Preparation method and application of high-stability zinc-iodine battery and electrode material

An electrode material, battery cathode technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of reduced capacity and coulombic efficiency, hinder development and application, etc., to improve poor cyclability, reduce solubility, and high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A highly stable zinc-iodine battery and its preparation method and application, comprising the following steps:

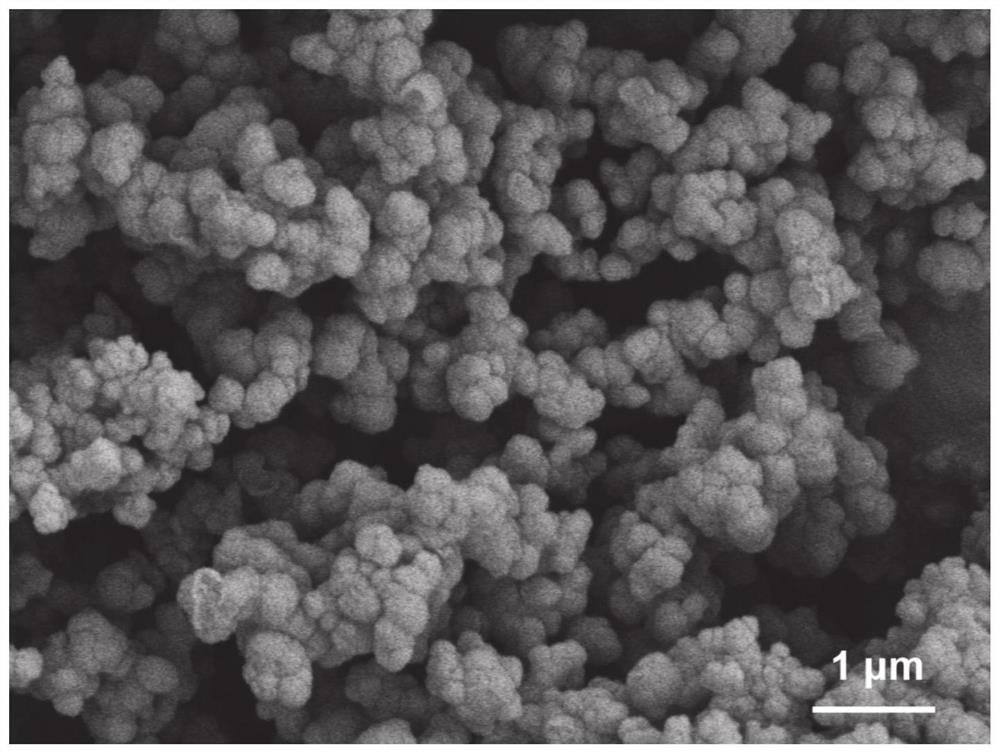

[0041] (1) Preparation of covalent organic framework compound: the covalent organic framework compound of the composite material is polyimide covalent organic framework compound COF-LZU1.

[0042] 0.30 mmol of 1,3,5-triformylbenzene and 0.45 mmol of 1,4-diaminobenzene were dissolved in 3 mL of 1,4-dioxane, and then 0.6 mL of 3 mol L-1 dilute acetic acid was added to the mixture , stirred on a magnetic stirrer for 5 days, and then the obtained product was washed with dimethylformamide and tetrahydrofuran in a centrifuge at 2000r / min for 3 times, and then the powder was kept in a vacuum oven at 80 degrees Celsius for 12 hours, and dried , that is, COF-LZU1 powder.

[0043] The active material was mixed with conductive carbon black and PVDF binder at a ratio of 6:2:2 for 12 hours, then coated on carbon paper, kept in a vacuum oven at 40 degrees Celsius for 24 ...

Embodiment 2

[0048] A highly stable zinc-iodine battery and its preparation method and application, comprising the following steps:

[0049] (1) Preparation of covalent organic framework compound: the covalent organic framework compound of the composite material is polyimide covalent organic framework compound COF-LZU1, and the steps are as described in Example 1.

