

Embodiment 9

[0080] Described C material comprises the batching in following table, all the other are with embodiment 1.

[0081]

[0082]

[0083] The shelf life evaluation of stewed meat products in sauce generally uses microbial indicators. The total number of colonies ≤ 80000cfu / g is qualified, and if ≥ 80000cfu / g is unqualified. Generally, the phenomenon that the microbial index exceeds the standard will begin to appear after 3 hours of storage at room temperature (20-25 degrees Celsius). After a day or so, the meat becomes sour and rancid. If no preservatives are added, although only vacuum packaging can inhibit the growth and reproduction of aerobic microorganisms, it cannot inhibit the growth and reproduction of anaerobic microorganisms at room temperature. Therefore, only vacuum packaging has a longer shelf life than non-packaging. In about 2 days.

[0084] The experiments shown in the following table were carried out at a constant temperature of 25°C. The total number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com