Tobacco extracting solution concentrating method

A technology of tobacco extraction liquid and concentration device, which is applied in separation methods, chemical instruments and methods, and solid adsorbent liquid separation, etc., can solve the problems of affecting concentration efficiency, volatilization of aroma components, and easy formation of heating tanks, and achieves improved performance. Concentration efficiency, lowering the concentration temperature, and the effect of inhibiting and removing the growth of scale particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for concentrating tobacco extract, including the following steps:

[0020] 1) Add 0.3% S-2 type adsorption clarifier (purchased from Jiangxi Yichun Yuanda Biological Co., Ltd.) into the tobacco extract by weight, react for 10 minutes and separate by butterfly separator, and collect the tobacco extract;

[0021] 2) Preheat the separated tobacco extract to 40°C;

[0022] 3) Pump the preheated tobacco extract into the heating tank, turn on the ultrasonic transmitter on the outer wall of the heating tank, and select a frequency of 20KHz and a power of 100W for vacuum concentration;

[0023] 4) Calculate the time required to concentrate 1 ton of 25°Be tobacco extract is reduced from 100 minutes in the original process to 78 minutes, and the concentration efficiency is increased by 22%.

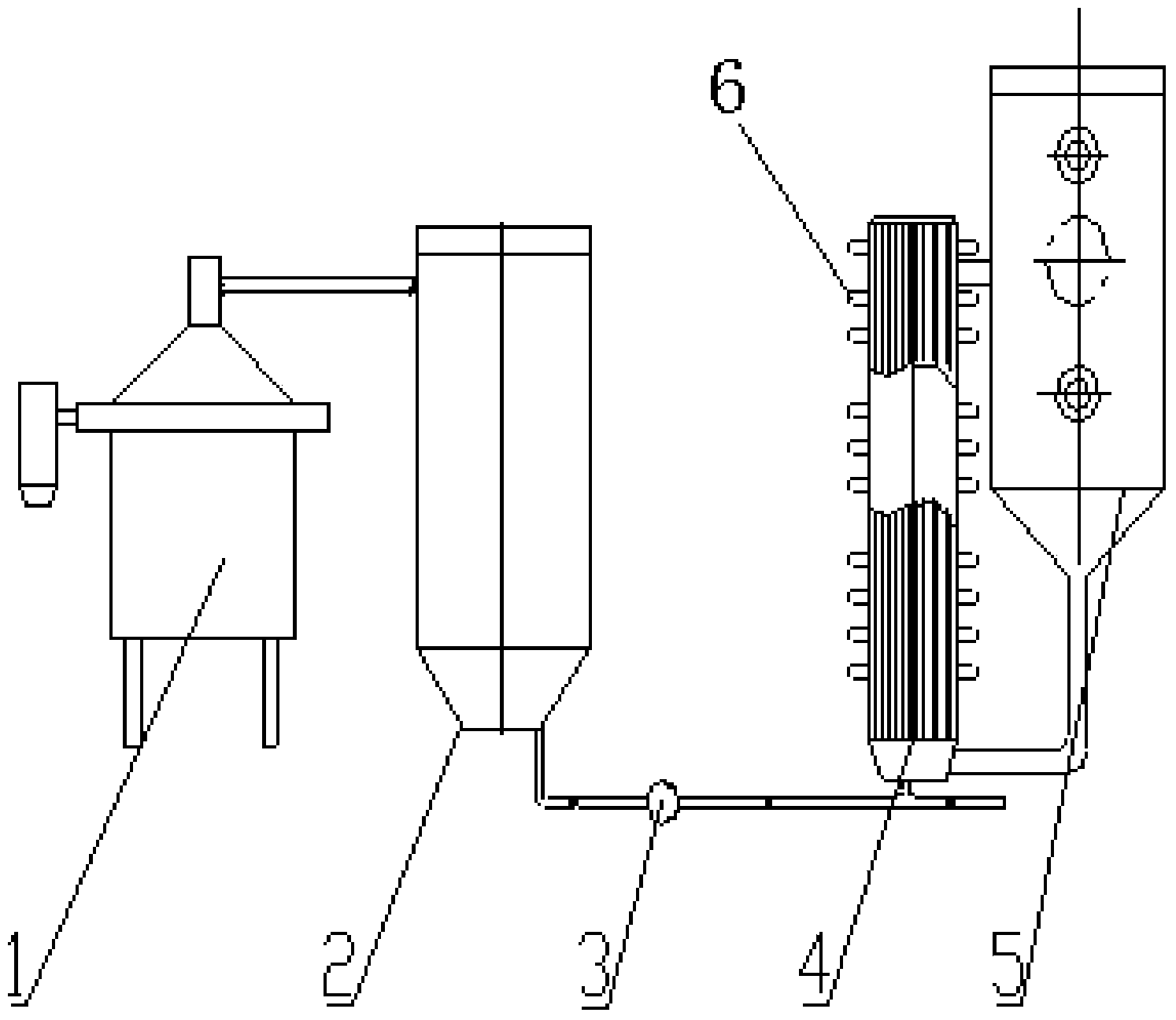

[0024] Vacuum concentration device such as figure 1 As shown, it includes a disc separator 1, a preheating tank 2, a pump 3, a heating tank 4, and a vacuum chamber 5. The discharge port of t...

Embodiment 2

[0027] A method for concentrating tobacco extract, including the following steps:

[0028] 1) Add 0.4% S-2 type adsorbent clarifier by weight to the tobacco extract, react for 20 minutes and separate by butterfly separator, and collect the tobacco extract;

[0029] 2) Preheat the separated tobacco extract to 60°C;

[0030] 3) Pump the preheated tobacco extract into the vacuum concentration heating tank, turn on the ultrasonic transmitter on the heating outdoor wall, and select the frequency of 50KHz and power of 600W for vacuum concentration;

[0031] 4) Calculate that the time required to concentrate 1 ton of 25°Be tobacco extract is reduced from 120 minutes in the original process to 80 minutes, and the concentration efficiency is increased by 33.3%.

Embodiment 3

[0033] A method for concentrating tobacco extract, including the following steps:

[0034] 1) Add 0.5% S-2 type adsorption clarifier (purchased from Jiangxi Yichun Yuanda Biological Co., Ltd.) into the tobacco extract by weight, react for 30 minutes and separate by butterfly separator, and collect the tobacco extract;

[0035] 2) Preheat the separated tobacco extract to 50°C;

[0036] 3) Pump the preheated tobacco extract into the vacuum concentration heating tank, turn on the ultrasonic transmitter on the heating outdoor wall, and select the frequency of 100KHz and power of 2500W for vacuum concentration.

[0037] 4) Calculate that the time required to concentrate 1 ton of 25°Be tobacco extract is reduced from 150 minutes in the original process to 82 minutes, and the concentration efficiency is increased by 45.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com