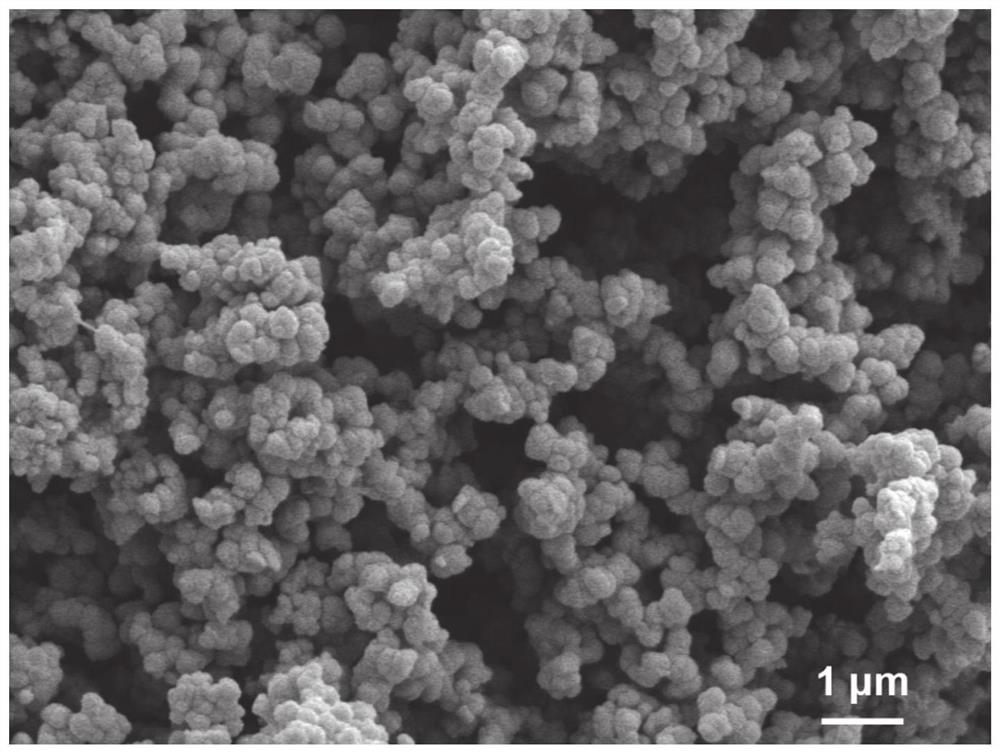

[0050] (2) After grinding the elemental iodine with a mortar, weigh 0.1g elemental iodine powder, grind it evenly with 0.1g COF-LZU1 powder, then put it into a tube furnace, and raise the temperature at a constant heating rate of 2°C / min to 80 degrees Celsius, under the protection of argon for 12 hours, the COF-LZU1 zinc-iodine battery positive electrode loaded with iodine is obtained.

[0051] The active material and MXene colloidal solution are mixed evenly in a ratio of 1:1, filtered, and kept in a vacuum oven at 40 degrees Celsius for 24 hours, and dried to obtain a positive electrode sheet, in which MXene acts as a conduct...

Embodiment 3

[0054] A highly stable zinc-iodine battery and its preparation method and application, comprising the following steps:

[0055] (1) Preparation of covalent organic framework compound: the covalent organic framework compound of the composite material is polyimide covalent organic framework compound COF-LZU1, and the steps are as described in Example 1.

[0056] (2) After grinding the iodine element with a mortar, weigh 0.1g of zinc iodide powder, grind it with 0.1g of COF-LZU1 powder evenly, then put it into a tube furnace, and raise the temperature at a constant heating rate of 2°C / min To 80 degrees Celsius, under the protection of argon for 12 hours, the COF-LZU1 zinc iodide loaded zinc iodide battery cathode active material is obtained.

[0057] (3) The active material and the MXene colloidal solution are mixed evenly in a ratio of 1:1, filtered, and kept in a vacuum oven at 40 degrees Celsius for 24 hours, and dried to obtain a positive electrode sheet, in which MXene acts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com